New in Gas Processing Technology

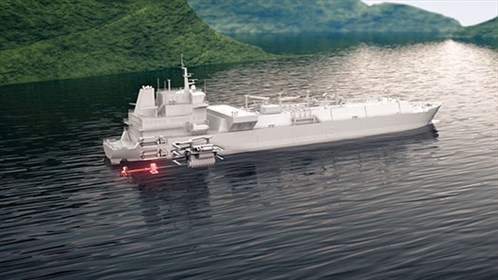

ABB releases new shaft generator technology

|

The generator allows easy and flexible installation to bulk carriers, container carriers and LNG tankers.

The AMZ 1400 permanent magnet shaft generator is optimized for converter control and enables better efficiency than either induction or electrically excited synchronous machines

at both full and partial loading. This helps to cut fuel costs and significantly reduce CO2 emissions.

Its compact size shrinks the footprint of the equipment package by around 20% compared to a conventional synchronous or induction-type shaft generator. In addition, the weight is reduced by approximately 30%. The unit is also simpler to install at the shipyard, as the intermediate propulsion shaft is mounted to the generator and then lifted into the vessel for alignment.

Servomex delivers oxygen analyzer to PTA facility

|

The SERVOTOUGH OxyExact 2200 is a high-specification oxygen analyzer that monitors process applications such as feedstock purity testing. In addition, it cleans up hydrogen (H2) and chlorine production, solvent recovery and oxidation control processes, ethylene oxide and ethylene dichloride production.Servomex has delivered its SERVOTOUGH OxyExact 2200 to INEOS Aromatics for a $70-MM upgrade project at its facilities in Indonesia. In addition, Servomex installed two vent gas analyzer systems. The project is aimed at reducing emissions and increasing capacity.

The technology uses a three-enclosure system that facilitates the sampling and measuring of any flammable gas for 0%–100% oxygen, with no need for pre-sample drying. Up to six analyzers can be connected to a single control unit.

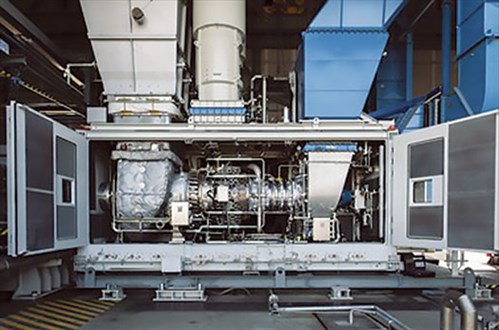

Baker Hughes to provide hydrogen-ready turbo-compression technology for pipeline

|

Baker Hughes has won a contract from TERNA to supply gas turbines and compressors able to run on a blend of natural gas and hydrogen (H2) for a new compression station of the Greek Natural Gas Transmission System. The compression station will serve the domestic gas supply in Greece.

Baker Hughes will provide three compression trains for three NovaLT12 H2-ready gas turbines and three pipeline compressors. The technology has been designed to support the compression station with the capability to transport up to 10% H2. The station is expected to enter operation in 2024 and directly supports the EU’s H2 strategy goals to accelerate the development of clean H2 and ensure its role as a cornerstone of a climate-neutral energy system by 2050.

Tellurian’s Driftwood LNG begins construction

Tellurian has begun Phase 1 of the Driftwood LNG terminal, an LNG export facility located in Louisiana, U.S., that will have an approximate liquefaction export capability of 27.6 MMtpy.

Once the demolition, civil site preparation and construction of critical foundations are completed, Baker Hughes will manufacture two of the natural gas turbines required to complete Phase 1.

Phase 1 will include two LNG plants with export capacity of 11 MMtpy. Driftwood has obtained all significant permits needed for construction and operation, progressed detailed engineering to about 30% completion and finalized the purchase and lease of approximately 1,200 acres of land.

Drager releases gas detection technology

Drager’s X-pid 9500 combines two measuring modes to detect volatile organic substances, such as benzene, at extremely low temperatures in as little as 30 sec. The product is an upgraded version of the X-pid 8500, released in 2017.

The X-pid 9500 includes a search measuring mode, enabling continuous monitoring for PID-sensitive compounds. The user can then utilize the analysis mode for a more in-depth examination.

More than 40 target substances can be measured, including hexane, isobutylene and xylene. Additional substances to target can be added to the database by performing a local qualification, using a known concentration of the target compound.

The search mode uses broadband measuring to determine the total concentration of detectable volatile hydrocarbons in the ambient air. A smartphone can control the gas detection unit with a downloadable application, which also evaluates the measurement data.

LNG Canada receives first mega-module

Canada has received its first significant facility module at the LNG Canada site in Kitimat, B.C.

The 35-m, 4,618-metric t module will be the entry point for natural gas delivered to the LNG Canada site via the new Coastal GasLink pipeline. This module follows several other large pieces of LNG infrastructure recently installed at the site.

Burckhardt Compression, PTC collaborate to develop remote service solutions

Burckhardt Compression is working with PTC to develop remote service solutions for its customers. In addition, the companies are working together to continue developing a type of metaverse augmented reality (AR) solution for service on reciprocating compressors.

Under the name UP! Solutions, Burckhardt Compression offers digital solutions that enable compressors to be monitored in real time and serviced remotely in cooperation with the customer onsite. For this purpose, the units are equipped with sensors that constantly collect data, such as vibrations and temperature, which are then analyzed and used to detect anomalies or schedule service work.

Burckhardt Compression relies heavily on Vuforia, the AR solution from PTC, which observes an expert during a process, compiles instructions for teaching and guiding less-experienced colleagues and then monitors the learning phase.

RINA approves the first hydrogen-powered MR tanker

|

RINA has received approval in principle for Swedish designer FKAB Marine Design’s hydrogen- (H2-) powered MR tanker. The propulsion is based on combining the ship’s fuel source, LNG, with steam in a gas reformer to separate LNG molecules into H2 and carbon dioxide (CO2).

The H2 is then directly utilized to fuel the internal combustion engines and fuel cells. In theory, the ship can meet total decarbonization targets by either running entirely on H2 or producing all the required power by fuel cells.

Veolia, DuPont convert utility infrastructure

Veolia and DuPont have converted the DuPont Spruance manufacturing facility in Virginia, U.S., from coal to natural gas to efficiently produce steam and electricity. The facility will assist with optimizing energy yields while achieving a GHG emissions reduction of > 220,000 tpy.

According to project terms, Veolia was to acquire, upgrade, operate and maintain the site’s utility infrastructure to improve efficiencies and reliability. The agreement included repurposing a 200-MW cogeneration facility from power production to the production of 500,000 lb/hr of steam, converting from coal to natural gas, and upgrading chilled water capacity, water networks and compressors.

Cynalytica delivers the first deployment of SerialGuard cybersecurity solution for gas pipeline operations

|

Cynalytica’s SerialGuard is an entirely passive serial packet sniffer that allows secure visibility within vulnerable legacy networks designed for industrial control systems (ICSs). Legacy serial communications account for 30%–60% of all critical U.S. infrastructure.

Many ICS security providers only monitor TCP/IP and Ethernet communications, leaving a significant blind spot for gas pipelines. The SerialGuard sensor monitors Level 1 and Level 0 serial communications between field devices and controllers.

Wärtsilä to deliver the first dedicated methanol fuel supply system

|

Wärtsilä has developed MethanolPac, a fuel supply system specifically for methanol. In conjunction with the newly released Wärtsilä 32 methanol engine, the company can deliver methanol-capable fuel and power systems across a wide range of vessel segments. When methanol is produced from renewable sources, it is carbon neutral and easier to manage than many other fuels. However, industry experience integrating methanol is scarce due to the lack of vessels operating on the fuel.

MethanolPac includes both low- and high-pressure parts of the fuel supply system as well as the related control and safety functions, including the high-pressure methanol fuel pump unit, low-pressure pump module, fuel valve train, bunkering stations and tank instrumentation.

The Wärtsilä 32 methanol engine combines long-established methanol fuel injection technology with control and automation systems. In addition, methanol fuel injection can be retrofitted to any of the Wärtsilä engines in operation. Wärtsilä plans to develop an ammonia-fueled engine concept by 2023 and a hydrogen concept by 2025.

TanQuid, Implico complete digitalization of Duisburg terminal

TanQuid and Implico have completed the digitalization project at the Duisburg tank terminal utilizing Implico’s OpenTAS 6.0. The new IT landscape offers automated workflows, expanded service offerings, comprehensive data collection and evaluation, and paperless processes.

The OpenTAS 6.0 automizes all major operations at a facility. It connects with the enterprise resource planning system, gathers data and produces key performance indicators (KPIs). The technology can also be combined with a variety of modules to adapt to the facility’s needs.

Aemetis completes testing of biogas-to-RNG upgrading facility

Aemetis has finished testing the $12-MM dairy biogas-to-RNG upgrading and compression facility for the Aemetis Biogas Dairy Digester project. The unit is located at the Aemetis Advanced Fuels Keyes ethanol plant near Modesto, California, adjacent to the utility natural gas pipeline.

The full system mechanical commissioning process for the facility has been completed. Pacific Gas & Electric (PG&E) is now conducting final tests of the utility gas pipeline interconnection unit, which will allow the injection of utility-grade renewable natural gas into the PG&E gas pipeline.

When completed, the facility is expected to capture more than 1.6 MMBtu of dairy methane and reduce GHG emissions equivalent to an estimated 5 MM metric tpy of CO2.

GTT, Deltamarin receive an AiP from DNV for a new LNG-fueled PCTC design

GTT and Deltamarin have been awarded an Approval in Principle (AiP) from the Norwegian classification society, DNV, for an innovative LNG-fueled pure car and truck carrier (PCTC) design.

GTT and Deltamarin have been cooperating to develop a new dual-fuel PCTC design that is able to carry 8,000 car equivalent units. This design introduces a new generation of PCTCs, incorporating GTT’s Mark III membrane LNG fuel tank and Deltamarin’s expertise in developing state-of-the-art vessels.

The AiP from DNV confirms that the design of the LNG-fueled PCTC is feasible and that no obstacles exist to prevent the concept from being constructed and operated. The 2-barg design pressure of the LNG fuel tank enables improved pressure holding capabilities and increased operational flexibility, especially during bunkering operations. GP

Comments