Streamline complex natural gas analysis for transport and custody transfer

It is fascinating to watch pipeline traffic these days, as enormous amounts of natural gas from a wide variety of fields routinely move across the gas supply chain. With fracking, biomethane and other new sources, the range of supply is wider than ever. Pipeline companies working on tight margins can take advantage of new opportunities by finding supplies at a lower cost. When this occurs, the chemical composition of what is delivered to end users can vary, changing its characteristics for fuel use on a daily basis. Gas producers, pipeline companies and even end users must monitor its composition to determine makeup, heat value and contaminants at multiple points in the supply chain to ensure that end users do not experience problems.

Required depth and detail for gas analysis varies significantly depending on the application. In some instances, it is simply a matter of verifying that the present supply meets the basic regulatory definition of commercial natural gas. Other supply sources may need more insight into the Wobbe Index, sulfur content, presence of higher hydrocarbons and various other parameters. For users at the more sophisticated end of the range, the analysis process can be complex and call for multiple technologies.

For example, if testing requires quantitative values of Btu content, hydrocarbon dewpoint, total sulfur and hydrogen sulfide, then four analyzers are often used. The importance of pairing the measurement of sulfur content with Btu content is growing due to evolving regulations and demands from end users, driving the need for analysis of multiple components.

It is no longer necessary to use multiple analyzers to make these and other measurements. Today’s analyzers, particularly gas chromatographs (GCs), have advanced in versatility and can now measure a much longer list of components than their predecessors, including sulfur.

Examining the gas mix. Natural gas is nominally methane, which typically accounts for around 80% of its volume. The balance can be made up of many kinds of products, including heavier hydrocarbons (up to C9+), non-combustible gases, low-heat-value combustible gases, and contaminants. Each of these components contributes to the Btu content of the mix, such as:

- Nitrogen and carbon dioxide add zero heating value and are simply ballast

- Hydrogen is lower than methane and pulls down the total heating value

- Heavier hydrocarbons are higher in Btu value than methane and boost the total heating value.

Determining the Btu content (i.e., heat value or calorific value) is the process of identifying all the components in the mix and totaling their individual values based on the proportion of each.

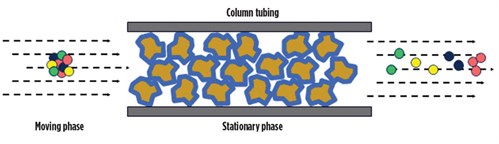

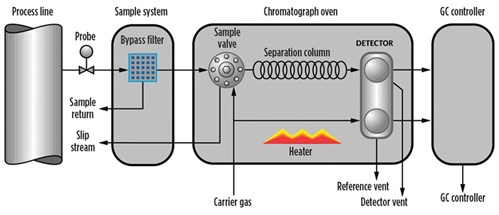

Gas chromatography: Separating the components. A GC is an analysis instrument for sorting and separating complex mixtures (FIG. 1). A natural gas sample is mixed with an inert carrier gas and moves through a packed column. During movement through the column, the components separate and exit the column in a prescribed order, allowing them to be identified and quantified by a thermal conductivity detector (TCD). The column and the TCD are inside an oven to maintain the required temperature (FIG. 2).

|

| FIG. 1. A GC pushes a mixed gas sample left to right, through a packed column designed to have varying affinity to the expected molecules in the sample. Each type of molecule spends a prescribed amount of time in the stationary phase, so the molecules leave in order, allowing them to be quantified. |

|

| FIG. 2. The main components of a GC include a sample valve that mixes the sample with carrier gas, the actual separation column and the TCD. |

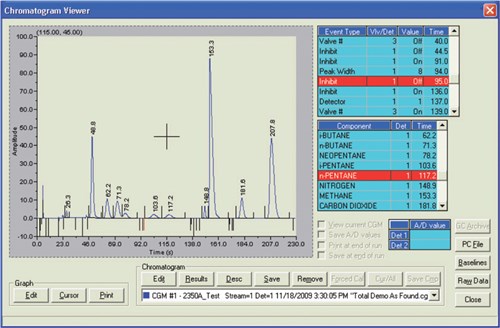

Signal processing by specialized software embedded in the GC determines which individual chemical components are present and in what proportions. These data are indicated by peaks on the graph (FIG. 3).

|

| FIG. 3. The presence of specific components is indicated on the graph, with amplitude showing quantity. Tabulations simplify the presentation. |

GC suppliers design their analyzers to fit the list of components that customers specify for their routine applications. Some cover a longer list of components than others, and this becomes a key specification, driving price and operational complexity.

For natural gas analysis, a basic GC can typically handle hydrocarbons through hexanes (FIG. 4). Anything above hexanes is simply combined into a single group, and the analysis assumes the C6+ peak consists of a fixed proportion of components outlined by GPA Midstream Standard 2261. For many applications, such as when a facility operating a gas turbine must ensure that the pipeline supply meets essential Wobbe Index requirements, this methodology is often sufficient.

|

| FIG. 4. Basic natural gas analysis can be covered by a C6+ analyzer.a |

However, more complex applications require deeper analysis extending to hydrocarbons through C9+ (FIG. 5). This is particularly critical when it is important to know which NGL might be included in the flow, along with the dewpoint where each will condense and form liquids in the pipeline.

|

| FIG. 5. Detailed natural gas analysis requires a C9+ analyzer.b |

For example, much of the gas coming from Canada and the northwestern U.S. has high concentrations of heavy hydrocarbons that are usually removed during processing and become a separate product stream. However, during winter-season periods when natural gas prices rise, the gas may be processed to a lesser degree to meet demand, leaving those heavier hydrocarbon components—including butane, propane, ethane and others—in the pipeline. Using a C9+ extended-analysis GC at these rich gas custody-transfer points enables a more accurate measurement than a standard C6+ analysis GC. This C9+ analysis separates and measures the hydrocarbon component groups of C6, C7, C8 and C9+.

For a GC, the difference between measuring C6+ and C9+ is a major step. A C9+ GC is effectively a C6+ GC with a second stage added to handle the heavier hydrocarbons. In a C6+ application using a GC with a backflush column arrangement, the analysis is performed using three valves, one column and one TCD in a single oven.

To perform C9+ application analysis, four valves, two columns and two TCDs are used in a single oven. The first TCD measures nitrogen, carbon dioxide and methane up through normal pentane. The second TCD measures heavier hydrocarbon component groups of C6 to C9+. The results from both detectors are combined in post-analysis calculations and reported together.

Hydrocarbon dewpoint. Hydrocarbon dewpoint is the temperature, at a defined pressure, at which the heavy hydrocarbons change from gas to liquid. Condensation is a problem since liquids in the gas stream can cause hydrate formation, increase compression costs, cause pressure regulators to freeze, damage equipment such as gas turbines, and react in undesirable ways when processed to create LNG.

Naturally, the hydrocarbon dewpoint changes with pressure, and sending a sample into a GC from a sampling point usually reduces its pressure, which may cause additional condensation. Sending a two-phase flow into a GC can result in significant measurement errors, so a sophisticated C9+ GC can usually calculate the hydrocarbon dewpoint at multiple pressures. This can indicate the cricondentherm, the highest hydrocarbon dewpoint at any pressure. Calculation of the hydrocarbon dewpoint at a pipeline’s flowing pressure and comparison of this measurement to the flowing temperature can provide an alert if conditions are approaching the potential for two-phase flow, providing the opportunity for operators to take mitigation efforts before problems arise.

Sulfur and other contaminants. So far, the discussion has primarily focused on measurements related to hydrocarbons. However, contaminants must also be taken into account. Sulfur has long been considered a contaminant with hydrocarbons, and the amount considered as tolerable has decreased as regulations have tightened. Sulfur content in natural gas varies according to source, from “sweet” (very low at ppm levels) to “sour” (high in percent levels).

Hydrogen sulfide (H2S) is usually removed as one of the earliest steps in processing, since not removing it can violate regulatory requirements (depending on the amount), reduce the value of the gas, and provide a source of corrosion to equipment downstream. Burning sour gas releases sulfur dioxide (SO2), which is a major pollutant.

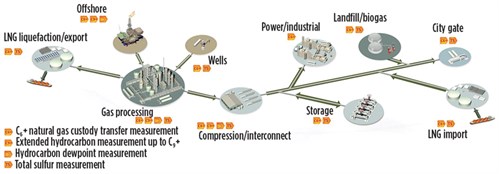

As a result, H2S content of natural gas (FIG. 6) may need to be measured at multiple points on the production and delivery chain:

|

| FIG. 6. In natural gas transmission applications, modern GCs can perform multiple measurements within one device, including hydrogen sulfide content. This reduces overall footprint, eliminates the need for multiple analyzers, and reduces CAPEX and OPEX costs. |

- Wellhead

- End-user plant inlet

- Amine sweetening process

- Sulfur recovery unit

- Sales gas pipeline compressor stations

- Odorant injection skids

- Underground storage injection and removal

- Routine custody transfer points.

Within a refinery, there are multiple points where accurate natural gas monitoring with sulfur measurements are necessary:

- NGL/LPG processing

- Fuel gas analysis

- Flare gas monitoring

- Feedstock analysis for use with petrochemicals, fertilizer, etc.

- Catalyst protection.

For a long time, measuring both total sulfur and H2S required two separate, dedicated analyzers. Total sulfur measurements were typically made using X-ray fluorescence to get a bulk reading with no breakdown of individual sulfur components. H2S analyzers were especially problematic due to the common use of mechanical systems requiring lead acetate tape or tunable diode laser technology. Now, however, these sulfur-related variables are simply on the list of values measured by a GC through the addition of a third measurement stage, using a different detector than for the hydrocarbons. Sulfur and its compounds can be accurately measured using a flame photometric detector (FPD) in conjunction with the conventional GC columns.

FPDs are usually included only in more elaborate analyzers, but the development of a micro-flame photometric detector (µFPD) makes it possible to include this technology on smaller, less-expensive, transmitter-style GCs. It is now possible to enclose the hardware for all three measurement stages in a single, airless oven, minimizing size and complexity.

Sulfur measurements are especially important as markets, such as the EU, are restricting sulfur content on imported LNG. Additionally, mercaptans, carbon dioxide (CO2), and carbon monoxide (CO) can be included in the analysis run. With all parameters included, a C9+ GC can measure approximately 13 components in the mix. All of these functionalities can be achieved with a single, standalone, field-mountable analyzer, thereby reducing CAPEX and OPEX, along with operator training and the overall plant footprint.

GC misconceptions. To some, the thought of analyzers of any kind suggests complex, fragile, bulky, expensive devices requiring elaborate housings, complex installations, many consumable supplies and sophisticated operator training. Fortunately, GC technology has evolved, making these types of analyzers far less costly and intimidating. Three areas have seen advances worthy of mention.

First, new µFPDs provide critical, sulfur-related measurement functions. These devices are far smaller and less expensive than traditional designs, allowing the full GC assembly to be much more compact and robust. They are also less expensive, reducing the cost of the entire installation.

Second, improved software provides more automated processing and a more intuitive user interface to ensure consistent performance while reducing the need for extensive user training.

Third, the ability to reduce the size and fragility of internal valves and sensors makes it possible to reduce the footprint of a GC and eliminate the need for specialized enclosures. Some designs available today are explosion-proof and ATEX/IECEX safety rated. This means these devices are field installable without an enclosure, even in Class 1, Division 1 areas, thereby eliminating the need for air-purged enclosures in any environment.

Easier and less expensive. The ability to capture the data necessary to build a complete picture of natural gas characteristics is far easier than ever before. Multiple, dedicated, single analyzers have been supplanted by GCs and older GC technologies have been updated, resulting in today’s simpler, smaller, less expensive and more versatile offerings. Elaborate enclosures and costly consumables are no longer needed. Gas producers, pipeline companies and end users are getting the measurements they need without the complications, expense and maintenance requirements of older technologies and solutions. GP

|

JASON PRATT is a Global Product Manager for Emerson’s Rosemount gas chromatographs. He has more than 13 yr of experience in gas chromatography design, research and development, and he has received numerous patents for GC inventions. Mr. Pratt holds a BS degree in mechanical engineering and an executive MBA degree, both from Texas A&M University.

|

ASAD TAHIR is the Director of Product Management for Emerson’s Rosemount gas chromatographs. He has several years of experience

in online and lab chromatography, and he is a member of the Analytical Division of the International Society of Automation. Mr. Tahir holds a BS degree in biomedical engineering from the University of Houston and an MBA degree from Texas A&M University.

Comments