New products

Dynamic gas blending retrofit kit for well stimulation applications

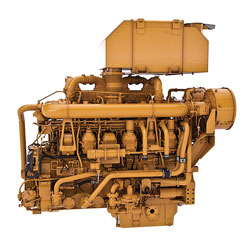

Caterpillar Global Petroleum’s dynamic gas blending (DGB) retrofit kit, for the Cat 3512C (HD) engine used in well stimulation applications, can substitute diesel with natural gas (NG), compressed natural gas (CNG), liquefied natural gas (LNG) and field gas with a lower heating value between 850 Btu and 1,250 Btu. The kit can exchange diesel with NG during high-pressure pumping operations, and it is available in both air-to-air-after-cooled (ATAAC) and separate-circuit-after-cooled (SCAC) configurations for 2,250 hp and 2,500 hp at 1,900 rpm ratings.

Fully integrated with the engine control system, the DGB kit can be installed on existing engines. The kit’s combined muffler and Cat diesel oxidation catalyst (DOC) enables engine compliance to US Environmental Protection Agency (EPA) Tier 2-level emissions. It also eliminates the need to integrate a Cat DOC with existing mufflers, and a single-engine control unit simplifies the electrical system.

System tracks crude oil deliveries in real time

The TouchStar CrudePac automated electronic ticketing and invoicing system, developed specifically for crude oil and water-hauling applications, has been selected by Great Northern Midstream LLC to precisely track production deliveries of crude oil in real time. Partnering with Lunderby Trucking of Sidney, Montana, Great Northern transports thousands of barrels of oil a day via a mix of trucks, trains and pipelines.

The newly installed TouchStar CrudePac system for Great Northern is in its pilot stage.

Great Northern Midstream’s management is planning to expand the system fleet-wide.

ABB gains more gas measurement solutions

With the acquisition of Los Gatos Research (LGR) of Mountain View, California, ABB has added a new line of high-performance gas analyzers to its measurement business. According to ABB, LGR brings new solutions to clients in the oil and gas production, combustion emissions and other industries.

LGR provides analyzers and services for measuring trace gases and isotopes in real time for research and environmental monitoring. Its analyzer technology, based on off-axis integrated cavity output spectroscopy (OA-ICOS), is said to have a higher sensitivity, precision and accuracy than traditional sampling and laser-based technologies.

Variable-area flowmeter delivers supreme performance in extreme conditions

Brooks Instrument’s MT3809 armored variable-area (VA) flowmeter is claimed to perform effectively in extreme conditions in chemicals, petrochemicals, oil and gas, and liquid petroleum gas (LPG) applications. It works accurately across a range of operating temperatures—from –196°C to +420°C (–320°F to +780°F)—and at pressures up to 1,380 bar (20K psi). Even in demanding applications, the MT3809 delivers 2% full-scale/1.6 VDI accuracy.

The explosion-proof housing meets the most stringent hazardous-area classifications worldwide, and a flameproof option is available for IIC/Class 1 Division 1 locations.

The MT3809 VA flowmeter is not limited by application, process configuration or flowrate. It can help simplify design and maintenance and be installed quickly and easily. The flowmeter’s rugged stainless steel construction and weld-neck flanges provide long-term durability in all configurations. No back pressure is needed for gas applications, and ASME sealing specifications are met with a standard gasket.

www.brooksinstrument.com/mt3809

Dresser-Rand dry gas seals extend oil life

Dresser-Rand dry gas seals are installed on 95% of new compressors for varied services throughout the world. The seals’ advanced designs and state-of-the-art manufacturing and testing offer a full-service seal solution for existing centrifugal compressors.

Dry gas seals are said to eliminate the need for complex and costly seal oil systems and the ongoing maintenance associated with them. The seals also improve efficiency by ousting the parasitic power losses caused by oil shear and drag, and by eliminating contamination of process gas by seal lubricants.

Meter measures LNG at cryogenic temperatures

Measuring liquefied natural gas (LNG) volume using Emerson Process Management’s Daniel 3818 ultrasonic meter reportedly delivers higher accuracy than static measurement methods. The flowmeter’s multiplane British Gas design, fast signal processing and advanced transducer technology provide a factory-proven linearity within +/–0.15% and a meter factor uncertainty of +/–0.027%. Using two independent transmitters (one for each set of four chordal paths) ensures complete measurement redundancy and the ability to poll each four-path meter separately. Specialized electronics provide stable ultrasonic signals and optimal low-flow response.

Daniel 3818 flowmeters withstand product temperatures ranging from –196°C to +60°C

(–385°F to +140°F). They are full-bore meters with no internal moving parts to wear or drift, providing for low pressure drop and minimizing LNG flashing risk.

Modular frac manifolds offer benefits for shale gas field operators

Skid-mounted modular frac manifolds, now available from GE Oil and Gas’ Pressure Control business, are said to safely allow simultaneous frac operations on multiple well pads. Each self-contained unit’s customized array of actuated valves, blocks and frac head outlets safely isolate each well during stimulation. Multiple manifolds can be installed side by side to accommodate specific wellsite requirements.

Other benefits include:

- A unique hydraulic jacking system to move units together for assembly, enabling quicker and safer installation

- An ergonomic handwheel at stand level within the safety zone to minimize restrictive movements

- Unit-connecting spools with a rotating flange for adjustability

- A double-acting hydraulic actuator with manual override to ensure proper flow control and shutoff

- Self-contained units that act as barriers to hold fluids and assist in preventing environmental issues.

High-efficiency technology for the LNG industry

Dresser-Rand has a worldwide exclusive license to Expansion Energy’s proprietary VX Cycle technology. VX Cycle is believed to be the first technology to provide a cost-effective, small-scale liquefied natural gas (LNG) production process with capacities as low as 1,500 gallons per day.

The technology’s mobile, skid-mounted equipment configuration opens up various applications in markets presently underserved or not served at all. Applications include the monetization of flared gas/associated gas; production of stranded natural gas fields that are not close to existing pipeline infrastructure; onsite fuel supply for drilling rigs converted to run on LNG; and production of vehicle-grade LNG, allowing LNG to compete effectively with diesel fuel.

Steam reforming technology turns oil production gas into energy

With steam reforming technology, the Wärtsilä GasReformer converts gases produced during oil production, which are abundant in heavy hydrocarbons, into a methane-rich product for use in Wärtsilä dual-fuel engines operating at full performance levels. Such gases would typically be flared and wasted.

While catalytic conversion of hydrocarbon feeds to hydrogen is a known process, the Wärtsilä GasReformer is said to represent a totally new application under very different conditions than those of the traditional process. The GasReformer is unique in its ability to convert unwanted heavier fractions from the gas into methane. By turning otherwise waste gas into fuel, the system lowers operating costs while enhancing environmental sustainability.

The Wärtsilä GasReformer was awarded the Offshore Technology Conference (OTC) 2013 Spotlight on New Technology Award.

Controller for oil, gas and hydrocarbon processing applications

The Fisher L2e level controller is said to bring fully electric level control to applications in oil and gas production, compression and hydrocarbon processing systems. Using a rugged, force-balanced displacer sensor, the controller detects the level of a single liquid or the interface of two liquids.

A fully electric level control loop eliminates emissions and increases uptime. Also, the control loop reportedly requires less maintenance

than conventional pneumatic level loops.

L2e zero and span adjustments enable tuning for various level loop applications. Additionally, the controller is certified for use in hazardous areas and is NACE-compliant for sour service.

Comments