Membrane system allows ethane transport on LNG carriers

By Julie Sakhrai

A significant amount of surplus ethane is available in the US as a result of the shale gas revolution. Surging ethane extraction capability in US shale plays has given the chemical a price advantage relative to naphtha and made it a viable export commodity.

According to recent forecasts, US ethane extraction capacity has increased by 69% since 2006 to 1.23 MMbpd, and it is projected to reach 2.2 MMbpd by 2020. Ethane exports are forecasted to reach 150 Mbpd to 200 Mbpd in the next five to six years.

Interest in ethane as a product that will require dedicated shipping is on the rise. Recently placed ethane export orders must be transported in containment systems on very large gas carriers (VLGCs). Ethane, which is shipped at −92°C, can also be transported in the systems designed for LNG carriers.

Membrane technology is a preferred choice in the LNG shipping market, and it also stands as a viable solution for cargo containment systems (CCS) on VLGCs. Engineering company GTT has provided membrane system designs for the sea transport of ethylene and LPG since 1964, with five carriers ranging from 1,100 m3 to 120,000 m3.

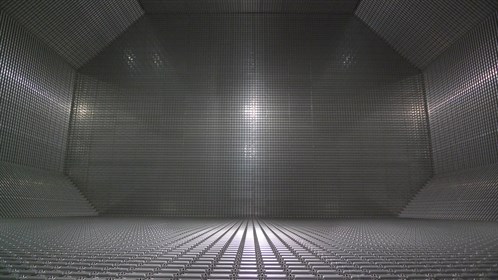

GTT's Mark III membrane system

Shell's LNG FPSO will be equipped with GTT membrane tanks for LNG storage, along with other tanks to be used for LPG, with a total capacity of 90,000 m3.

The GTT CCS is supported by a hull structure that provides a competitive advantage in terms of volumes to be transported. The membrane presents a flexible solution that is adaptable to any cargo space available, and the increase in density is not a barrier to the adaptation of the tanks.

Hull structure supporting the GTT CCS

Additionally, GTT's system provides a cost advantage and additional safety. The four AIPs received from class societies confirm the membrane's position among the range of containment systems. All existing GTT technologies are applicable to ethane transportation.

GTT's membrane technology also addresses growing market needs. The CCS is not limited to the transport of ethane and LNG; it is also applicable for other liquefied gases, like ethylene, propane, butane, etc. The membrane technology allows for the simultaneous transport of different gases, providing operational and commercial flexibility.

The CCS also allows for the optimization of volumes to be stored in each tank. For example, a four-tank VLGC with a capacity of 84 km3 could achieve a capacity range of 9 km3 to 84 km3.

Other containment technologies are available, although they are limited to the carriage of LNG cargoes, which means that the approval of tanks for heavier liquefied gases must be carefully evaluated.

GTT's technical contact is François Durand, project leader of the company's innovation division. He can be contacted by email.

- ExxonMobil halts 1-Bft3d blue hydrogen project in Texas

- Aramco and Yokogawa commission multiple autonomous control AI agents at Fadhili gas plant

- Ukraine will resume gas imports via Transbalkan route in November

- Mitsubishi to inject $260 MM into Brunei LNG project

- Freeport LNG (U.S.) on track to take in more natgas on Thursday after unit outage

Comments