Canned sealless pumps for hazardous applications

The oil and gas industry has many applications that are toxic or hazardous, where process fluid leakage is not permitted and leads to health, safety and environmental impacts. Caustic/acidic applications, high benzene concentrations, hydrogen sulfide-rich oil/gas and liquids operating above their auto-ignition temperatures are examples of such liquids that pose a risk to operations. For these types of hazards, special arrangements must be in place to ensure a safe operating environment.

Pumps in the industry require special attention, especially in the interface between the fluid and the environment where potential leakages can happen. Mechanical seals are used to contain fluid within equipment; however, the costs for such seals continue to increase—this includes maintenance, design and operating requirements. Currently, several alternatives to traditional seals are being employed, such as sealless systems, which are hermitically sealed from atmosphere and do not require sealing. This technology is considered relatively new and requires more studies to understand the limitations and factors associated with its operation. These studies, which include financial and maintenance factors and design limitations, should be implemented to gain a mature and reliable technical solution that is available to end users.

Pump systems. Since they are the prime movers of fluids, pumps are considered the heart of oil and gas plants. Pumps continue to develop, with several technologies emerging for multiple applications designed to solve industrial problems. One of these challenges is sealing against atmosphere, which comes prevalent for hazardous applications. With today’s advancements, multiple solutions exist, such as mechanical seals and sealless pumps.

In this article, the authors will focus on the limitations and considerations for canned sealless pumps vs. sealed pumps for hazardous applications. This work draws upon the vast knowledge and experience captured within Saudi Aramco operating facilities and details the positives and negatives of each pump type. The limitations were studied in terms of the following factors:

- Financial

- Maintenance

- Design and limitations

- Operation experience.

The evolution of sealless pumps. The development of the sealless pump—led by the nuclear energy industry—was driven by the need for a hermetically sealed option. Sealless pumps are governed by API 685, ASME B73.3 and ISO 15783. These governing standards do not cover all aspects of design and still require more input from the technical community to be a reliable solution for all hazardous services. It is worth mentioning that the referred standards emerged during the early 2000s. When comparing this to the well-established API 610 standard (established in the 1950s), it is apparent that the sealless pump industry has a long advancement path ahead. It is important to note that the sealless pump has been utilized since the early 1900’s, although it lacked the oversight of a governing standard that is populated by community experience.

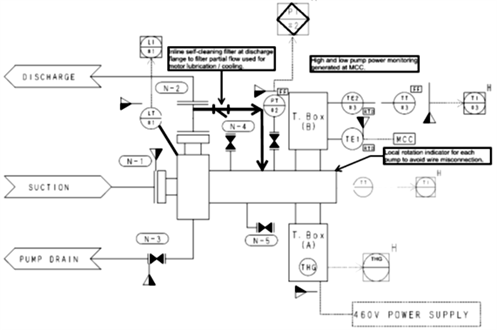

Canned sealless pumps. This pump includes a close-coupled motor and a pump within the same casing, equipped with an end suction and overhung impeller (FIG. 1). The pump’s rotor assembly is enclosed within a pressure vessel within the pumped fluid. This pressure vessel is also known as “primary containment.” It is sealed by static seals such as O-rings or gaskets.

|

|

FIG. 1. The anatomy of a canned sealles pump. Source: Nikkiso Co., Ltd. |

Hazardous applications sealing solutions. The API 682 Standard—Shaft Sealing Systems for Centrifugal and Rotary Pumps—provides solutions to seal pumps’ process side against environment. Dual-pressurized and non-pressurized seals are the ultimate method to seal a centrifugal pump, with nearly no fluid escaping to atmosphere. A range of seals is defined in the referenced standard, matching specific process requirements. API Plan 75 and 76, when joined with any seal flushing piping such as Plan 52, 53 and 54, are all accepted candidates for sealing. Each of these specified seals has a specific consideration. For example, Plan 52 is less tolerant to dirty, abrasive or polymerizing products.

WHAT TYPE OF PUMP TO USE?

Hazardous and toxic services require special attention in the design of oil and gas plants. From a design perspective and during the grassroots development of the Tanajib Gas Plant, the authors’ company always questioned what type of pump should be utilized for a given hazardous service? The authors’ company wanted to capitalize on state-of-the-art technology and incorporate it into the plant’s design. The canned sealless pump offered a great candidate for most of the plant’s applications; however, there was no clear criteria to follow to distinguish where the reliable solution would be a sealless pump or a sealed pump with either pressurized or non-pressurized seals.

After thorough investigations, sealless canned pumps were chosen. The following criteria on this choice was based on the differences between sealless pumps and API seal plans.

Financial factors. The following are some of the financial factors that were considered on the selection of canned sealless pumps for the Tanajib Gas Plant.

Initial cost (capital expenditure). The canned sealless pump, intrinsically, has less components and manufacturing requirements. The cost of the seal, shaft hubs, couplings and auxiliary piping was more economical and cost-effective. The cost deduction from the capital expenditure (CAPEX) is compensated by the maintenance difficulty, as canned sealless pumps cannot be maintained in-situ since they are filled with hazardous liquids. This mandates that an offline spare pump replacement must be considered for storage as a best practice to minimize system downtime and production loss. This cost is a hidden cost that is not obvious.

Another financial factor considered was the reduced installation costs of canned sealless pumps. The integral design minimizes the fieldwork of piping alignment vs. the sealed-type pump where the motor and pump installation are difficult (in terms of field worker hours).

Preventive maintenance for pumps and sub-systems. Canned sealless pumps require minimal mechanical preventive maintenance and have nearly no sub-systems vs. sealed centrifugal pumps. The maintenance is limited to a vibration audit, visual inspections, instrumentation calibration and verification. Canned sealless pumps do not require lube oil for operation; therefore, no daily routine checks are required by operators. In comparison to sealed pumps, sealless pumps are considered as “run to fail” equipment. Literature indicates that a sealless canned motor pump can achieve a lifecycle of 10 yr–12 yr of mean time between failure (MTBF) if they are properly selected, operated and installed.

Protection instrumentation and controls. The protection system required for canned sealless pumps is different vs. traditional sealed pumps. The requirements governing the protection instrumentation are different, depending on the standard—e.g., API 685-designed pumps require more instrumentation vs. ASME B73.3-designed pumps. For this article, the authors will focus on API 685 requirements due to the use in oil and gas applications. Maintaining flow through is crucial for canned seallless pumps since they are used for internal cooling. The canned sealless pump is like any pump that is subjected to dry running since these pumps are designed to be self-lubricating, with no alternative methods to remove heat, but utilizing the process fluid as a lubricant. This necessitates additional protection measures and monitoring for the rotor/stator and bearings/bushings. Based on the criticality for canned motor pumps, the following instrumentation (FIG. 2) is recommended:

|

|

FIG. 2. Canned sealless pump’s instrumentation. |

- A level sensor to measure liquid inside the canned casing to prevent pumps running dry

- A temperature sensor on the motor stator windings should be set for alarm/shutdown in case loss of cooling fluid circulation or overload

- A power sensor on motor wiring set for alarm/shutdown for excessive load

- A pressure sensor on secondary pressure casing set to shutdown in case of rising pressure due to a containment shell leak

- A shaft position sensor (radial or axial) to be set to alarm/shutdown, depending on the pump’s size, power or criticality

- A vibration sensor on the pump’s bearing housing (accelerometer) set to alarm/shutdown.

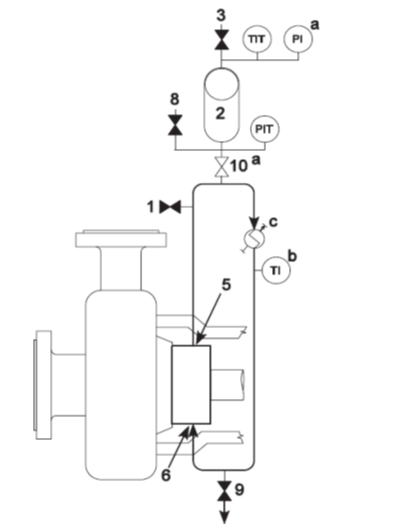

The monitoring and protection systems required for a canned sealless pump are comparable to a sealed centrifugal pump (FIG. 2). In comparison, the most demanding type of seals are pressurized arrangement 3 API plan seal types 53 or 54 where the pump requires less instrumentations. For example, Plan 53B (FIG. 3) shows that the pump seal requires only a temperature transmitter and a pressure transmitter.

|

|

FIG. 3. API 682 Plan 53B. Source: API. |

Regarding the pump itself, API 610 requires an additional vibration measurement, depending on the size and criticality of the pump. In addition, as auxiliary equipment, Plan 53B requires a pressurized accumulator and cooler, depending on the arrangement.

The CAPEX and operating expenditures (OPEX) for instrumentation required by the canned sealless pump are much higher—it requires additional wiring, switches, transmitters underground connections and an ESD interface, among others. These instrumentation implications should be considered when specifying a canned sealless pump as a candidate for any hazardous service.

Utilities requirements. API 682 seals for hazardous applications usually require a pressurized barrier liquids reservoir to supply clean fluid for an arrangement 3 pressurized dual seal. These liquids add significant operating cost, as they are required throughout the lifecycle of the equipment. These liquids can be water, process liquids, oil or any different type that is chemically compatible with the process and does not introduce cross contamination or degradation of the final product. The designer must keep in mind the scarcity of such a utility. One example can be the utilization of water, where it is not economically nor an environmentally smart decision to be utilized in a desert or remote areas. Another example is the utilization of oil, where the logistics of transportation and storage should be taken into consideration. Canned sealless pumps are designed to be hermetic and do not require any pressurized buffer or barrier liquid to seal against atmosphere. This is an attractive solution which minimizes site activities and maintenance/top up activities performed by operators.

Lubrication requirements. Canned sealless pumps are self-lubricating and utilize the process fluid to cool the internal parts. The requirement of lube oil and an auxiliary lube oil system is not applicable to canned sealless pumps, regardless of power rating. This should be taken into consideration when thinking about the OPEX implications while designing for sustainability. This has a positive environmental impact, as oil disposal and storage pose an environmental hazard and require special considerations and procedures.

Footprint and baseplate design. Canned sealless pumps offer a compact design vs. standard sealed pumps. The exclusion of the seal system and affiliated piping significantly reduces the footprint and materials for construction. Manufacturing, machining costs and total materials costs are reduced, along with required grouting. The specialized machining/leveling required for foot pads is less than those required for conventional API 610 pumps since canned sealless pumps requires only four pads for installation vs. eight pads. These benefits contribute to a lower overall baseplate price; and efficient spacing can be achieved with sealless pumps.

Repair costs. Repair cost for canned sealless pumps must be taken into consideration while designing a plant. The vendor takes full responsibility of the maintenance, specifically the overhaul process. The turnaround time for these pumps can be as much as 2 mos. In Saudi Arabia, there are no licensed maintenance facility for these canned sealless pumps. The designer should bear in mind the costs associated with each maintenance and add them to the total lifecycle cost. This cost includes shipping, customs, clearances, packaging and other miscellaneous expenses.

In comparison, traditional API 610 pumps can have a turnaround of 2 d to 3 wk, depending on the design complexity and size. Furthermore, Saudi Arabia has multiple vendors with maintenance capabilities that can cater to both onsite and at-shop maintenance. These costs increase OPEX of canned sealless pumps; however, depending on the application and the availability of local maintenance facilities, these OPEX can be justifiable. Designers and plant owners should investigate the associated cost and turnaround time and factor these into their selection criteria.

Testing and inspections for pumps and mechanical seals. The testing of mechanical seals adds additional CAPEX to sealed pumps. API 610 pumps studied here are pressurized seals, which are expected to provide a high level of protection due to the nature of the process duty. API 682 dictates several tests for high-fidelity seals, such as hydrostatic testing, functionality testing, etc. These tests add to the price of conventional pumps, which are not required for sealless pumps.

Auxiliary piping. To compare sealed pumps with canned sealless pumps, it is apparent that a seal requires more auxiliary piping. API 682 requires the piping to be stainless steel, with welded joints, class 800 valves and a specific wall thicknesses. This piping adds to the total cost of the pump.

With canned sealless pumps, there are two cases where auxiliary piping is required: flushing/cleaning and cooling. Flushing and cooling lines are designed to provide clean and cooled process liquid to the rotor—different configurations are identified in API 685 Annex D. The auxiliary piping quantity required for canned sealless pumps is less than the ones required for sealed pumps. This reduces the financial impact of piping and contributes to a reduced cost. GP

REFERENCES

- API, “API 682, 4th Ed.: “Pumps—Shaft Sealing Systems for Centrifugal and Rotary Pumps,” API, Washington, D.C., 2014.

- API, “API 610, 11th Ed.: “Centrifugal Pumps for Petroleum, Petrochemical and Natural Gas Industries,” API, Washington, D.C., 2011.

- ASME B73.3, “Specification for Sealless Horizontal End Suction Centrifugal Pumps for Chemical Process,” ASME, New York, 2015.

- ISO 15783:2002, 1st Ed., “SEAL-LESS Rotodynamic Pumps—Class II—Specification,” ISO, Vernier, Geneva, Switzerland, 2002.

- Hernandez, T. “A Users Engineering Review of Sealless Pump Design Limitations and Features,” International Pump Users Symposium, 1991, online: https://oaktrust.library.tamu.edu/bitstream/handle/1969.1/164247/P8129-145.pdf?sequence=1&isAllowed=y

- Alkhowaiter, A., “Extreme Reliability: Achieving Zero Maintenance with Hermetic Centrifugal Pumping Applications,” 2020.

- Mulholland, R., “Maximizing Reliability in Sealless Pump Operation,” Pumps & Systems, 2001.

|

Abdulrahman Al-Sultan is Gas Turbine and Diesel Engine committee member in Saudi Aramco. He joined Aramco in 2015. He earned an MBA in engineering science from the University of Wisconsin Milwaukee.

|

Shuja Alharbi works at Saudi Aramco. He is a certified PMP with more than 14 yr of experience in the oil and gas industry, turbomachinery and static equipment. He earned a BSc degree in mechanical engineering.

Comments