Pipeline isolation technology reduces project time and cost

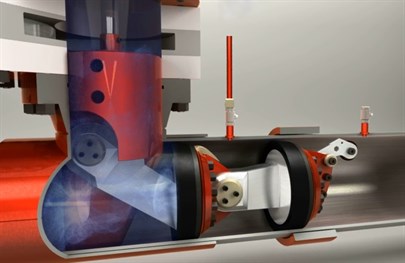

Photo courtesy of T.D. Williamson.

The ability to safely execute repairs and modifications on high pressure pipelines while they remain in service can save operators significant time and expense, but relies on isolating the work zone and preventing product seepage.

A typical double block and bleed isolation involves tapping the line in two places and inserting temporary block valves along with a drain or vent to evacuate any product between the two seals.

Stopple Train double block and bleed technology is distinct in that it requires just a single tap. Two fully rated independent temporary block valves connected in a train formation are inserted into the tap, reliably providing two workable seals. A bleed port between the two seals is large enough to vent away any gas or viscous liquid that passes the primary seal.

According to Kyle Whiteis, T.D. Williamson (TDW) senior product manager, reducing the number of taps from two to one can cut project costs and schedules, with 50% fewer fittings and machines on the line and 50% less time required to execute the tapping, isolation, and plugging processes.

“Regardless of the economic environment, those financial benefits are extremely important on jobs of all sizes,” Whiteis says. “But the savings are even more pronounced when you’re talking about larger diameter pipelines where changing out the equipment on a conventional double block and bleed configuration could take an enormous amount of time.”

In addition to reducing time and expenses, STOPPLE Train isolations are also associated with lower risk. Not only does the single tap reduce potential leak paths, the reduction in welding, tapping, isolating, and other job site activities can translate to improved safety.

- RWE strengthens partnerships with ADNOC and Masdar to enhance energy security in Germany and Europe

- TotalEnergies and Mozambique announce the full restart of the $20-B Mozambique LNG project

- Venture Global wins LNG arbitration case brought by Spain's Repsol

- Mitsubishi Heavy Industries Compressor acquires Swiss rotating equipment maintenance company AST Turbo AG

- KBR awarded FEED for Coastal Bend LNG project

Comments