Sulzer GTC showcases process technologies ahead of IRPC Americas ONLINE

By Adrienne Blume, Executive Editor, Hydrocarbon Processing

A pre-conference Innovation Showcase on the afternoon of September 21 educated attendees on a number of innovative technologies and processes licensed by Sulzer GTC Technology.

High-purity aromatics extraction. The workshop opened with a session on GT-BTX Aromatics Recovery and GT-BTX PluS technologies, introduced by Joseph (Joe) Gentry, Senior Vice President of Licensing and Engineering, and presented by Charlie Chou, Licensing Director of Refining, Aromatics and Derivatives.

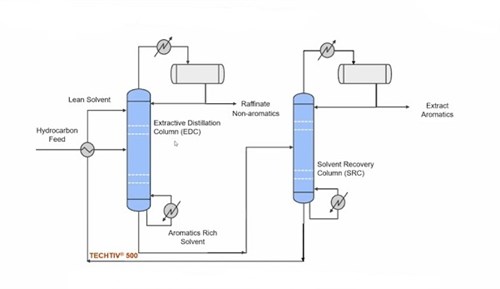

GT-BTX takes pygas, reformate and coke oven light oil streams to efficiently extract aromatics via extractive distillation (ED) in a two-column system (see Fig. 1). The use of the Techtiv 500 solvent in the GT-BTX process makes it among the highest-efficiency ED processes. GT-BTX is in use in more than 60 grassroots and revamp units around the world, and is the only ED technology that can extract high-purity benzene, toluene and xylene (BTX) together at more than 99.9% recoveries.

GT-BTX PluS technology converts FCC naphtha into high-quality, low-sulfur FCC gasoline or BTX, using the Techtiv DS solvent. GT-BTX PluS is the only ED technology that can successfully process FCC gasoline without sacrificing octane.

Figure 1. Extractive distillation scheme

Advanced hydrotreating with MaxFlux. The innovation showcase continued with a talk on MaxFlux advanced hydrotreating technology by Matthew Clingerman, Business Unit Leader for MaxFlux. The novel hydrotreating process, which encompasses a reactor with two catalyst beds, eliminates mass-transfer bottlenecks by dissolving hydrogen in the liquid hydrocarbon. These characteristics contribute to improved performance and increased operating flexibility for all kinds of hydrotreating operations.

MaxFlux also reduces CAPEX by eliminating the recycle gas separation and treating loop, decreases OPEX by reducing electricity and fuel gas consumption, and increases both product yield and catalyst life by eliminating hotspots, over-cracking and coking. The technology family also includes the BioFlux process for renewable diesel production.

Excellent in isomerization. Zhepeng Liu, Business Unit Leader for Isomalk, next discussed Isomalk Technology. The Isomalk family covers three technologies for isomerization of C4, C5/C6 and C7, as well as naphtha management. The processes utilize various grades of Sulzer GTC's SI Catalyst. The process technologies offer reduced CAPEX and OPEX and competitive yields of final products, as Liu demonstrated through a number of case studies.

Reduce CAPEX, footprint with DWC. Gary Martin continued the showcase by informing attendees about the use of dividing wall column (DWC) technology in advanced distillation operations. The use of DWCs can help lower CAPEX by 20%–30% by combining two or more columns into a single column and by reducing peripheral equipment, energy usage and plot space/footprint (the latter by up to 30%). DWCs are also known for their role in producing high-purity products. Sulzer GTC has more than 65 references for DWCs.

Best practices for pygas processing. Concluding Sulzer GTC Technology's Innovation Showcase, Sachin Joshi discussed the Pygas HDT and GT-Styrene technologies, which enable the recovery of styrene monomer and benzene from pygas. This increases the value of products from the steam crackers and improves pygas processing. GT-Styrene is an effective complement to world-scale naphtha or mixed-feed crackers and is licensed at seven units worldwide, three of which have been in operation for more than five years.

For more information on Sulzer GTC Technology offerings, please visit www.gtctech.com. And don't forget to attend IRPC Americas ONLINE from September 22–23. Visit www.irpc-americas.com for more information.

- RWE strengthens partnerships with ADNOC and Masdar to enhance energy security in Germany and Europe

- TotalEnergies and Mozambique announce the full restart of the $20-B Mozambique LNG project

- Venture Global wins LNG arbitration case brought by Spain's Repsol

- KBR awarded FEED for Coastal Bend LNG project

- Norway pipeline gas export down 2.3% in 2025, seen steady this year

Comments