Executive Q&A Viewpoint: SeaOne expands South American energy options with Compressed Gas Liquid technology

SeaOne is a midstream infrastructure and logistics company that leverages its patented Compressed Gas Liquid (CGL™) technology to lower energy costs in various markets, generating new opportunities for economic growth and environmental stewardship. The CGL technology optimizes the blending of natural gas and NGL into a single liquid product cargo.

Gas Processing & LNG recently talked with Bruce Hall, President and Chief Operating Officer of SeaOne Holdings LLC, about the company’s CGL technology, its value proposition against LNG and its current projects.

GP: Can you share some background on SeaOne and how its patented CGL technology works?

BH: SeaOne was founded in August 2004 by a small team including CEO Forrest Hoglund, Bart Baker and me. Forrest previously served as the founder and first Chairman and CEO of EOG Resources Inc., and I had been with British Gas Corp. and Total. In late 2003, I was asked by Forrest to look at an offshore gas monetization application and to determine what technology would best work for the application. The only options at the time were pipelines, CNG, GTL and FLNG, which was in its infancy.

The fundamentals and science behind my development of Compressed Gas Liquid (CGL) is predicated on gas physics, which was well known. The CGL process we developed optimizes the blending of natural gas and NGL into a single delivery of a non-cryogenic liquid cargo by manipulating the gas physics (i.e., optimizing the temperature and pressure of the mixture). The CGL technology is a proprietary and patented, non-cryogenic gas solvation technology that we control. With CGL, we have created an efficient and economic delivery system that solvates the natural gas and NGL supply chains into one. The CGL system design uses standard, proven, non-cryogenic gas plant designs, offering both reduced capital cost to SeaOne and natural gas and product delivery benefits for our customers.

GP: For which gas delivery scenarios is the application of SeaOne’s technology optimal?

BH: In the early development of SeaOne’s business model, we focused on natural gas and NGL field-to-market delivery. Since that time, SeaOne’s business model has successfully evolved to where it is today. We leverage CGL’s low-cost advantage to develop integrated logistics and power infrastructure to serve energy-isolated countries in the Caribbean Basin and Central and South America. These regions have been unable to reliably and economically source clean fuels, leading to commodity shortages and inefficient, expensive, environmentally disadvantaged power generation.

SeaOne’s business model utilizes a tolling arrangement structure and essentially builds a pipeline connecting these disadvantaged regional markets with direct access to the abundant and efficient U.S. natural gas and NGL markets, through a single supply chain. We believe that the cost profile and the development of a fully integrated CGL project, together with access to low-cost, U.S.-sourced gas and the ability to serve NGL markets, will allow CGL to emerge as the preferred, single gas-delivery solution in South America, the Caribbean and beyond.

GP: How does SeaOne see its technology being applied in the creation of a complete energy value chain?

BH: By consolidating multiple production, storage and logistics businesses, SeaOne’s business model is fully integrated and requires significantly less investment and lower operating expenses than existing conventional natural gas and NGL delivery technologies. The resulting cost savings allow us to provide a complete energy value chain, including power generation, bulk storage of fuels and delivery of specified fuel blends.

Most of the customers we work with need cleaner fuels and new power generation and infrastructure to support this, which will provide socio-economic benefits. Our business solution provides the entire package. Our port, fuels storage and power projects in Buenaventura, Colombia are a great example of this.

GP: Your CGL technology reduces investment and operating expenses vs. conventional natural gas and NGL delivery systems. Is the technology also competitive against LNG?

BH: It is competitive against LNG as a delivery method for methane, and distinct in significant ways. The gas composition stream of LNG consists mainly of methane (C1), which has a higher heating value (HHV) in the range of 950 Btu/sft3–1,200 Btu/sft3. CGL, in contrast, consists of the full gas stream (C1 through C6+) and has an HHV in the range of 1,280 Btu/sft3–2,800 Btu/sft3, but can deliver to market at any fuel specification.

Our process is much simpler and easily scalable, utilizing standard, non-cryogenic gas plant systems and processes, and a significantly smaller land and carbon footprint. As a result, we require 50% less capital and operating costs for our production and export facilities than would a greenfield LNG liquefaction project of equivalent export capacity. We also boast significant environmental gains. LNG’s cooling process (the process to liquefy methane) requires two-thirds more electricity than does the CGL process for the same production volume. As a result, LNG has 60% more emissions than CGL because LNG’s process requires three stages of cooling and the CGL solvation process requires only one.

We are distinctly different from LNG in both process and what is ultimately delivered to the customer. CGL adds value due to its ability to deliver to market HHV fuels and products (C1 through C6+). This has proven to be highly beneficial to our customers in the Caribbean and Colombia. The cost of converting power plant generators to use HHV fuel blends available from the CGL receiving terminals is lower vs. what they would pay to run solely on the methane contained in LNG, LPG or diesel.

GP: Can you share details on your project under development in Colombia? What do you hope will be learned from this project that can be applied to future developments?

BH: SeaOne’s gas-to-power value chain is anchored by a multi-use energy port development located on the Pacific coast of Colombia, in Buenaventura. Our development is known as the Puerto Solo Complex. In early 2019, SeaOne purchased the Puerto Solo Energy Port Concession in the Port of Buenaventura, Colombia. Due to the size of the project and the in-service dates for the project, we have broken it into two phases.

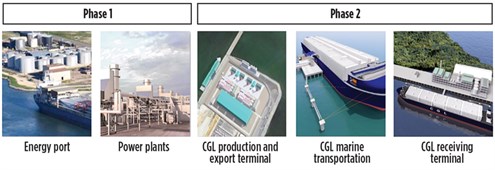

Phase 1 development of the port and two power projects are underway, and the current scheduled in-service date is late 2021. We have been awarded firm energy obligations for the construction of two new power plants totaling 228 MW. Phase 1 of the Puerto Solo Complex will deliver immediately needed power generation, 100,000 bbl of LPG, and 320,000 bbl of finished products via our import infrastructure. The addition of the 400-MMsft3d CGL infrastructure and delivery pipelines in Phase 2 will include our U.S. production and export terminal, the Puerto Solo CGL receiving terminal, and maritime assets to deliver natural gas and NGL to end markets (FIG. 1).

|

|

FIG. 1. Planned Phases 1 and 2 of the Puerto Solo Complex in Buenaventura, Colombia. |

I think one of the many lessons we have learned from this project that can be applied to future developments is that it is important to bring multiple solutions. We may have set out to just deliver fuel, but we are now solving much bigger issues like meeting critical power needs and fuels with our infrastructure, which results in significant socio-economic and environmental benefits to the region. We have found that we can and want to serve a greater purpose than what we originally set out to accomplish.

GP: Can you tell us more about the gas delivery solutions SeaOne is studying for power infrastructure elsewhere in the world?

BH: Beyond Colombia, we remain focused on the Dominican Republic, Belize, Puerto Rico and Mexico to provide end-to-end solutions for cheaper electricity and the reduction of carbon emissions resulting from the displacement of existing fuels, such as diesel, heavy fuel oil and coal. Electricity in these areas is among the most expensive in the world. Access to lower-cost, cleaner fuels from the U.S. has not previously been feasible. SeaOne’s CGL technology and business model are able to offer substantial reductions in both fuel costs and carbon emissions.

We are investigating other opportunities in Nigeria, Brazil, Indonesia, Central America and Europe. Some of these projects involve a power component, and others are purely about providing a more economical alternative to LNG for getting a customer’s stranded gas to market.

GP: Is SeaOne studying additional technology applications for the midstream sector?

BH: Over the years, SeaOne has looked at various applications, including small-scale natural gas and NGL packages for location at the well site; improving gas recovery from offshore sour gas wells; small packages for lower-cost fuel for integrated barges on the Danube; and railway locomotive fuel conversions, to name a few. I am sure, going forward, we will find even more applications. GP

|

Dr. Bruce Hall serves as a Member of the Board of Managers and President and Chief Operating Officer of SeaOne Holdings LLC. He is the primary inventor of the company’s Compressed Gas Liquid (CGL™) technology and resulting patents, and oversees all of SeaOne’s business operations in the U.S. and abroad.

Dr. Hall has more than 40 yr of experience in the oil and gas and petrochemical industries. He served as Vice President of Arctic Resources Co. and as Managing Director for ArctiGas Resources Corp. (Canada). Previously, Dr. Hall worked with British Gas Corp. as the Head of Planning and Development where, among other areas of responsibility, he led the development of the company’s early interest in Atlantic LNG in Trinidad and Tobago. He also worked for Total SA as the Head of Planning and Development, and led the company’s involvement in the early development of Yemen LNG.

Dr. Hall holds a PhD in mechanical engineering from the University of Texas at Austin; an MBA degree from the University of Toronto in Ontario, Canada; an MS degree in mechanical engineering from the University of California, Berkley; and a BSc degree in electrical engineering from the University of Witwatersrand in Johannesburg, South Africa.

Comments