New in Gas Processing Technology

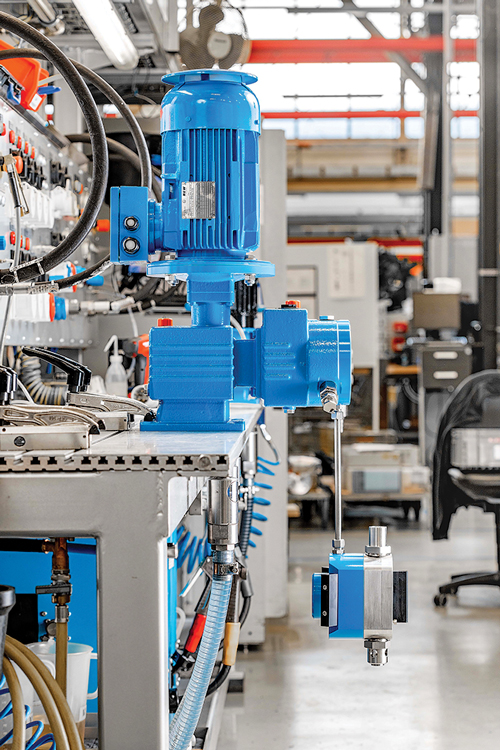

Avoid heat input into the gas vessel with a diaphragm metering pump

|

Before biomethane can be supplied to private and industrial customers, its calorific value must first be adapted to the natural gas network. The Prolimix mixer system from Scharr Tec GmbH & Co. KG can inject propane through several nozzles in liquid form and without energy-intensive evaporation.

Scharr Tec developed a concept that has now been successfully implemented in the industry for several years. Ecoflow diaphragm metering pumps from LEWA GmbH are mounted as a remote solution. These custom-made products from the Leonberg pump experts make it possible to avoid the problem of heat input, despite the increase in pressure caused by a driving head installed in the manhole shaft.

At the same time, the pump is precisely matched to the required flowrate, so that there is neither backflow into the tank nor any power loss. Since the pump is designed for 40-bar operating pressure, biomethane conditioning can also be carried out for long-distance networks.

Portable dewpoint analyzer for natural gas quality

|

Michell Instruments’ CDP301 hydrocarbon and water dewpoint tester is a fully portable, manual-visual dewpoint instrument that uses the chilled mirror technique for accurate measurements of both hydrocarbon and water dewpoint. It is ATEX, IECEx and cQPSus compliant for use in a Zone 1 or 2 Hazardous Area and Class I, Division 1 Hazardous Locations, allowing it to be positioned close to the process sample test point. Since it is fully self-contained, there is no need to use a separate coolant gas.

The CDP301 includes a full-color interface that shows a magnified view of the mirror surface. Red-spectrum laser light illuminates fine water droplets and ice crystals when targeting water dewpoint. Broader-spectrum white light enables the iridescent film synonymous with hydrocarbon condensate to be detected with a high sensitivity of up to 5 mg/Nm3.

The temperature, pressure and dewpoint can be recorded at the push of a button. The video footage and/or still images, along with corresponding data, for multiple measurement cycles is logged for later review either on the instrument’s display or on a PC. The dewpoint tester also meets ASTM D1142 and ISO6327 requirements. GP

Comments