Opportunities for increasing efficiency in small- to mid-scale LNG plants—Part 1

R. Galavotti, Consulting Engineer, Milan, Italy

A few factors are incentivizing lifecycle cost (LCC)-focused production capacity for mid-scale LNG in a different technological context. These factors include the dramatic increase in cost experienced for projects after 2008, the risks of investments related to market uncertainties, the debut of floating LNG (FLNG) and the possibility to access open-art technologies for LNG liquefaction. Small-scale LNG plants (i.e., those with capacities of less than 1 metric MMtpy) can minimize the investment required by reducing capacity, thereby reducing risks for investors. However, efficiency is a significant driver in design when plants are based on a tolling model.

This article assesses opportunities in small- and mid-scale LNG plant design. The consistent selection of cooling medium, compressor drivers and power generation can bring value to such projects, particularly FLNG and brownfield plants. Reducing annual production, exporting thermal and electrical power, or using renewable power for operation are a few ways to achieve more efficient and sustainable designs for LNG plants.

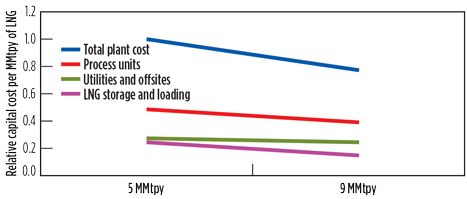

Drivers for LNG technology selection. For years, CAPEX has been the most important driver in scope and technology selection for oil and gas plants. On the client side, the focus on CAPEX has placed more emphasis on economy of scale, meaning bigger-capacity trains with significant benefits for technology development in terms of equipment size (Fig. 1).

|

|

FIG. 1. Economies of scale for onshore LNG plants.1 |

The North West Shelf plant, commissioned in the late 1980s, was the first LNG plant to use air cooling in response to local environmental restrictions.2 The concept has since been utilized at other facilities. North West Shelf was also the first plant to be fully driven by gas turbines.2 Connecting the gas turbines to the compressor shaft provides advantages in fuel efficiency and simplicity. Capital costs were reduced by the absence of boilers and steam cycle water treating facilities, and reduced overall plant cooling requirements.

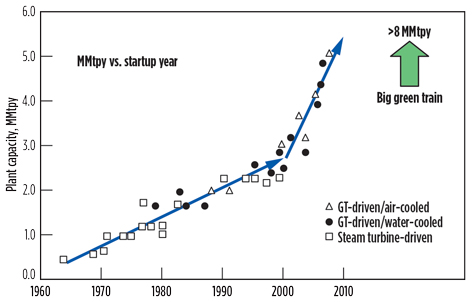

In 2005, industry predicted a trend of increasing train capacity (Fig. 2). However, some operators began focusing on LCC instead of CAPEX,3 as well as plant overall efficiency instead of refrigeration efficiency,4,5 to determine the optimum train capacity. LCC estimates also include OPEX. The present value of OPEX, if properly discounted for the 25 yr–30 yr life of LNG plants, can be nine to 10 times the actual yearly cost.

|

|

FIG. 2. Onshore LNG production capacity trends in scale in 2005.3 |

OPEX is related to several yearly costs, but plant gas consumption plays two significant roles. First, the gas burned to produce electrical and mechanical power is deducted from the LNG production as a loss. Second, the gas burned concurs with CO2 emissions load, which must be accounted in OPEX whenever a greenhouse gas (GHG) taxation system is in place. This is why the percentage of feed gas used by the LNG plant in operation is considered an important index of plant efficiency.

In September 2008, the first contract for an LNG FPSO project (FLEX LNG) was signed. The project was later canceled, but almost a year later Shell’s Prelude FLNG project was announced. FLNG has brought new constraints in capacity, but also new opportunities for process, utilities and offsites design, such as a wider range of refrigeration processes, floating storage units, and the use of cool and more-constant-temperature seawater as cooling media.

Increasing efficiency by reducing seasonal production. Ambient temperature affects demand for LNG in different ways. Gas consumers can be divided in four categories: residential, commercial, industrial and power generation. Industrial customers tend to be less sensitive to temperature and display insignificant seasonal characteristics, so the major variations are attributed to residential consumption, power generation and air conditioning.

A study6 relevant to Japan, South Korea and China highlights how the three components can merge in different ways based on the country. For instance, while in Japan the LNG consumption is higher in summer, authorities in South Korea have put in place measures to standardize LNG consumption throughout the year. Seasonal imbalances in demand often result in higher LNG prices.

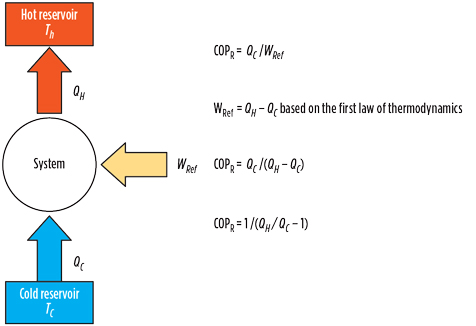

The purpose of a refrigeration system is to transfer heat from the liquefaction process to the environment through a cooling media. In air cooling, this media is the atmosphere; in water cooling, it is the sea (Fig. 3).

|

|

FIG. 3. Simplified refrigeration scheme. |

The refrigeration coefficient of performance (COPR) is an indicator of the efficiency of a refrigeration system. Higher COPR means better efficiency. For a heat pump operating at maximum theoretical efficiency, Eq. 1 is used to calculate COPR:

![]() (1)

(1)

where Tc is the temperature of the cold reservoir and Th is the temperature of the hot reservoir.

A lower temperature of the cooling media (Th) implies a higher COPR and, therefore, a higher efficiency of the refrigeration system. The power required for refrigeration is introduced in the system as compressor mechanical power; if the driver efficiency is sensitive to air temperature, then the overall LNG plant efficiency will be affected. This is the case for gas turbines; for every additional °C in air temperature, gas turbine maximum available power decreases by 0.7% for heavy-duty gas turbines and by 1%–1.2% for aeroderivative gas turbines.5

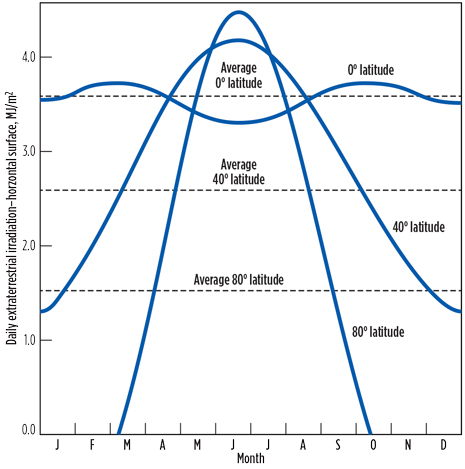

Climate conditions must be studied and accommodated for the specific site; however, air and seawater temperatures have general trends based on site latitude and elevation/depth.

To allow proper comparison, ground-level air and superficial seawater temperatures must be examined. In both cases, temperatures are determined mainly by solar radiation, which in turn depends on site latitude (Fig. 4).

|

|

FIG. 4. Seasonal variation of daily extraterrestrial solar radiation (irradiation) on a horizontal surface outside the earth’s atmosphere in the northern hemisphere.7 |

Monthly average air temperature is fairly steady at the equator, with no significant difference along the year; for example, in Singapore, the average monthly air temperature varies between 26°C and 27°C. As latitude increases, average annual temperature decreases, but the variation along the year increases. In Vancouver, monthly average air temperature is 4°C in December/January and 18°C in August, with an overall variation of 14°C.

Superficial seawater exhibits similar behavior, but the high heat capacity plays a significant role in mitigating temperature excursion along the year. In Singapore, the average monthly seawater temperature is warm and nearly constant. In Vancouver, however, the monthly average seawater temperature ranges from 8°C in February to 11°C in August, with a lower peak and a variation of only 4°C along the year.

Yearly average seawater temperature is always lower than yearly average air temperature for the same site. In high latitudes, peak water temperature coincides with peak air temperature; however, in temperate areas, peak monthly average seawater temperature shifts later in the year than peak monthly average air temperature due to water heat capacity.

Part 2 of this article will examine cooling media and compressor driver selection for small- and mid-scale LNG plants, as well as energy efficiency improvements through optimization of the electrical and thermal power balance. GP

Literature cited

- Durr, C., D. Coyle, D. Hill and S. Smith, “LNG technology for the commercially minded,” Proceedings of Gastech, Bilbao, Spain, March 2005.

- Bosma, P. and R. K. Nagelvoort, “Liquefaction technology: Developments through history,” Proceedings of the 1st Annual Gas Processing Symposium, Doha, Qatar, January 2009.

- Phillips III, R. S., T. Solis and H. Konishi, “Tangguh LNG—Energy efficiency measures through life cycle cost analysis,” Gastech, Bilbao, Spain, March 2005.

- Thomas, C. and D. Chretien, “Improving energy efficiency of LNG plants,” Proceedings of World Gas Conference, Buenos Aires, Argentina, October 2009.

- Van de Lisdonk, S., C. van Rijmenam, I. Tanaeva, G. Di Nola, M. van Loon and R. Klein Nagelvoort, “Next generation onshore LNG plant designs,” Proceedings of Gastech, Amsterdam, the Netherlands, March 2011.

- Kong, Z., X. Dong and Z. Zhou, “Seasonal imbalances in natural gas imports in major Northeast Asian countries: Variations, reasons, outlooks and countermeasures,” Sustainability, Vol. 7, Iss. 2, February 2015.

- Stine, W. and M. Geyer, Power from the Sun, eBook, January 2001, online: www.powerfromthesun.net/book.html

|

Roberto Galavotti is a consulting engineer who helps companies develop FEED capabilities, with particular focus on LNG, energy efficiency and renewable energy. He holds a degree in civil engineering from the Polytechnic University of Milan in Italy. Mr. Galavotti has worked with engineering companies, such as Saipem, Samsung Engineering and Chiyoda, for LNG FEED acquisition, development and optimization. His main research interests include clean energy, the environment and sustainability.

Comments