Case study: Optimization of LPG process at Ju’aymah NGL fractionation plant

Optimization initiatives for the LPG Merox process were implemented to reduce operating cost and spent caustic generation at Saudi Aramco’s Ju’aymah NGL fractionation plant. These initiatives included an increase in fresh caustic concentration and reuse of extractor spent caustic in the Merox process.

Also, a new catalyst was successfully used in the Merox system, with higher activity than a conventional catalyst. Benefits were derived from the new catalyst with regard to consumption rate, fresh caustic use and spent caustic generation.

The implementation of these initiatives contributed significantly to enhanced treatment efficiency, with a lower operating cost of $0.5 MM/yr, both from fresh catalyst and disposal of spent caustic. Spent caustic generation from the LPG Merox process was reduced by approximately 50%.

Process background. The Ju’aymah NGL fractionation plant has four identical fractionation trains. Each train consists of deethanizer, depropanizer and debutanizer columns; an amine treating facility to remove hydrogen sulfide (H2S) and carbonyl sulfide (COS) from C3 product received from the depropanizer overhead, and Merox processing units for mercaptan sulfur removal from C3 and C4 products, followed by the C3 and C4 dehydration system for moisture removal from the final product.

An opportunity was identified for the optimization of the LPG Merox process to reduce spent caustic regeneration, product sulfur and catalyst consumption, and therefore reduce plant operating cost. This article describes the initiatives implemented to optimize the Merox process and achieve these benefits.

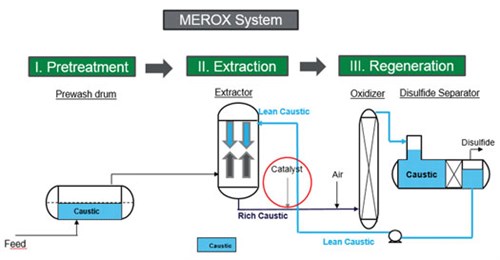

Merox process overview. The Merox process consists of three sections, as shown in FIG. 1. The first section consists of prewash drums to remove H2S and COS left over from the amine unit. Separate prewash drums are in place for both C3 and C4 products. Followed by prewash drums, the second section is the extractor, which contains C3 and C4 mercaptan extractors, and the last section is the combined Merox regeneration for the regeneration of mercaptan-rich caustic collected from both of the extractors.

|

| FIG. 1. Merox process overview. |

The prewash drums are operated at a caustic concentration of 5 wt%–10 wt%, while the extractors are operated at a caustic concentration of 8 wt%–12 wt%. In extractors, mercaptan reacts with caustic and forms sodium mercaptide (Eq. 1), which is oxidized in the regeneration section for conversion back to caustic and disulfide oil (Eq. 2).

RSH + NaOH → NaSR + H2O (1)

NaSR + ¼ O2 + ½ H2O → NaOH + ½ RSSR (2)

The overall Merox process reaction can be written as shown in Eq. 3:

RSH + ¼ O2 → ½ RSSR + ½ H2O (3)

In the Merox process, intermittent liquid Merox catalyst is injected into the rich caustic before the oxidizer. In the oxidizer, mercaptide is oxidized to disulfide oil and caustic, which are separated in the disulfide separator drum. In the overall Merox process, the caustic and Merox catalyst concentration is reduced with time due to the dilution effect.

To maintain optimum concentration, partial caustic replacement is carried out every couple of days. Due to a high system volume, this generates a large quantity of spent caustic from the Ju’aymah NGL facility every year. Shipment of the spent caustic is a costly measure and has a significant impact on plant net direct expenditure.

Process challenges and optimization opportunity. In addition to high spent caustic generation, other Merox process challenges included frequent system troubleshooting to control the product sulfur, high Merox catalyst consumption rate and high catalyst expense.

An opportunity was identified for the optimization of the Merox process to reduce product sulfur, spent caustic regeneration and catalyst consumption and, therefore, reduce plant operating cost. The plant engineering team generated several in-house initiatives to optimize the process, several of which were successfully completed:

- New catalyst deployment in the Merox system

- Increase of fresh caustic concentration from 25 Baume (°Be) to 35°Be

- Reuse of extractor spent caustic in prewash drums

- Development of new training and awareness sessions for personnel

- Implementation of an online monitoring dashboard.

Each of these initiatives are described in detail in the following sections.

New catalyst deployment. To promote the oxidation reaction in the Merox regeneration section, liquid Merox catalyst is added intermittently. Catalyst is initially loaded after the unit shutdown for testing and inspection, with fresh caustic at an approximate concentration of 200 ppm. This catalyst is diluted with time after every caustic dumping; consequently, makeup catalyst is added to maintain the optimum concentration.

In 2018, plant personnel deployed a new catalyst to enhance the Merox system’s overall performance. Initially, a pre-pilot test assessment was completed with Saudi Aramco Central Engineering Department’s Process and Control Systems Department. The test ran the new catalyst in Modules 1 and 2, with fresh caustic, after testing and inspection. A pilot test was carried out for 6 months, and the Merox system operating parameters, including the product sulfur and catalyst consumption, were monitored.

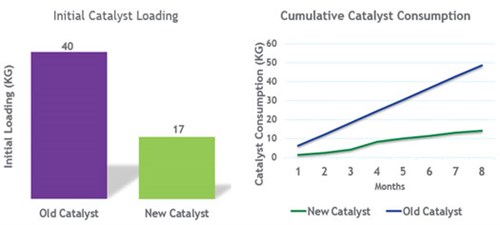

The overall experience with the new catalyst was very good, and its activity was found to be significantly higher than the conventional catalyst, as confirmed by the catalyst consumption pattern. Due to this higher activity, the catalyst consumption rate was reduced significantly. Initial catalyst loading was approximately 50% lower compared to the old catalyst, and the cumulative catalyst consumption rate was reduced by more than 50% in normal operation (FIG. 2). Product sulfur was reduced by 6 ppm, compared with the old catalyst (FIG. 3).

|

| FIG. 2. Catalyst consumption rate. |

|

| FIG. 3. Product sulfur before and after new catalyst use. |

With the use of the new catalyst, spent caustic generation was reduced by approximately 20% due to the efficient regeneration of mercaptide in the Merox regeneration section; fresh caustic consumption was also reduced by the same rate. The subject catalyst per unit price was also significantly lower than the conventional catalyst. The use of the new catalyst significantly reduced the overall operating cost. Additionally, since the use of catalyst methodology and procedures were the same as for the old catalyst, no additional process modification or training for plant operators were required.

Increasing fresh caustic concentration. The next Merox process optimization initiative increased the fresh caustic concentration from 25°Be to 35°Be.

As described in the previous section, the caustic concentration comes down with time due to the dilution effect in the Merox process during normal operation; therefore, partial caustic is dumped from the system and refreshed with fresh caustic. From startup, the plant’s normal practice was to import the fresh makeup caustic as a concentration of 25°Be, which is approximately 19 wt%.

Approximately 20% of the total caustic from the system with a 10 wt% concentration is replaced with fresh caustic at 19 wt% concentration; therefore, the caustic concentration was increased from 10 wt% to 11.8 wt%. In normal operation, this concentration would last for approximately 4 weeks before the next caustic dumping was required.

One process improvement was implemented to address the caustic concentration. By increasing the concentration from 25°Be to 35°Be, which is 19 wt% to 29 wt%, the concentration in the system was increased by approximately 1.8 wt%, compared with the 25°Be fresh caustic use. Increasing the caustic concentration in the system lasted longer than it had previously; therefore, the caustic dumping frequency was reduced by around 20%. The total caustic dumping volume was also reduced by 20% in 1 yr, which positively impacted plant operating cost.

Extractor spent caustic reuse in prewash drums. As explained in the Merox process overview section, the prewash drums operate with a caustic concentration limit of 5 wt%–10 wt%, with 30%–50% of liquid level to avoid spent caustic carryover into the extractor. The objective of this lower concentration of caustic in the pretreatment area is to remove the remaining H2S and COS from the feed before entering the extractors.

The caustic in the prewash is not regenerated and is spent with time, where caustic molecules would be no longer free to react with the remaining H2S in the feed. When the concentration reaches lower than 5 wt%, it is completely removed from the system and refreshed with fresh 10 wt% caustic.

Plant personnel realized that the extractor spent caustic, after being reduced to lower than 8 wt% concentration, was still suitable for prewash drum use. The plant operations team began practicing the transfer of spent caustic in the extractors to the prewash drums for full reuse. This initiative reduced spent caustic generation by a significant amount.

Additional training and online monitoring. The last initiative involved the use of awareness programs, additional training and the implementation of an online monitoring dashboard.

The plant engineering team realized the need for greater awareness among young engineers and operators, as well as more training to operate the Merox system efficiently. Caustic dumping and refreshing were considered preferred practices to control product sulfur; therefore, a learning environment was created to troubleshoot the Merox process and provide more in-house training and workshops to the operators and engineers.

An operator handbook, Sulfur Troubleshooting Guide, was published with simplified system troubleshooting charts. Additionally, an online troubleshooting dashboard in the plant information and distributed control systems was developed to be accessible to engineers and operators for critical parameters for online monitoring, as well as comparison with standard operating range parameters, for easy identification and correction of out-of-range parameters.

In addition to the Merox system, the amine system was included in this dashboard. Amine system parameter monitoring is equally important to avoid H2S and COS carryover into the Merox system. This initiative significantly helped reduce product sulfur without frequent caustic dumping from the system.

Takeaway. The successful implementation of several initiatives to optimize the LPG Merox process contributed significantly to the enhancement of Merox treating efficiency by reducing operating cost by more than $0.5 MM/yr, both from the use of fresh catalyst and the disposal of spent caustic.

Additionally, these initiatives reduced spent caustic generation from the LPG Merox process by approximately 50%. All of the projects were implemented without process modification or CAPEX by the company. GP

|

PUKHRAG GARG has served as a Lead Process Engineer with Saudi Aramco’s Ju’aymah NGL fractionation plant since 2012. He is a certified Professional Engineer with more than 17 yr of experience in the oil and gas industry. He previously worked with Reliance Industries, UOP and DuPont as a Process Engineer. Mr. Pukhraj holds BS and MS degrees in chemical engineering from the Indian Institute of Technology (IIT) in Bombay and Mumbai, India, as well as an Executive Post Graduate Diploma in capital and finance from the Indian Institute of Foreign Trade (IIFT) in New Delhi, India.

|

UTHMAM A. AL-DAHLOUS is an Engineering Superintendent at Saudi Aramco’s Ju’aymah NGL fractionation plant. He has more than 24 yr of experience in NGL fractionation and petroleum refining. Mr. Al-Dahlous holds a BS degree in chemical engineering from King Fahad University in Saudi Arabia.

Comments