Evaluate train size, drivers and digitalization options for mid-scale LNG

M. Russell and J. Adams, Siemens, Houston, Texas

In some select cases, mid-scale LNG trains (0.5 MMtpy–2 MMtpy) may offer commercial, logistical and financial advantages over large-scale LNG trains. However, the decision is not “one-size-fits-all,” as large trains (> 3 MMtpy) offer economies of scale, among other benefits.

Selecting a solution that delivers the most value over the life of a project is contingent on the operator’s objectives and circumstances. Ultimately, train size and liquefaction licensor selection have only a marginal impact on project capital cost, as long as the facility achieves a minimum production capacity of 8 MMtpy.1

Objective cases are offered here for the construction of both mid-scale and large-scale trains. Key areas are outlined for project stakeholders to consider when making decisions on capacity and liquefaction licensor. Considerations for optimizing LNG plant design, such as mechanical driver selection, modularization and the incorporation of digital technologies, are also discussed. A holistic strategy integrates the entire gas value chain in an effort to drive down costs, minimize risk and maximize overall project economics.

Development of mid-scale LNG concept. In 2014/2015, cost overruns and schedule delays for LNG projects combined with the fear of oversupply to force developers to look for ways to drive down costs and stimulate LNG sales. In addition to rethinking construction methodologies, supply frameworks, shipping routes, transportation and other aspects, a concept that garnered a great deal of attention from owners and developers was the idea of scaling down train sizes. During this time, the concept of mid-scale LNG began to gain traction.

The mid-scale LNG concept focuses on using modularization and standardization to reduce development costs and accelerate gas delivery to market. It has also been viewed as a means to increase overall plant capacity in accordance with market demand and feed gas availability. Additionally, claims have been made about the operational benefits offered by mid-scale LNG, such as increased turndown flexibility.

Overall, train size and technology selection remain key areas of focus for LNG developers and engineering, procurement, and construction (EPC) firms. In select cases, mid-scale LNG trains may offer commercial, logistical and financial advantages, although the decision on train size will ultimately rest on the operator’s objectives and circumstances, as well as the ability to incorporate innovative approaches and technologies (e.g., digitalization and electric-driven compressors).

LNG market overview and project drivers. Over the past two decades, the trend dominating the LNG market has been to build large baseload facilities. Many LNG plants today consist of two trains with a total output of 10 MMtpy–14 MMtpy. In an effort to mitigate the risk of cost overruns and schedule delays, an increasing number of recent projects have proposed a series of mid-scale trains to produce the equivalent of two large baseload trains.

In addition to providing the capability to monetize smaller volumes of gas and bring low-cost, incremental value to existing facilities, reduction in train size may be a better match for the needs of the evolving LNG market, which has seen the number of importing countries nearly quadruple from 2000 to 2017.2

Contract lengths and offtake volumes have also changed, with new buyers seeking 5 yr–10 yr agreements for 1 MMtpy–2 MMtpy of LNG, in addition to the traditional 15 yr–20 yr contracts for 5 MMtpy–7 MMtpy, which are still required to make new LNG facilities financeable.

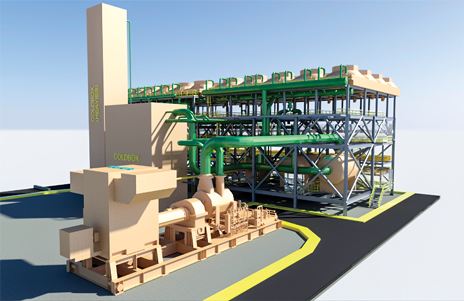

All of these factors have driven LNG owners and project developers to begin exploring new technical, logistical and commercial strategies to reduce risk while remaining competitive. Mid-scale LNG (Fig. 1) represents a potential solution.

|

| FIG. 1. Rendering of a mid-scale LNG plant layout. |

Large-scale LNG vs. mid-scale LNG. Financial analyses show that with a minimum facility size of approximately 8 MMtpy, the choice of liquefaction technology licensor and train size does not have a significant impact on cost.

On average, liquefaction accounts for approximately 25% of an LNG export facility’s capital cost. Within the liquefaction scope, the average cost variation from licensor to licensor is around 25%–30%. This means that the decision of technology and train size impacts the total capital cost of the LNG facility by only 5%–7%.1

Since approximately 75% of EPC project capital costs for LNG export facilities fall outside of the liquefaction scope, the greatest immediate opportunity for developers and operators to leverage mid-scale LNG and achieve project cost savings in today’s environment is brownfield expansion projects.

In brownfield projects, remaining incremental capacity in existing infrastructure—i.e., utilities, tanks, marine facilities and balance of plant systems—enables the developer to implement a mid-scale train without making significant investments in new infrastructure. The deciding factor becomes how much incremental capacity can be added before the underlying infrastructure must be expanded.

Adding incremental capacity through mid-scale trains, without touching the balance of plant, represents an efficient strategy for lowering the cost of bringing LNG to market. As previously mentioned, the implementation of a mid-scale train also provides the developer with the option to add units as determined by offtake and feed gas availability. In certain cases, mid-scale LNG also represents a more attractive option to investors and stakeholders, as it is generally easier to finance a project of less than $1 B than a $5-B-plus project.

Overall, mid-scale LNG is emerging as a potential solution to reduce costs and meet the needs of the evolving LNG market. However, large-scale trains offer economies of scale and they are technically proven worldwide, which inevitably reduces the risk profile of an LNG project and makes it more bankable.

Reducing cost and optimizing plant design. Other decisions that impact LNG export facility project CAPEX, OPEX and total cost of ownership (TCO) include mechanical driver selection, modularization and digitalization.

Driver selection. Determining the optimal configuration of equipment and refrigeration cycle for liquefaction requires careful consideration of variables, such as gas composition, ambient temperature, reliability, weight and size limitations, safety, maintainability, etc. After a specific refrigeration cycle has been chosen, the equipment configuration that will be used to drive refrigeration compressors must be chosen.

Each configuration presents its own unique advantages, disadvantages and subsequent trade-offs concerning CAPEX, OPEX, efficiency, availability, maintenance and emissions. Selecting the option that will provide the most value over the life of the facility is largely dependent on project-specific objectives. Some considerations for different driver options are discussed below:

- Steam turbines provide excellent reliability, as well as flexibility on the type of fuel gas they can accept. However, they typically exhibit poor thermal cycle efficiency and require a large footprint. They also often require a dedicated steam/water network, which can increase project complexity and drive up costs.

- Heavy-duty gas turbines (HDGTs) have been the most widely used driver for liquefaction operations over the last 20 yr. The thermal efficiency of HDGTs ranges from 30 %–38%, although that percentage decreases as ambient temperature increases. A key advantage of HDGTs is that they are available in a wide range of sizes/capacities, thereby allowing operators to design fit-for-purpose trains to maximize efficiency. Notable drawbacks include high specific fuel consumption, which leads to increased emissions. Additionally, single-shaft HDGTs are limited with regards to torque and speed variation, and often require higher maintenance than other driver options.

- Aeroderivative gas turbines (ADGTs) have become an increasingly popular driver option for liquefaction. They are lightweight and relatively easy to replace, and can achieve higher thermal efficiency (40%–43%) and lower emissions. Additionally, aeroderivative turbines do not require large starter motors. Multiple ADGT driver configurations typically must be used in parallel to meet production requirements, especially in large-scale LNG operations. This can be advantageous, as it allows operators to maintain partial production.

- Electric motors offer a number of advantages compared to gas and aeroderivative turbines, particularly with regard to availability. When power supply is generated from a renewable source, they also produce fewer emissions. Electric motors are an attractive option in applications where uptime is paramount and maintenance requirements are lower; however, they do require significant upfront investment in connecting to a dedicated power source. A modern LNG compression concept, electrically driven compression (eLNG) with a combined-cycle power plant (CCPP) (Fig. 2), offers a solution with higher flexibility, greater efficiency (on the order of 50%) and improved availability while minimizing environmental impact.

Selection of driver type and configuration will have a significant impact on the overall performance and efficiency of an LNG plant. Ultimately, this decision must be made at the earliest possible phase of the project. Poor scope definition and equipment selection will also increase the likelihood of problems.

In some instances, it may be advantageous to conduct two separate, simultaneous, front-end engineering design (FEED) studies with two different EPCs, with each EPC implementing different solutions with one original equipment manufacturer (OEM). The integrated FEED team can select an arrangement that best aligns with project requirements for CAPEX, OPEX, efficiency, reliability, maintenance and emissions.3

Modularization strategies. Modularization of LNG facilities is an effective strategy for mitigating the risk associated with project cost overruns and schedule delays, which often occur as a result of complications during onsite construction. While modularization has traditionally been viewed as a way to achieve schedule savings, it can also help achieve labor costs savings. Such savings have been observed in module developments across Asia and for LNG plants being built in harsh and/or remote operating environments.

In such environments, a concept that has proven effective is “plug-and-play” modular e-houses. E-houses are pre-fabricated electrical substations that are fully equipped with medium-voltage switchgear, low-voltage switchboards, busbar trunking systems and auxiliary equipment. They are an optimal approach to installing electrical power and control equipment for a fast and reliable power supply in harsh and/or remote environments.

|

|

FIG. 2. Natural gas-fired CCPPs at Beni Suef in Egypt, each with a capacity of 4.8 GW. |

A standard e-house consists of one module. Multi-modular e-houses are also available and consist of several modules that are placed on a foundation, either on top of or next to one another. This enables transportation of large houses, and ensures optimal use of available space. E-houses can be installed on raised platforms to protect them from flooding, and to enable the installation of cable tray and bus duct systems underneath the structure, thereby minimizing the need for excavation.

Digitalization. An early determination of how digitalization will be built into an LNG plant is another critical design decision that can reduce TCO by lowering OPEX, reducing complexity and offering increased flexibility to accommodate project changes.

Digitalization in LNG consists of harnessing and analyzing real-time and historical data, as well as asset design data, to provide decision support and optimize overall performance through improved reliability and integrated operations management.4 LNG plant operators can realize quantifiable benefits by embracing an end-to-end digital strategy, using proven tools and strategies, such as smart sensors, the cloud, data analytics, artificial intelligence, machine learning and digital twins:

- Smart sensors. Digital applications can exploit the development of low-cost, smart sensors. These sensors give an LNG facility’s equipment baseline performance “signatures” that enable real-time monitoring and analysis of any operating data anomalies. Enhanced measurements can improve availability via more accurate predictive diagnostics.

- Connectivity to cloud infrastructure. Affordable, secure links to global, scalable, cloud-based computing and storage resources on a “pay-as-you-go” basis lower entry costs and simplify application deployments for LNG operations. Global standards facilitate machine-to-machine communication, reducing proprietary lock-ins on how equipment communicates with other systems. New and legacy infrastructures can exchange information, helping extend the utility of older equipment and the value of legacy investments.

- Data analytics. The data science behind advanced analytics includes sophisticated statistical models that seek patterns in data at superhuman speeds. The use of advanced analytics has traditionally been constrained by cost and access to the required computer capability, but cloud computing has made this power more accessible, affordable and scalable.

- Artificial intelligence (AI) and machine learning. AI is the application of computer technology to perform tasks that would usually require human intelligence and cognition. Machine learning is an AI application that runs data through sophisticated statistical models to find patterns and, in effect, to learn from the data and adapt its functions without specific programming. The more data that is processed, the smarter the program or machine becomes.

- Digital twins. With computer-aided design, engineering and manufacturing software, it is possible to integrate all asset data to build a virtual representation (i.e., a digital twin) of a physical asset. For greenfield projects, the digital twin can be used to minimize capital cost by effectively comparing design options. It can also be used to reduce cycle times and engineering efforts. In the operational phase, the digital twin provides the ability to compare operations to design conditions and to quickly and cost-efficiently conduct “what-if” scenarios.

A holistic digital approach using the outlined tools and strategies represents an enormous opportunity for LNG developers and operators to improve the economic viability of their projects and reduce costs across the supply chain. Harnessing digitalization to its fullest potential requires careful upfront planning in the form of a digital roadmap to identify long-term opportunities and to ensure cost-effective implementation and cyber security from the earliest stages of development.

Recommendations. A great deal of money, effort and resources are spent on design and development, regulatory approvals, financing and negotiating offtake agreements.

Owners and developers must consider numerous factors to reduce costs, including location, gas supply, power source, transportation/shipping method, etc. For project owners and developers, evaluating every option is critical to achieving the greatest return on investment. Many commercial and operational benefits can be realized by partnering with OEMs in the early development phases to achieve a cost-optimized solution that spans the entire LNG value chain. GP

Literature cited

- Russell, M., “A question of scale,” LNG Industry, August 2018.

- International Gas Union, “World LNG Report,” 2017, online: https://www.igu.org/sites/default/files/103419-World_IGU_Report_no%20crops.pdf

- Barden, P., “Optimize LNG liquefaction operations through proper refrigeration compressor driver selection,” Siemens AG, 2016.

- Bailie, B. and M. Russell, “How APM in LNG operations can lower TCO and boost ROI,” Hydrocarbon Processing, July 2018.

|

Matthew T. Russell is Executive Vice President of LNG for Siemens’ global LNG portfolio. Prior to this role, he served as Vice President of Gas to Power. Mr. Russell joined Siemens in 2017 following a 10-yr career at KBR, where he served as Director of Business Development, based in Saudi Arabia. Mr. Russell began his career in the energy industry in 2003 as a Project Engineer with MACTEC (now AMEC). He earned a BS degree in civil engineering from Ohio State University in 2003 and an MBA degree from the University of Delaware in 2007.

|

Jennifer Adams is the Manager of Siemens’ LNG Engineering and Technology Group. She has more than 20 yr of industrial experience in research and development, process design and engineering. Mrs. Adams specializes in LNG and LNG technology, providing expert assistance and advice regarding risk management, plant design, operations, troubleshooting and optimization. She holds a BEng degree from Texas A&M University in College Station, Texas and is a registered Professional Engineer in Texas.

Comments