Case study: Improve gas processing by controlling condensation

Improved condensation and capture of NGL and water in natural gas cuts costs, maximizes production value, and avoids costly maintenance. Measuring and controlling temperature are key to success.

Occidental Petroleum Corp. is an international oil and gas exploration and production company with operations in the U.S., the Middle East, Latin America and Africa. It is the leading producer in the Permian basin fields of West Texas.

Occidental has a mainline facility in Catarina, Texas that receives crude oil and natural gas from multiple well sites in the Eagle Ford fields. This site can handle 320 MMft3 of natural gas, 4,000 bpd of NGL and 70,000 bbl of oil. Natural gas arrives via a 16-in. pipeline containing a mix of natural gas, NGL and water. Incoming gas goes through a slug catcher, where any NGL in the pipeline are captured, and then through a separation and cleaning process to break out the three product streams. Water is treated, and NGL are sent to another Occidental facility in Texas, while the processed gas is sent out via pipeline.

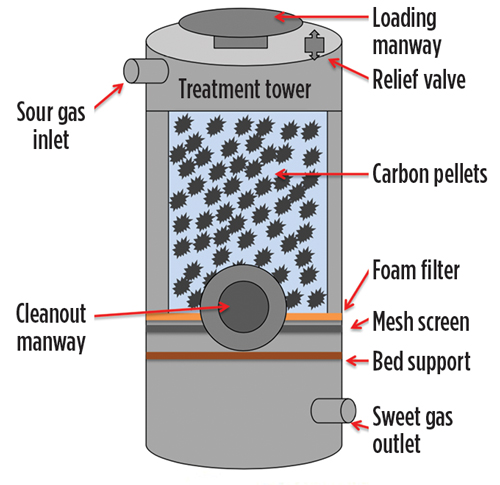

Many of the gas wells feeding Catarina also produce toxic and corrosive hydrogen sulfide (H2S) gas, making the natural gas “sour.” Before being sent to the pipeline, this sour gas needs to be “sweetened” by removing the H2S. The site has a series of six sulfur removal towers (Fig. 1), each filled with activated carbon pellets. The sour gas passes through the towers, and the carbon captures the H2S. When the carbon is fresh, removal is virtually complete, but over time the carbon begins to saturate. When the concentration at the outlet reaches a threshold point, the flow is directed to a different tower with fresher carbon, and the saturated carbon is replaced.

|

| Fig. 1. The treatment towers can operate for a number of days before needing a new charge of carbon particles, depending on the H2S content of the gas. The Catarina site has six identical towers. Diagram courtesy of Emerson. |

Normally, this is a straightforward process. The saturated tower is taken offline, emptied, and refilled. The pellets remain granular and can be removed through a clean-out hatch near the bottom during a single shift.

A simple task becomes difficult, expensive and time-consuming. One day, workers doing the carbon replacement made an unwelcome discovery. The normally granular carbon had turned into a porous solid mass, glued together due to liquids in the gas stream. A task that should have been simple turned into an ordeal stretching into weeks, requiring workers to blast the carbon out of the tower with high-pressure water jets.

Worse, it happened to more than one tower, racking up costs of $800,000 and drastically reducing processing capacity at the site as multiple towers went offline while waiting for clean out. A comprehensive analysis project determined the critical element was the temperature of the incoming gas. Just like humidity in the atmosphere, the gas temperature determines the maximum amount of NGL and water the stream can carry. If the temperature falls below the dewpoint, then liquids condense. Engineers analyzed the situation and determined that the dewpoint of the gas was usually around 78°F.

Maintaining this temperature is not a problem for much of the year, but during cooler months, a variance of as little as 4°F or 5°F could cause a problem. The gas coming into the sulfur removal towers needed to be warm enough to keep the NGL and water gaseous so they could pass through the tower without condensing. The stream would then move to the dehydrator (dehydration unit), where any remaining NGL and water would be condensed and separated. The ultimate question asked by the study was: Does a mechanism exist to monitor and control the gas temperature so that it stays above the dewpoint at the inlet of the treatment towers?

With additional examination, it became clear that the problem was even worse than realized. In addition to gumming up the treatment towers, the NGL that condensed between the slug catcher and the dehydration unit robbed the site of product—about 12,000 bbl/yr of NGL—rather than capturing it and selling it via the normal NGL product stream.

One suggestion involved adding heat tracing and insulation to the treatment towers. With a cost of $450,000, however, this was considered far too expensive.

Heating the gas stream. Gas arriving at the Catarina facility comes from a compressor station approximately 1 mi upstream. The station has the capability to heat the gas, at least enough to avoid problems in the treatment towers. Heating requires energy, so there is no incentive to overheat the product; plus, there is a temperature limit of 130°F for the compressors, so an alarm set at 100°F avoids a trip.

Engineers trying to implement this solution discovered there were few sensors installed to monitor temperature, and the amount of time necessary for the gas to travel from compressor to Catarina made a closed-loop solution appear impractical.

It became clear that solving the problem would require adding more temperature measurement points at strategic locations throughout the facility. This in itself presented its own set of problems. First, the automation system controlling the facility did not have open I/O slots to add more inputs from instruments. Second, welding thermowells into the existing piping would be a major undertaking:

- The facility would need to be shut down, and the affected lines purged with nitrogen

- All the welds would need to be X-ray inspected

- During the shutdown, production would have to be stopped at roughly 100 wells feeding the facility

- A shutdown would cost the facility about $1 MM/d.

Hot-tapping methods were proposed as an easier alternative, but dismissed as presenting too many safety issues.

The problem was solved using an externally mounted surface reading technology, which is able to perform its action without a process penetration of any kind (Fig. 2). Each unit combines a resistance temperature detector (RTD) sensor with a WirelessHART transmitter designed to mount on the outside of a pipe using a clamp. The sensor makes firm contact with the surface of the pipe so it can measure the heat being transferred through the pipe wall from the gas inside. Based on pipe dimensions and material, it is able to calculate the internal reading based on the amount of heat transferred through the pipe wall.

|

| Fig. 2. The temperature transmitters mount to the pipe using a clamp without the need for a penetration or welding. With a WirelessHART transmitter and internal power, no wiring of any kind is necessary for the installation. Photo courtesy of Emerson. |

The WirelessHART transmitter sends temperature data to a gateway, which interfaces with the facility’s automation system via a Modbus digital communications link. This avoids the need for additional cabling, and solves the I/O limitations.

Practical operation. Since many factors affect how much heat is transferred through the pipe wall, the signal processing software requires very specific information about the installation, which it combines with the RTD’s measured data. During configuration, the pipe material and wall thickness at the position where the sensor is mounted was entered to provide accurate heat transfer characteristics.

The pipe must be insulated for at least 6 in. on both sides of the sensor to minimize the effect of any ambient temperature difference and air movement, both of which can affect the amount of heat transferred through the pipe wall. The insulation helps, but the accuracy of the reading is not fully dependent on it because the transmitter has its own internal temperature sensor to measure the ambient temperature and do its own corrective calculations.

Once installed, configured and operating, the new temperature transmitters provided continuous, accurate and repeatable temperature readings of the gas inside the pipe, without any penetrations. The temperature instrument can be removed from the pipe and moved to take a reading in a different location.

New surface-reading transmitters were installed in four locations:

- 16-in. incoming natural gas line (Fig. 3)

- 24-in. inlet and outlet pipes for the slug catcher

- 16-in. treatment tower outlet pipe.

|

| Fig. 3. Pipe diameter is not a serious issue for the temperature transmitters because the technology works just as well on a 24-in. pipe as on a 1-in. pipe. (Insulation removed for photo.) Photo courtesy of Emerson. |

These transmitters send their data to the automation system using WirelessHART via a wireless gateway. After the individual transmitters are joined to the network, using the appropriate security steps, the network organizes itself so that the transmitters can communicate with one another and the gateway.

Given the low density of equipment at the Catarina site, communication is largely line-of-site, and keeping data flowing over the wireless network has not been a problem. Now that the gateway is installed and working, the WirelessHART network has capacity for many more wireless transmitters.

Takeaway. When all possibilities were examined, measuring temperature using the surface-mounted transmitters and a WirelessHART network proved to be the lowest-cost option.

This option avoided adding to the already-stretched capital expense budget. It was also the fastest option to implement, with no operating shutdowns required, so the site did not experience a loss of income. All the wells continued to produce with no interruption, with no special work permits required and no safety concerns created with hot taps.

Now that the network is in place, Occidental is examining even more opportunities to deploy additional wireless instrumentation to help control and optimize processes at Catarina and other locations. GP

Chris Diaz is a Senior Automation Engineer for Occidental Petroleum Corp., based in the Woodlands, Texas.

Comments