Gas processing news

B. Andrew, Technical Editor

GTI celebrates 75 years

Gas Technology Institute (GTI) recently celebrated an important milestone—its 75th anniversary. As a leading research and development (R&D) and training organization addressing global energy and environmental challenges, GTI spent the last seven-plus decades developing high-impact technologies and providing technical insight to unlock the potential of natural gas and other energy resources. GTI’s aim is to make these technologies economically and environmentally sustainable while simultaneously reducing energy costs for consumers.

GTI also has a solid reputation for developing gas distribution tools and technologies that reduce energy delivery costs. Experts have created a wealth of solutions to enhance the safety and integrity of the nation’s vast pipeline infrastructure and target critical global methane emissions issues.

The organization has achieved many successes over its history, focusing on initiatives aligned

with important national priorities. GTI has provided solutions to critical challenges along the

entire gas value chain and improved the ways of producing, transporting, and using energy

to benefit the general public.

R&D projects through the decades have expanded the supply and reduced the environmental footprint of unconventional gas production. Cleaner ways to use abundant coal resources have been generated and brought to market through GTI-patented processes. Groundbreaking efforts to convert wood into renewable “drop-in” gasoline in GTI’s integrated biorefinery have resulted in a sustainable biofuel with 74% lower greenhouse gas emissions than petroleum-based fuel.

Promoting the clean and efficient use of energy resources across all end-use markets—residential/commercial, industrial, power generation, and alternative compressed natural gas and hydrogen transportation—and contributing to the progress of US green building practices are among GTI’s contributions. GTI is developing a portfolio of affordable equipment and appliances with reduced energy consumption and emissions, which will contribute to improving air quality for decades to come.

Gas jet ejector extends field life

|

GEA has designed, manufactured and delivered a gas jet compressor system for an offshore platform in the North Sea consisting of a jet pump (ejector) with a total length of 4.5 m, and silencers to reduce the sound pressure level. At a newly drilled well, natural gas is available with a pressure of up to 600 bar. The gas pressure decreases in the course of exploitation of the gas field. At a defined gas pressure, the gas delivery rate is so low that the mechanical compressor is no longer economical.

Gas jet compressors are designed to increase the natural gas pressure and to allow extension of the use of the installed mechanical compressors. In this way, the gas field life is prolonged. The system compresses a low-pressure natural gas (8 barg) by using a high-pressure natural gas (90 barg) to an intermediate gas pressure (12 barg). GEA managed to increase its portfolio by designing the ejector body for 137 barg, and on the motive side for 213 barg.

The material of construction is corrosion-resistant and corrosion-tested duplex stainless steel, which is coated with sprayed aluminum. Ejectors are reliable in operation at low operating costs. They are nearly maintenance-free because they are simply constructed, having no moving parts. Almost any vacuum duty can be accommodated, including large suction flows.

Engineer chosen for Elba LNG project

|

HDR Inc. has been selected as the owner’s engineer for Kinder Morgan’s LNG export project at Elba Island near Savannah, Georgia. The project is in the engineering, procurement and construction phase.

The Elba liquefaction project will include installation of 10 liquefaction units for an output capacity of approximately 2.5 MMtpy of LNG, and modifications to the existing Elba Terminal to allow for export.

The project will use Shell’s small-scale liquefaction units, which will be integrated into the existing Elba terminal and enable rapid construction compared to traditional large-scale plants.

Kinder Morgan is also working with ABSG Consulting Inc., a subsidiary of ABS Group of Companies Inc., for the development of a maintenance and integrity program for the terminal. ABS Group will develop the program for the base plant, balance of plant and the terminal upgrade.

3D-printed polymer turns methane to methanol

|

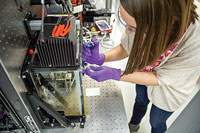

Lawrence Livermore National Laboratory (LLNL) scientists have combined biology and 3D printing to create the first reactor that can continuously produce methanol from methane at room temperature and pressure. The team removed enzymes from methanotrophs—bacteria that eat methane—and mixed them with polymers that were then printed or molded into innovative reactors. LLNL found that isolated enzymes offer the promise of highly controlled reactions at ambient conditions with higher conversion efficiency and greater flexibility.

Advances in oil and gas extraction techniques have made vast new stores of natural gas, composed primarily of methane, available. However, a large volume of methane is leaked, vented or flared during these operations, partly because the gas is difficult to store and transport compared to more valuable liquid fuels. Methane emissions also contribute approximately one-third of net global warming potential, primarily from these and other distributed sources, such as agriculture and landfills.

Existing industrial technologies (such as steam reformation) to convert methane into more valuable products operate at high temperature and pressure, require a large number of unit operations and yield a range of products. As a result, these technologies have a low efficiency of methane conversion to final products, and can operate economically only at very large scales.

A technology to efficiently convert methane to other hydrocarbons is needed as a profitable way to convert stranded sources of methane and natural gas to liquids for further processing. The only known catalyst (industrial or biological) to convert methane to methanol under ambient conditions with high efficiency is the enzyme methane monooxygenase (MMO), which converts methane to methanol. The reaction can be carried out by methanotrophs that contain the enzyme, but this approach inevitably requires energy for upkeep and metabolism of the organisms. Instead, the LLNL team separated the enzymes from the organism and used the enzymes directly. GP

Comments