Gas Processing News

S & B awarded EPC contract from Phillips 66

S & B has been selected by Phillips 66 to perform engineering, procurement and construction (EPC) for two NGL fractionation plants at the client’s Sweeny Hub in Old Ocean, Texas. The plants will have a combined capacity of 300,000 bpd and will be based on S & B’s proven fractionation plant design.

The contract represents the 12th fractionation plant awarded to S & B in the last 5 yr. The company has successfully designed and constructed more than 1.3 MMbpd of fractionation capacity across the US, and another 900,000 bpd of capacity are in progress.

The work will be executed by a proven project team using S & B’s project management system (iPIMS) and advanced work packaging process (IPPTM). This execution approach will ensure that the project delivery is consistent with S & B’s commitment to safety and quality.

GTT to design tanks of new LNG carrier

GTT has received an order notification from Samsung Heavy Industries (SHI) to equip a new liquefied natural gas carrier (LNGC) with its Mark 3 Flex membrane containment system. The Mark 3 membrane system is a cryogenic liner directly supported by a ship’s inner hull. This liner is composed of a primary metallic membrane positioned on top of a prefabricated insulation panel, including a complete secondary membrane. The primary membrane contains the LNG cargo and is directly supported by and fixed to the insulation system. Offering a capacity of 180,000 m3, the unit will be built in South Korea on behalf of shipowner Gaslog. Its delivery is scheduled for 3Q 2020.

GTT (Gaztransport and Technigaz) is an engineering company that specializes in containment systems with cryogenic membranes used to transport and store liquefied gas, and in particular LNG. The company designs and provides technologies that combine operational efficiency and safety to equip LNG carriers, floating terminals and multi-gas carriers. GTT also develops solutions dedicated to land storage and the use of LNG as fuel for vessel propulsion.

GE Power reveals gas turbine, services achievements

|

GE Power’s HA gas turbine and the company’s services portfolio—including the 26th HA in commercial operation, and the new MXL2 with Additive Manufactured Performance upgrade for the GT13E2 turbine—are helping gas power producers meet growing demand for electricity in an efficient and profitable way.

According to the International Energy Agency (IEA), world energy demand is expected to rise by 30% through 2040, which is the equivalent of adding another India and China to today’s energy demand. To meet this increase in demand, natural gas, the rapid rise of renewables and energy efficiency improvements will lead the way.

GE’s HA debuted in 2016 as the world’s largest, most efficient and most advanced heavy-duty gas turbine. Since then, it has delivered two world records for efficiency across the 50-Hz and 60-Hz segments. Today, the HA has achieved more than 118,000 operating hours and is the fastest-growing fleet of gas turbines in the world, with 76 units ordered by more than 25 customers across 15 countries. Other new milestones and accomplishments include:

- Competitive Power Ventures (CPV) and its partner, GE Energy Financial Services, have achieved commercial operation at the CPV Towantic Energy Center in Oxford, Connecticut, marking the 26th HA unit to begin operations. This new plant uses two 7HA.01 gas turbines and associated engineered equipment packages. The 805-MW combined-cycle plant can provide the equivalent power needed to supply more than 800,000 US homes, and the HA’s dual-fuel capability allows the turbines to run on a variety of fuels, adding significant reliability benefits to the region.

- PSEG Power, a subsidiary of PSEG, achieved commercial operation at its Sewaren 7 combined-cycle power plant in New Jersey, powered by a 7HA.02 gas turbine and an associated engineered equipment package. The facility generates up to 540 MW, the equivalent power needed to supply more than 500,000 US homes.

- Tennessee Valley Authority’s Thomas H. Allen Fossil Plant in Memphis, Tennessee, as well as the Haveli Bahadur Shah and Bhikki power plants in Pakistan, have also recently achieved commercial operation.

- Work at the Porto de Sergipe power plant in Barra dos Coqueiros, Brazil is progressing, with three 7HA.02 gas turbines and three generators arriving at the Sergipe port in June. GE will supply the entire power island engineered package, as well as the remaining balance of the plant, such as cooling towers, roads and buildings. When complete, the plant—owned by Centrais Elétricas de Sergipe SA (CELSE)—will be capable of generating 1,516 MW, the largest gas power plant in the country. With an extensive amount of windpower and hydropower in Brazil, GE’s 7HA technology will play an important role in enabling a quick response to fluctuations in grid demand and adapting rapidly to weather changes.

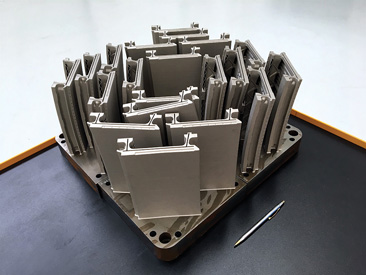

GE Power is also continuing its investments in its existing fleet. GE Power and Vattenfall Wärme Berlin AG—a subsidiary of Swedish utility Vattenfall AB—revealed the new MXL2 with Additive Manufactured Performance, the first upgrade solution for GE’s GT13E2 gas turbines that uses key components manufactured with additive technology. Since these components are made with a lightweight configuration and can be engineered to include advanced cooling channels, they help the gas turbine run more efficiently, representing a new frontier in turbine engineering and production. This technology can significantly elevate the output and efficiency of existing 13E2 gas turbines, and is capable of the following:

- Reducing component cooling requirements by up to 25%

- Increasing output up to 21 MW in a combined-cycle configuration

- Achieving additional efficiency up to 1.6% in a combined-cycle configuration

- Delivering maintenance intervals of up to 48,000 hr.

The new MXL2 with Additive Manufactured Performance can help gas plant power producers save up to $2 MM/yr in fuel, while opening up the potential for additional revenue of up to $3 MM/yr in new power capacity. This underpins GE’s commitment to keep its mature fleets competitive in today’s dynamic marketplace.

Baker Hughes, a GE company, selected for rotating equipment

Global LNG Services (GLS) is making significant progress for the Main Pass Energy Hub (MPEH) Deepwater Port project, owned by its US subsidiary, MPEH LLC, and located 16 mi offshore southeast Louisiana in the Gulf of Mexico. Two LIQUI-MAX vessels, capable of producing a total of 24 MMtpy of LNG, will be permanently stationed at MPEH.

GLS’ LIQUI-MAX vessel design uses all industry-standard equipment in a unique configuration, allowing expanded throughput and resulting in an unprecedented CAPEX of less than $400/tpy of liquefaction capacity. GLS’ cost advantage enables it to introduce a floating tolling fee model with a floor rate of Henry Hub plus 15% plus $1.50/MMBtu for pre-processing and liquefaction, and 50/50 sharing of the liquefaction netback value above the $1.50/MMBtu level.

Gas will be sourced through interstate pipelines and preprocessed onshore in the Louisiana, Mississippi and Alabama regions. Baker Hughes, a GE Company (BHGE), was selected by GLS for both its technology and extensive experience in LNG equipment and services. The LM9000 gas turbine leverages scale to provide effective LNG solutions, thanks to its higher power output on a smaller footprint, its best-in-class efficiency and the latest Dry Low Emission (DLE) technology. The LM9000 development, led by BHGE, is the latest in

a proven legacy of building robust gas turbines from world-class aircraft engines.

GLS was established in 2012 with the goal to develop, own and operate clean, safe and cost-efficient floating liquefaction vessels. GLS acquired MPEH LLC and the MPEH project from Freeport-McMoRan Energy LLC in 2016. MPEH was previously permitted by the Maritime Administration (MARAD) as an LNG import facility, and is ideally located in the Gulf of Mexico to allow efficient marine vessel access to the facility.

Tokyo Gas, Centrica sign LNG purchase HoA

|

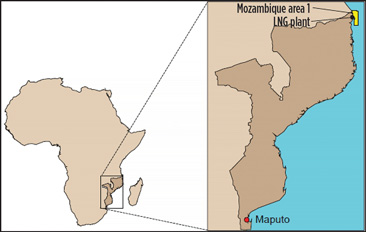

Tokyo Gas Co. Ltd. and Centrica LNG Co. Ltd., a subsidiary of UK-based energy and services company Centrica Plc., have jointly signed a non-binding heads of agreement (HoA) with the jointly-owned sales entity of the Mozambique Area 1 JV partners for the long-term offtake of LNG.

Tokyo Gas and Centrica have agreed to jointly purchase 2.6 MMtpy delivered by ship from the Mozambique LNG project from the startup of production through the early 2040s. The supply agreement provides the project with key foundation customers that will facilitate the final investment decision by the Mozambique Area 1 JV partners.

Tokyo Gas and Centrica signed a memorandum of understanding (MoU) in November 2016 to collaborate in their LNG activities. This co-purchase agreement is a significant step toward the goal set out in this MOU, and further deepens the relationship between the two companies.

This groundbreaking joint procurement scheme between a UK-based and a Japan-based company takes full advantage of Mozambique’s central location between Europe and Asia to assist both companies in proactively managing demand fluctuations across regions. The transaction represents the first long-term offtake agreement from Africa for both Tokyo Gas and Centrica in line with ongoing efforts to further diversify their respective portfolios of LNG sources. This will also enhance the liquidity and further development of the global LNG market.

Tokyo Gas Co. Ltd. is Japan’s largest provider of city gas, serving more than 11 MM customers,

primarily in the Tokyo metropolitan area and surrounding Kanto region. International energy and services company Centrica supplies energy and services to 276 MM customer accounts, mainly in the UK, Ireland and North America.

PGNiG, Port Arthur LNG sign US LNG agreement

|

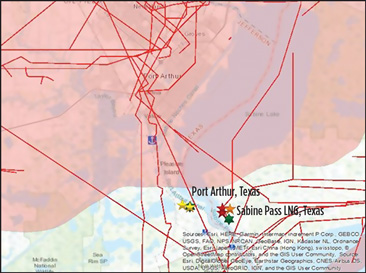

Polish Oil & Gas Co. (PGNiG) and Port Arthur LNG, a subsidiary of Sempra LNG & Midstream, have entered into an agreement relating to the terms of delivery of LNG from the Port Arthur liquefaction facility.

The agreement defines basic terms and conditions of a 20-yr contract to be finalized between the parties for the sales and purchase of 2 MMtpy of LNG, which is equivalent to 2.7 Bm3y of natural gas following regasification. Cargoes will be supplied, starting in 2023, from the Port Arthur LNG facility being developed in Jefferson County, Texas.

Deliveries will allow further trading by PGNiG on international markets and are thought to be supplied on a free-on-board (FOB) basis, whereby PGNiG is responsible

for transport of the cargoes from Port Arthur LNG.

The agreement represents another step in the ongoing development of the Port Arthur LNG liquefaction project. In 2017, Sempra LNG & Midstream signed an MOU with Korea Gas Corp. (KOGAS) to provide a framework for cooperation, including engineering and construction, operations, equity ownership in the Port Arthur LNG liquefaction project and offtake of LNG. The ultimate participation of KOGAS and PGNiG in the project remains subject to finalization of definitive agreements.

The Port Arthur LNG liquefaction facility is planned to export approximately 11 MMtpy of LNG starting from 2023. Bechtel was selected by Port Arthur LNG to be the engineering, procurement, construction (EPC) and commissioning contractor. Development of the Port Arthur LNG liquefaction project is contingent upon obtaining customer commitments, completing the required commercial agreements, securing all necessary permits, obtaining financing and incentives, and reaching a final investment decision.

Trelleborg supplies solutions to India FSRU

|

Trelleborg’s marine systems operation has supplied a suite of products to H-Energy’s floating storage regasification unit (FSRU)-based LNG terminal at JSW Infrastructure’s Jaigarh Port in Ratnagiri District, Maharashtra, India.

Developed in accordance with industry-leading engineering and safety standards, H-Energy’s 4-MMtpy LNG terminal will offer storage, regasification, reloading, fuel bunkering and truck loading facilities to cater to the growing energy demand of Indian industries. Once operational in 4Q 2018, the regasified LNG will be supplied to customers through a 60-km tie-in pipeline that will be connected to a national gas grid at Dabhol.

Trelleborg supplied the terminal with its Quick Release Hook units, Environmental Monitoring system, SmartDock docking aid system and Central Integrated Monitoring system. The project was managed by Trelleborg’s experienced project team in Melbourne, Australia, while engineers from Trelleborg’s engineering and design center of excellence in Ahmedabad, India carried out the inspection and commissioning of the mooring equipment and attended the successful berthing of the FSRU.

ManMohan Ahuja, Project Director of H-Energy, commented, “With India being one of the fastest-growing countries across the globe, its energy consumption continues to rise at a rapid rate. The country’s need for clean, safe and affordable fuel has never been greater … The first FSRU-based LNG terminal at Jaigarh Port aims to deliver exactly that.”

The suite of products supplied by Trelleborg falls under its SmartPort portfolio, which is the company’s answer to the need for a standardized way to collect, store, analyze and present data. The technology platform seeks to connect all aspects of port operations, allowing users to analyze asset performance and apply data insights to improve day-to-day decision-making.

Comments