New in Gas Processing Technology

Wärtsilä, Vantaa Energy cooperate on a synthetic biogas project

|

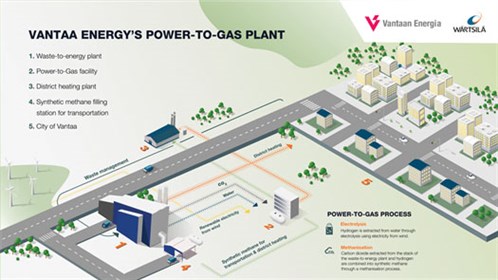

Finnish technology group Wärtsilä and Finnish energy company Vantaa Energy Ltd. have signed a cooperation agreement for pre-engineering and development of a power-to-gas (P2G) plant for Vantaa Energy. The plant, planned to be commissioned in 2025, would be the largest in Finland and also the first to produce carbon-neutral, synthetic methane on a commercial scale with a fuel capacity of 10 MW.

Synthetic methane is produced from captured CO2 and H2 produced with renewable energy. The companies intend to continue joint development of the project toward a commercial-scale pilot project. Synthetic biogas would replace the use of conventional natural gas in district heating, thereby reducing Vantaa Energy’s CO2 emissions. Wärtsilä will contribute its know-how in power-to-gas processes and technologies, while Vantaa Energy will bring its experience and understanding of the district heating business and project-specific requirements.

In-Field Flow Coating increases pipeline flow capacity by 20+%

Rescue Pipeline Services LLC’s In-Field Flow Coating (IFC) technology for existing gas pipelines significantly increases efficiency and performance of existing (in-place) pipelines. The specially formulated, advanced “nano” composite coating utilizes small molecular structures that coat microscopic nooks and crannies in a way that is not possible with conventional coatings.

The unique nano properties, combined with expert in-situ pipeline application, result in an ultra-slick, low-friction and abrasion-resistant surface, providing lower friction loss, increased flow, lower energy consumption and reduced deposition of debris and contaminates, with minimal surface preparation. By reducing the surface roughness, the coated surface reduces the friction factor of the pipe wall, reducing pressure loss and increasing pipeline capacity.

The IFC system can make a significant difference in reducing compression costs and lowering greenhouse gas emissions. The IFC technology can be applied on long pipeline segments, of any diameter, by accessing only the ends of the pipeline.

Symbio Infrastructure plans world’s first carbon-neutral LNG facility

Symbio Infrastructure and Siemens Energy have entered into an agreement whereby Siemens Energy will provide engineering services, comprehensive lifecycle equipment and technology solutions, and further carbon emissions footprint reduction solutions for Symbio subsidiary GNL Quebec’s carbon-neutral Énergie Saguenay LNG project in Quebec. Siemens will also provide solutions for Symbio subsidiary Gazoduq’s carbon-neutral natural gas transmission line project between Ontario and Quebec.

Énergie Saguenay’s 10.5-MMtpy LNG export facility will be powered by nearby renewable hydroelectricity and is expected to set a global standard for carbon-neutral LNG production. Fed by Gazoduq’s carbon-neutral natural gas transmission line, Énergie Saguenay plans to operate the lowest-carbon-intensity LNG plant in the world.

Under the agreement, Siemens Energy will provide its portfolio of greener solutions for rotating equipment, electrical and digital infrastructure. The companies will also work together to explore green H2 development opportunities as a new potential investment initiative to be considered by Symbio. Siemens and Symbio envision the alliance aligning with the principles included in the March 2021 Energy Partnership between Germany and Canada to advance their respective net-zero aspirations.

Russia’s first LNG refueling ship completes trials

The country’s first ship designed to run on LNG and fuel other vessels with LNG has completed its sea trials, according to Gazprom Neft. The Dmitry Mendeleev is an Arc4 ice-class vessel that will be able to transport up to 5,800 m3 of LNG. It will operate in ports on the Gulf of Finland and in the Baltic Sea, including St. Petersburg, Ust-Luga and Primorsk. The vessel is expected to enter Gazprom Neft’s fleet in the second half of 2021.

Nacero develops energy transition infrastructure

Nacero has awarded Bechtel a FEED contract for the first large-scale natural gas-to-gasoline manufacturing facility in the U.S. Nacero’s 115,000-bpd plant in Penwell, Texas will be the first gasoline manufacturing plant in the world to incorporate carbon capture and sequestration (CCS) and 100% renewable power.

The use of renewable natural gas and mitigated flare gas will make it possible to reduce the lifecycle footprint of Nacero’s cost-competitive, zero-sulfur gasoline to zero over time. Nacero’s products will be sold to retailers in Texas and the Southwest region, and through Nacero-branded outlets.

Wärtsilä to supply largest bio-LNG plant

Wärtsilä will supply a biogas liquefaction plant to Norway-based Biokraft, a subsidiary of Scandinavian Biogas Group and a major player in the global biogas market. The 25-tpd plant will extend an existing bio-LNG production plant at Skogn in Norway, also supplied by Wärtsilä, to a combined total of 50 tpd, making it the largest facility of its kind in the world.

The market for liquefied biogas continues to expand along with the increase in global efforts to restrict the use of fossil fuels. Bio-LNG is an abundant renewable energy source that is used as “green” fuel in transportation, industrial and marine applications. The Wärtsilä mixed refrigerant technology and equipment are scheduled for delivery in May 2022.

Venture Global launches CCS projects

|

Venture Global LNG plans to capture and sequester carbon at its Calcasieu Pass and Plaquemines LNG facilities in Louisiana. Having concluded a comprehensive engineering and geotechnical analysis, the company intends to launch a shovel-ready carbon capture and sequestration (CCS) project, compressing CO2 at its sites and then transporting the CO2 and injecting it deep into subsurface saline aquifers, where it will be permanently stored.

Through this undertaking, Venture Global will capture and sequester an estimated 500,000 tpy of CO2 from its Calcasieu Pass and Plaquemines liquefaction sites. In addition, the company anticipates using similar infrastructure to capture and sequester 500,000 tpy of CO2 from the CP2 LNG facility, once permitted. Altogether, Venture Global plans to sequester 1 MMtpy of CO2, the equivalent of removing nearly 200,000 cars from the road each year for 20 yr. The successful deployment of CCS technology at Calcasieu Pass would be the first of its kind for an existing LNG facility in the U.S.

Uzbekistan to launch first GTL plant by late 2021

Operator Uzbekneftegaz will launch its first GTL plant in Q4 2021, helping Uzbekistan reduce its reliance on diesel and jet fuel imports. The $3.6-B plant will enable the country to use its large natural gas reserves to make diesel and other fuels. The plant will refine 3.6 Bm3y of gas and produce about 1.5 metric MMt of fuel.

Uzbekneftegaz GTL aims to produce approximately 307,000 tpy of jet fuel, 724,000 tpy of synthetic diesel, 437,000 tpy of synthetic naphtha and 53,000 tpy of LPG.

Axpo powers LNG ferry with biomethane

Spanish ferry operator Baleària’s LNG-powered ferry, Eleanor Roosevelt, has made a test crossing using renewable biomethane certified by Axpo Iberia. This is an important milestone for zero-emissions maritime shipping; for the first time in Europe, a high-speed ferry has made a test crossing using only fuel from 100% renewable sources.

The ferry, equipped with natural gas hybrid engines, completed the route of 133 nautical mi between Barcelona and Ciutadella (Balearic island of Menorca), using renewable biomethane. The use of biomethane as a renewable fuel on the test trip avoided more than 50 metric t of CO2 emissions.

Eleanor Roosevelt is a pioneering fast ferry and the seventh Baleària ship to use LNG. Each year, it is estimated to reduce CO2 emissions equivalent to eliminating more than 8,900 conventional passenger cars or planting around 27,000 trees.

Sempra Energy to advance net-zero energy systems

Sempra Energy has signed an MOU with the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL), providing a framework for a joint effort to advance future net-zero energy systems. The MOU, which builds on nearly 10 yr of ongoing collaboration, will continue current work in researching and developing innovative solutions to help shape a lower-carbon future through technology and applications capable of withstanding increasing energy demand and broad adoption while advancing future innovation.

Sempra Energy and NREL have been collaborating for nearly a decade on cooperative and multi-year projects exploring the development, access and integration of low-carbon fuels and microgrid technology. In 2013, Sempra Energy subsidiary San Diego Gas & Electric Co. (SDG&E) and NREL joined to establish the nation’s first utility-owned community microgrid in Borrego Springs, California, connected to a local 26-MW solar field, two battery storage systems, two generators and an ultracapacitor. The microgrid, which is being upgraded so that it can operate on 100% clean energy, was designed to provide consistent power flowing to the remote desert town during emergencies and planned outages on the larger grid.

In 2017, Sempra Energy subsidiary Southern California Gas Co. (SoCalGas) and NREL partnered to create, validate and integrate the first carbon-free, power-to-gas pilot system in the U.S. The technology takes excess electricity and converts it to H2, which can be used, stored or combined with CO2 and fed to a bioreactor to produce renewable natural gas (RNG). This technology could provide North America with a large-scale, cost-effective solution for storing excess energy produced from renewable sources. Additionally, Sempra Energy and NREL have coordinated efforts to research the impacts of H2 blending in natural gas networks.

Under the MOU, Sempra Energy and NREL will coordinate and share objectives focused on:

- Advancing artificial intelligence to scale solutions across the U.S. and enable cities to reach clean energy goals

- Integrating low-carbon fuel solutions, including H2, RNG, CCUS and fuel cells

- Exploring innovative solutions towards 100% renewable energy communities, requiring and implementing smart and enhanced controls, integration and operational capabilities as a blueprint for expansion

- Enhancing electric grids with technology that upgrades the infrastructure with a focus on reliability, connectivity and security

- Promoting viable net-zero solutions that are delivered with equity and widespread community access.

LNGC methane emissions study completed

Queen Mary University London, with support from the Collaboratory to Advance Methane Science (CAMS) and Enagas SA, successfully conducted a first-of-its-kind study to directly measure methane emissions of an operating LNG vessel. Results from the study will provide critical insights into the greenhouse gas profile of LNG carriers to identify opportunities for environmental performance improvement.

Researchers collected comprehensive direct measurements aboard the Cheniere-chartered newbuild GasLog Galveston during a round-trip voyage from Cheniere’s Corpus Christi liquefaction facility to a discharge port in Europe. Data gathered during the voyage included measurements of engine exhaust, as well as fugitive emissions. The results of the study are expected to be released in a peer-reviewed journal.

The project comes at a critical time, with policymakers seeking to understand both how to regulate industry and ensure that climate targets are met. The efforts undertaken by the CAMS are seen as essential to minimizing the environmental footprint of the global LNG shipping fleet and supporting the continued success and competitiveness of the LNG industry. GP

Comments