Japan power plant to boost output with GE technology

TOKYO—As the Japanese electricity segment booms with liberalization dynamics and ongoing deregulation, but faces a decline in power demand, a stable power supply is the number-one priority for energy players in the country.

JFE Steel Corp. (JFE), faced with aging energy infrastructure, has employed GE's Power Services business to help modernize, increase output and improve operational flexibility at its Chiba combined-cycle power plant.

"In Japan, the recent deregulation of the electric power industry is causing a shift in the energy landscape," said Satoshi Ogino, Manager of the Energy Technology Section for the Energy Department of JFE's East Japan Works.

"The industry competition is intense, with a lower barrier of entry for new power generation players. To sustain competitiveness, existing power generation operators with longstanding histories, like JFE, are constantly looking at adopting modernized power plant solutions and services, ensuring energy security and optimized plant operation."

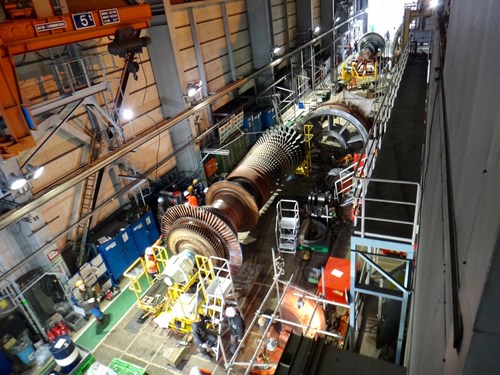

GE's modernization efforts consisted of a MXL2 gas turbine upgrade, a low-pressure steam turbine retrofit and a new lifetime management concept on the GT26 gas turbine. These upgrades are expected to increase the output of the gas turbine by up to 60 MW.

In addition, they will help improve operational flexibility for JFE and extend maintenance intervals of the turbine.

As part of a multi-year agreement signed by the two companies, GE will also provide operations and maintenance support at the facility for the next 15 yr, and a small number of GE personnel will be onsite to assist and provide consultation to JFE on its plant operations.

This project is the first for GE in Japan that exploits its full capacity stemming from its acquisition of Alstom's power business in 2015. GE delivered a full turnkey project to upgrade the entire power station as a result of its expanded capabilities.

The modernizations included gas turbine, boiler and balance of plant—under comprehensive project management, from process management to restarting the plant within the required designated downtime period.

- RWE strengthens partnerships with ADNOC and Masdar to enhance energy security in Germany and Europe

- TotalEnergies and Mozambique announce the full restart of the $20-B Mozambique LNG project

- Venture Global wins LNG arbitration case brought by Spain's Repsol

- Mitsubishi Heavy Industries Compressor acquires Swiss rotating equipment maintenance company AST Turbo AG

- KBR awarded FEED for Coastal Bend LNG project

Comments