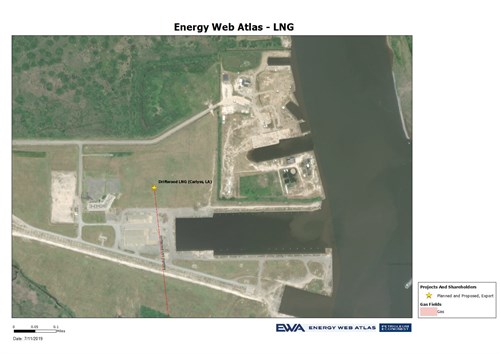

Tellurian, Total finalize Louisiana Driftwood LNG export plant agreements

U.S. liquefied natural gas (LNG) developer Tellurian Inc said that units of French oil major Total SA have agreed to buy LNG from the U.S. company’s proposed $30 billion Driftwood export project in Louisiana.

|

| Source: EWA |

Total will buy one million tons per annum (mtpa) of LNG from Driftwood and invest $500 million in Driftwood Holdings LP, it said in a statement.

Total will also buy an additional 1.5 mtpa of LNG from Tellurian’s offtake volumes from Driftwood. The deal involves LNG free on board at a price based on the Platts Japan Korea Marker (JKM).

Tellurian said it planned to make a final investment decision this year on whether to build Driftwood, which would enable the plant to enter service in 2023.

“The agreements we have executed with Total confirm the business model for the Driftwood project, establishing it as an LNG joint venture partnership with an implied value of $13.8 billion,” Tellurian President and Chief Executive Meg Gentle said in the statement.

Driftwood is designed to produce 27.6 mtpa of LNG or about 4 billion cubic feet per day (bcfd) of natural gas. One billion cubic feet of gas is enough to fuel about 5 million U.S. homes for a day.

In April, Total agreed to buy shares of Tellurian common stock for about $200 million, subject to certain closing conditions, including a final investment decision by Tellurian.

Tellurian said Total’s aggregate investment in the Tellurian portfolio will be about $907 million at the time of the final decision to build the plant.

Driftwood is one of about a dozen U.S. LNG export projects that said they could make final investment decisions in 2019. Together the plants, which analysts said will not all be built, would produce over 150 mtpa of LNG.

Total world demand for LNG reached a record 316 mtpa in 2018 and is projected to soar by about 100 mtpa by 2023, according to the U.S. Energy Information Administration.

Unlike most proposed U.S. LNG export projects that will liquefy gas for a fee, Tellurian is offering customers the opportunity invest in a full range of services from production to pipelines and liquefaction.

Current partners include units of Total, Vitol, Petronet LNG Ltd, General Electric Co and Bechtel, which has a $15.2 billion contract to build the liquefaction facility. Pipelines, reserves and other expenses make up the rest of the project’s cost.

Reporting by Scott DiSavino; Editing by Richard Chang

- Freeport LNG export plant in Texas to take in more natgas after unit shut on Monday

- LNG cool-down vessel arrives at ExxonMobil's Golden Pass plant in Texas

- Freeport LNG export plant in Texas reports shutdown of liquefaction train

- TotalEnergies and Mozambique announce the full restart of the $20-B Mozambique LNG project

- JGC celebrates handed over second production train to LNG Canada

Comments