Ju`aymah NGL fractionation energy optimization initiatives

Wasting energy reduces plant profitability and its sustainability footprint. With increasing energy costs and environmental impact, energy efficiency is becoming more important than ever. To be aligned with these requirements, an energy optimization program launched in 2017 as well as several in-house initiatives were implemented to optimize the processes for the reduction of energy consumption.

Three major initiatives implemented at an NGL fractionation plant are outlined here, including steam reserve optimization, Adip propane trim heaters shutdown and an automating LPG dehydration regeneration cycle. Implementing these energy saving initiatives successfully reduced approximately 296 MMBtu/hr of energy, lowered operating cost, improved plant energy intensity key performance indicators (KPIs) (EII) by approximately 8.5%, and increased equipment life and reliability.

The energy intensity index (EII) is an index of energy intensity that compares the consumption of primary energy sources at a plant with benchmarks of a similar complex, measuring energy performance. It is worth highlighting that all of the initiatives were implemented without major process modification or capital expenditures.

Process background. There are four identical fractionation modules (trains): each module consists of de-ethanizer (De-C2), depropanizer (De-C3) and debutanizer (De-C4) columns; an amine treating facility (Adip unit) to remove hydrogen sulfide (H2S) and carbonyl sulfide (COS) from C3 product received from De-C3 overhead; and mercaptan oxidation (merox) processing units for mercaptan sulfur removal from C3 and C4 products, followed by the C3 and C4 dehydration system for moisture removal from the final product. A common utility area supplies plant chemicals, boiler feed water and steam. The plant’s steam demand is met by three cogeneration units and several high-pressure (HP) boilers. The following sections detail all three energy optimization initiatives.

Steam reserve optimization. The plant’s steam demand is met by three cogeneration units and several HP boilers. The total steam demand fluctuates heavily due to significant changes in the feed rate. To meet the steam demand and avoid any adverse operational impact during sudden cogeneration unit or boiler trip, more than the net required number of boilers were always operated. The availability of additional steam production capacity by maintaining the extra number of boilers in operation is defined as steam reserve. Historically, more than 1.1 MMlb/hr (million pounds per hour) of steam reserve was maintained; to maintain a greater steam reserve than net steam demand, additional boilers were forced to operate at a minimum maximum continuous rating (MCR), which is close to 30%. Operating boilers at a minimum MCR is inefficient and results in significant energy wastage.

The objective of this study was to re-evaluate and optimize the steam reserve strategy to improve plant EII and reduce operating costs.

Historically, the steam reserve supported plant operations during cogeneration unit or boiler trips and maintained plant processing capacity. Due to feed fluctuations, cogeneration plant and boilers reliability, associated risks and potential financial losses with no steam reserve, it was concluded that maintaining zero steam reserve is impractical for operation. During any trip of steam-producing facilities, the available steam reserve from the boilers helped maintain plant processing capacity that avoided any large impact on customer supply. It is worth mentioning that it takes approximately 8 hr to start a new boiler should the need arise, while steam production can be ramped up by 10%/min in an operating boiler.

As an alternate approach, standard deviations in the feed fluctuation for the last several years were calculated to estimate steam demand and the steam reserve required to handle feed fluctuations. Sudden cogeneration unit and boiler trips were also considered for establishing a new steam reserve strategy. Analyzing all operating parameters in detail, the plant’s team recommended maintaining a steam reserve between 350,000 lb/hr and 650,000 lb/hr (equivalent to one Cogen capacity) to reduce fuel gas consumption, increase financial benefits and improve plant EII KPI.

The recommended steam reserve was sufficient to handle feed fluctuations and plant processing capacity during one cogeneration or boiler trip. Lowering the steam reserve from 1.1 MMlb/hr to the recommended level reduced boiler fuel gas consumption; increased boiler loads close to the MCR limit and enhanced boiler efficiency; eliminated excessive steam venting, which saved both energy and water; and reduced the load on excess steam condensers. The new steam reserve and boiler operation strategy reduced boiler startup/shutdown frequency, which reduced boiler maintenance costs and enhanced boiler life span.

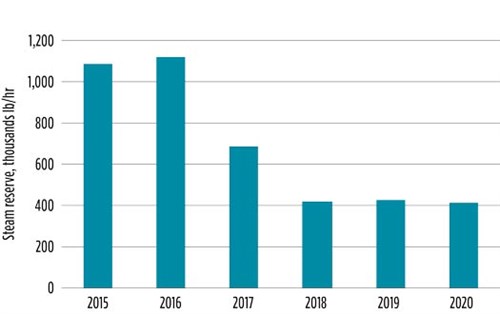

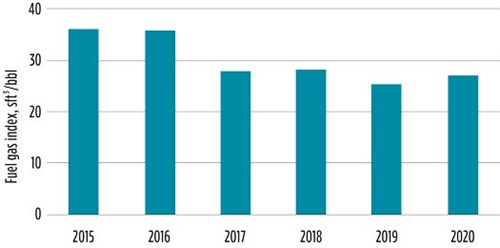

FIGS. 1 and 2 demonstrate the reduction in boiler steam reserve and improvement in plant fuel gas index, respectively. The actual steam reserve reduced from 1.1 MMlb/hr from 2015–2016 to an average of 490,000 lb/hr from 2017–2020. It is worth mentioning that this subject strategy was implemented during the middle of 2017, so from 2018–2020 the average steam reserve was maintained at 423,000 lb/hr. Similarly, due to the reduction in the steam reserve, the fuel gas index reduced from 36 sft3/bbl (2015–2016 average) to 27 sft3/bbl (2017–2020 average).

|

|

FIG. 1. Steam reserve trend. |

|

| FIG. 2. Fuel gas index trend. |

Maintaining steam reserve between 350,000 lb/hr and 650,000 lb/hr resulted in a savings of 242 MMBtu/hr of energy due to the increase in boiler MCR and efficiency. This lowered fuel gas consumption, eliminated steam venting and reduced excess steam condenser load.

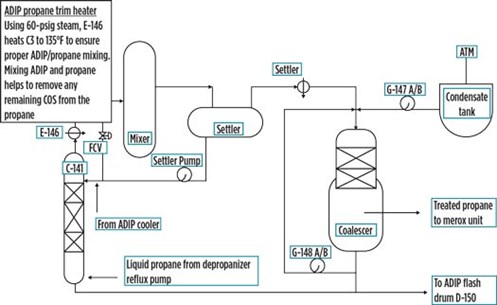

Adip propane trim heater shutdown. The purpose of the Adip unit is to remove H2S and COS contaminants from C3 hydrocarbon streams produced from the depropanizer column overhead to meet product and environmental performance specifications. The Adip unit must also be operated in such a way as to provide efficient operation of downstream treating units: merox and molecular sieve dryers. The objective of the Adip propane trim heater is to increase propane temperature downstream of the extractor and before the mixer settler configuration in all modules. Using 60-psig steam, the Adip propane trim heater heats C3 to 135°F to ensure proper ADIP/propane mixing. Mixing ADIP and propane helps to remove any remaining COS from the propane product after the extractor in the mixer settler configuration. An Adip propane process configuration is shown in FIG. 3.

|

| FIG. 3. Adip treating overview. |

An assessment was completed to check if Adip propane trim heaters in all modules can be shut down to save energy without impacting the product sulfur specifications. A field test was conducted by bypassing the Adip propane trim heater in Module 1 and 3 for almost 1 yr to span an entire winter and summer. During this shutdown, periodic lab results were analyzed for H2S and COS removal impact and to determine any impact on the net product sulfur specifications. The long period data analysis revealed no sulfur removal impact due to the subject heater bypass, and total product sulfur, H2S and COS from the Adip unit during both summer and winter periods remained intact.

Based on the test results, it was decided to shut down and mothball the Adip propane trim heaters in all modules. One reason the product sulfur specification was not impacted as a result of the trim heater bypass was that the plant receives significantly less acid gas (H2S and COS) along with feed compared with the design value. This was confirmed by comparing the design and actual acid gas loading based on feed composition analysis and the actual acid gas flaring flowrate vs. its design value. Therefore, bypassing the subject heater had no impact on meeting the product sulfur specifications.

Shutting down the propane trim headers resulted in a total steam savings of 50,400 lb/hr of energy, or 45 MMBtu/hr. Additionally, shutting down the subject heaters resulted in a ~1.5 % reduction in the overall plant EII.

LPG dehydration system regeneration cycle automation. During a routine LPG dehydration unit breakthrough test, it was noticed that the fractionation modules dehydrators heating cycle duration was fixed at 11 hr, while the required duration varies depending on the molecular sieves’ performance and condition.

As per industry best practices and desiccant supplier/vendor recommendations, regeneration heating should be completed once the temperature difference between the vessel inlet and outlet stabilizes at 27°F–36°F over a period of 45 min–60 min. Therefore, it was recommended to automate the heating cycle duration to be linked with the inlet and outlet temperature differences to achieve the optimum heating cycle duration to avoid overheating the molecular sieves and conserve energy. This brings an estimated steam savings of 9,500 lb/hr, or 9 MMBtu/hr.

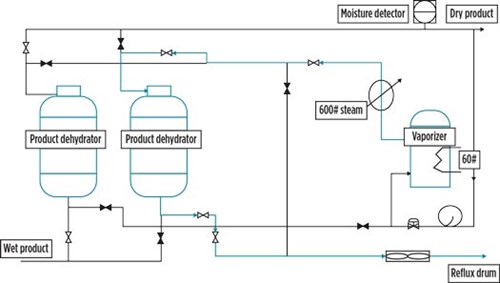

Molecular sieve process description. At any given time, one of the dehydrators will be adsorbing water from the feed, while the other will be in the process of being heated or cooled to regenerate the desiccant online mode. Initially, wet product passes through the operating dehydrator, then is dried and pumped to the refrigeration, storage and/or export areas of the plant, as shown in FIG. 4.

|

| FIG. 4. LPG molecular sieve process. |

The bed is switched to the regeneration cycle after being saturated with water. In this mode, a slipstream of dried product liquid is recycled to regenerate the molecular-sieve beds. The recycled liquid is vaporized with low-pressure stream, superheated to temperatures of 460°F with a high-pressure steam, and then routed to the wet tower to remove the previously adsorbed water.

As the temperature within the tower increases, the water captured within the pores of the desiccant turns to steam and is absorbed by the regenerated gas. This gas leaves the bottom of the tower and is cooled by an air-cooled condenser. When the gas is cooled, the saturation level of the water vapor is lowered significantly and water is condensed. The condensed liquid is recycled to the appropriate upstream reflux drum.

The heating cycle last approximately 11 hr. When the heating cycle is completed and the bed has been dried, a cold recycle liquid is passed in an up-flow arrangement through the tower to return it to normal operating temperatures (about 100°F–120°F) before placing it back into service to dehydrate the wet feed stream. The cooling cycle takes approximately 4 hr.

Breakthrough test results for Modules 1 and 2 showed that the fixed duration of the heating cycle is much higher than required. It was noticed that the required regeneration cycle duration is much less than the existing fixed time where the molecular sieves are exposed to overheating and energy is wasted. The average additional heating time was calculated to be 4 hr.

Therefore, it was decided that the regeneration heating cycle duration for all fractionation modules should be connected to the bed top and bottom temperature difference to optimize the regeneration cycle. As part of this initiative, the regeneration cycle logic was modified and linked with the bed top and bottoms temperature difference. Once the temperature difference reaches 30°F, the heating cycle should be stopped after 45 min. This logic modification was carried out in one of the module’s C3 dehydration systems; after closely monitoring all operating parameters for 6 mos, the same logic modification was implemented in all of the module’s C3 and C4 dehydration cycles. During the testing period, the bed temperature profile and time interval between consequent absorption cycles were closely monitored to ensure no adverse impact on bed performance due to subject modifications.

Implementing the aforementioned recommendation led to a savings of 9,500 lb/hr of steam, or 9 MMBtu/hr of energy, and enhanced the molecular sieves life by approximately 15%–20% by avoiding unnecessary overheating.

Takeaway. The successful implementation of several in-house energy optimization initiatives resulted in 296 MMBtu/hr of energy savings, reduced plant operating cost, improved EII, and lowered nitrogen oxide (NOx) and sulfide oxide (SOx) emissions. These results could not have been achieved without collaborative efforts by operations, engineering and maintenance teams. GP

|

PUKHRAJ GARG has worked as Lead Process Engineer with Saudi Aramco`s Ju’aymah NGL fractionation plant since 2012. He is a certified PE Engineer with more than 17 yr of experience in the oil and gas industry. He previously worked with Reliance Industries, UOP and Dupont as a process engineer. Mr. Pukhraj holds BS and MS degrees in chemical engineering from Indian Institute of Technology (IIT) Bombay, Mumbai, India and an Executive Post Graduate Diploma in capital and finance from Indian Institute of Foreign Trade (IIFT), New Delhi, India.

|

NAWAF M. MENAIKHRR has worked as Inspection Unit Supervisor with Saudi Aramco’s Ju’aymah NGL fractionation plant since 2015. He has also worked as a process engineer in several NGL plants. Mr. Nawaf holds a BS degree in mechanical engineering from King Saud University, Riyadh, Saudi Arabia.

Comments