Streamline the LNG FERC application process

In the U.S., the Federal Energy Regulatory Commission (FERC), along with several other federal, state and local agencies, governs review and approval for construction and operation of LNG facilities. Other nations have similar regulatory reviews. LNG FERC applications are lengthy and exacting. The permit application process can face numerous challenges and potential delays, with a consequent reduction in the project’s economic viability. This article presents strategic considerations for streamlined management of LNG FERC applications.

LNG processes and hazards. LNG has been widely recognized as an important intermediate step to transition to clean energy from fossil fuels. Experts recognize that this transition should be carefully calibrated as a gradual process. Relative to many other fuels, LNG contributes significantly lower greenhouse gas emissions and pollutants.

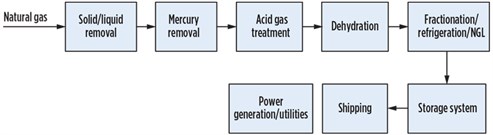

A number of mature LNG technologies are available on the market from leading companies. Although these technologies differ in their routes for producing LNG from natural gas, some of the common building blocks are feed conditioning (e.g., liquid/solid removal from incoming stream, mercury removal, acid gas removal), dehydration, liquefaction, refrigeration, fractionation, storage and utility infrastructure.

LNG projects are multibillion-dollar projects. Technology selection requires a comprehensive assessment of myriad factors including, for example, location, safety/environmental impact, public acceptance and regulatory review process, global economic and political events, and finally return on investment (ROI). FiG. 1 shows a process flow scheme for an LNG facility.

|

| FIG. 1. LNG facility process flow scheme. |

Since flammable chemicals (i.e., condensate, refrigerants and LNG itself) form a major segment of the chemicals in an LNG plant, flammability hazards exist. For example, pool fire from spills, jet fire from high-pressure release of flammables, BLEVE (boiling liquid expanding vapor explosion) and radiation are some of the principal flammability hazards. In addition, chemicals including ammonia, mercury and nitrogen present exposure hazards, including asphyxiation and long-term health effects.

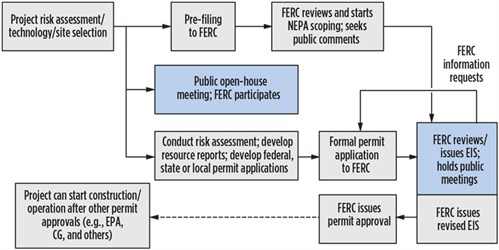

FERC application process. FERC is the lead agency that reviews/approves site selection, design, and construction of LNG facilities in the U.S. and nearshore installations. FERC also oversees operation of LNG facilities throughout their lifecycle. Depending on the location of the LNG facility, other agencies may participate in LNG application review. These agencies include the Department of Transportation (DOT), the Pipeline Hazardous Material Safety Administration (PHMSA), the U.S. Coast Guard, the Environmental Protection Agency, the Federal Aviation Administration, the Fish and Wildlife Service, the Forest Service, the Bureau of Land Management, and state and local agencies.

As shown in FIG. 2, the FERC process is open and transparent to the public. Briefly put, the LNG applicant company or project sponsors survey the market projections, and if they are deemed economically attractive, then they invest in the project. Site surveys are carried out, and potential/alternate sites are selected based on numerous criteria including infrastructure near the site, seismic analyses, and regulatory and public support. The site survey is followed by the following steps:

|

| FIG. 2. Strategic view of the LNG FERC application process. |

- Pre-filing to FERC

- Continue assessment of safety, environmental and other risk factors, including those required by the National Environmental Policy Act (NEPA); as the project progresses, risk assessment will become more granular

- Hold open-house meetings with neighbors (FERC can attend these meetings)

- Develop resource reports per FERC guidelines and submit formal FERC permit application

- FERC reviews application and may ask for clarification

- FERC develops a preliminary environmental impact statement (EIS) based on NEPA guidelines and holds public meetings to discuss the EIS

- FERC issues revised EIS, after public input is incorporated

- FERC approves permit, and the company can start construction and operation after receiving other approvals, including those from state and local agencies.

Strategic considerations in LNG FERC permit applications. A crucial element in the LNG FERC process is communication with stakeholders. Poor or inadequate communication could scuttle the project. Stakeholders include regulatory agencies, residents, elected officials, tribal leaders, news media, landowners and business leaders. Communication with stakeholders requires diplomacy and technical competence. The following principles can be accepted as guidelines for communicating with stakeholders:

- Identify stakeholders and establish a system for communications. Establish a single point of contact to avoid potential confusion.

- Focus on providing accurate and fact-based information quickly. Hold open-house meetings. Make note of stakeholder concerns, and explain the safeguards being taken to minimize risk. Respond promptly to stakeholder requests for information.

- In dealing with the public, demonstrate cooperation, empathy and diplomacy. Public communications require technical skill, as well as marketing and communication skills.

- Use the NEPA framework to identify a broad range of risks to neighbors including safety, environmental, societal and economic risks.

- As the project progresses, risk assessments will become more granular. Establish a system for ensuring traceability of documents.

Project communications. More often than not, LNG projects entail multiple contractors and subcontractors and myriad communication and database management systems. For instance, dispersion and fire risk analyses may be performed by a contractor. Other contractors may perform fire protection risk assessment and fire protection design. Yet another contractor may provide process engineering and flare system analysis. On many projects, these contractors are spread over multiple continents. Several key issues should be considered to ensure smooth communications among project contractors:

- A contractor’s economic robustness is an important quality. In the event of closure or acquisition of a contractor, it is possible that data and reports generated for the project might become difficult to access due to poor management during the closure or acquisition process. This possibility must be carefully weighed in the contractor/subcontractor selection process.

- Diverse database management systems of contractors should not result in communication headaches. Ensure that proper interface systems are in place.

- Ensure that a contractor puts experienced engineers and other professionals on the project. Do not let a multibillion-dollar LNG project become a training ground for ill-prepared professionals.

- As stated earlier, contractors spread over multiple continents is now the norm, rather than the exception. This arrangement has been used with remarkable success over the years. Ensure that language differences, cultural variations and diverse communication systems are considered from the start. Ensure that adequate IT support is available to avoid communication delays.

Document infrastructure. Documents should be quickly available and traceable. As a corollary to this, documents should be clear, consistent and complete. FERC comprehensive guidance documents for preparing environmental reports, Guidance Manual for Environmental Report Preparation, Vol. 2,1 provides detailed guidance for developing resource reports. Ensure that all documents are in compliance with the detailed requirements of this guidance manual. Consider the following:

- In terms of risk abatement and management, the hierarchy of risk management to be followed is risk elimination, risk management/mitigation through protective layers, and training and procedural safeguards.

- Ensure that a hazard analysis involving flammable and toxic vapor dispersion, overpressure analysis and thermal radiation analysis have been performed by FERC-approved or equivalent software. The hazard analysis should consider all plausible scenarios of loss of containment and should show affected envelopes or areas. All assumptions should be clearly stated. The results should show that vapor clouds (one-half of lower flammability limit boundaries), overpressure and radiation estimates comply with NFPA-59A requirements.

- Similarly, fire risk assessments should consider each process segment in detail and provide a means of passive and active fire protection. All assumptions should be clearly stated.

- Although it is common knowledge that documents should be clear, complete and consistent, massive volumes of documents sometimes result in inadequacies. Examples of inadequacies are:

- Drawings and their PDF versions are hard to read. Often, this is a result of drawings that are too dense. Before submitting to FERC, check if the drawings can be read with visual clarity.

- Drawings are incomplete—e.g., comments are numbered on the drawing, but the comment text is not included.

- Inconsistency among documents—e.g., a drawing shows an impoundment basin as size 60 ft × 60 ft × 4 ft, while a related risk document lists different dimensions for the same basin.

- Fire risk assessment lacks explanations on the basis of fire water (flow and pressure) calculations.

Although these inadequacies are relatively easy to rectify on an individual basis, collectively, they may cause significant delays in the FERC review/approval process. These inadequacies could also severely impair communication with the public and jeopardize the project’s credibility.

- For projects that are augmentations of projects that have been approved, it is natural to state: “Refer to Project 01.” Although this seems like a rational approach, if it leads to delays at FERC in finding relevant documents from the earlier project, FERC may come back with requests for clarification and more reports. Where appropriate, provide documentation that will minimize the need for cross-referencing.

Cradle-to-grave management. The term “cradle-to-grave management” is commonly used in waste management operations. It is based on a systems approach to managing risk. This approach applies to the LNG FERC application process, as well. Key points to consider include:

- Communication channels to stakeholders will need to be open from the permit application stage through construction, operation and final closure of the facility.

- Ensure that systems are in place for risk management during the construction, operation and closure phases of the project.

- Provide for periodic training.

- Ensure continual, robust maintenance of equipment, instruments and safety-critical systems.

To summarize, the LNG FERC process is detail-oriented and requires a considerable degree of planning. Industry experts have observed that the LNG industry, as a whole, has shown impressive safety performance. The key to maintaining this record is superior risk management throughout the life of every LNG project. GP

LITERATURE CITED

- FERC, Guidance Manual for Environmental Report Preparation, Vol. 2, LNG Project Resource Reports No. 11 and No. 13, February 2017.

|

G. C. SHAH is a Senior Consultant involved in process/occupational safety and plant troubleshooting for LNG, refining and petrochemicals. His 30 yr of experience includes plant operations, as well as consulting. He has published more than 80 articles in industry publications.

Comments