Predict centrifugal compressor performance in off-design condition

Centrifugal compressors are vital components within process plants. The capability to detect early indicators of malfunctions in these machines, and to identify and understand their causes and possible remedies in a timely way, helps minimize overall operational costs. This trend is known as predictive maintenance. For common centrifugal machines, predictive techniques are applied to the vibrational and structural dynamic aspects of machine rotor operation. On the operation floor, machine vibrational parameters are measured and compared to acceptable limits and used mainly for alarm triggering.

Predictive maintenance for compressors. Predictive strategies based on performance analysis are a tool for diagnosing and evaluating machine health status during operation. For centrifugal pumps, for instance, the use of machine modeling to compare measured performance and design performance is relatively easy and straightforward. For centrifugal compressors, however, the same process is more complex due to the dependency of compressor performance on the gas mix composition and the operational inlet conditions (i.e., pressure and temperature). An approach based on performance assessment for centrifugal compressors requires a more complex machine model.

Analyzing the operating performance of centrifugal compressors requires the ability to adjust the compressor performance map to actual inlet conditions. Expected performance is described in graphs of discharge pressure, discharge temperature, polytropic head, efficiency and absorbed power. However, inlet conditions in the field may be different from the specifications defined on machine data sheets.

One practice attempts to reduce the complexity of this disparity by considering the compressor head as invariant with respect to inlet gas conditions, and applying simplified machine formulas. This method works for very-low-pressure ranges and constant gas mixes, but it introduces errors with rising pressure and gas mix variability. In this situation, it is necessary to adjust the compressor design performance to operating performance and compare the results to measured values. This is basically the approach indicated in ASME’s Performance Test Code on Compressors and Exhausters 10 (PTC 10) standard.

A general method and calculation tool for the prediction of centrifugal compressor field performance in off-design condition is presented here. All numerical evaluations executed with Cmap software have been developed using thermodynamic theories and machine aeromechanical models, in accordance with ASME’s PTC 10.

Process description. An explanation of the calculation process used to evaluate compressor performance is needed for a baseline. For a centrifugal compressor, performance is strongly linked to inlet gas conditions. This consideration is valid for both design and off-design performance.

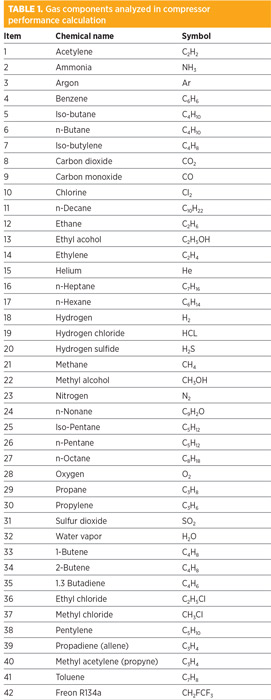

Data to be used as a starting point include the centrifugal compressor performance curve, the relevant gas mix composition and the thermodynamic conditions (pressure and temperature). After entering these data, the software calculates the expected compressor performance for inlet pressure, inlet temperature and gas mix composition for the design and reference scenarios. Calculation algorithms are able to predict both machine behavior and thermodynamic real gas properties in off-design conditions. Table 1 shows a typical list of gas components to be configured.

|

From a fluid dynamics point of view, it is necessary to achieve strict similarity of flow at each performance point. For this reason, the parameters of head coefficient, flow coefficient and Mach number must be conserved. The proposed method requires the following inputs:

- Reference/design compressor maps. In general, these maps (provided by the machine OEM) give a reliable indication of machine capability and are considered as a starting point. Expected performance maps are usually issued in the commercial/design stage, and test performance maps are issued at the end of the manufacturing process, after the compressor has been shop or field tested. The data from either map may be used as inputs for the method, although “tested” maps may be preferable.

- Reference input conditions. Reference/design maps are linked to specific inlet conditions, such as inlet pressure, inlet temperature and gas mix composition. This set of data is needed to understand off-design calculations.

- Off-design input conditions. These conditions at the compressor inlet (pressure, temperature and gas mix composition) indicate a new performance. Off-design conditions can be considered for alternative inlet parameters in the compressor design stage, or they may be the actual inlet conditions at some point during the compressor operation.

Starting from the inputs described above, the compressor performance in off-design inlet conditions is calculated. Performance referenced as “off-design condition” is design performance adjusted to off-design operational conditions. When reference is made to off-design performance in off-design operational conditions during operation, this performance is referred to as “actual” performance.

Calculation of off-design performance requires extraction of invariant information related to the compressor behavior. This information is then used to rebuild the performance under new conditions. These calculations are intimately connected with the thermodynamics of gas compression and real gas mixtures, which means that variations in gas mixture components, pressure or temperature can manifest with significant effects. The connections among these different modeling areas allow the calculation method to provide an accurate prediction of compressor performance.

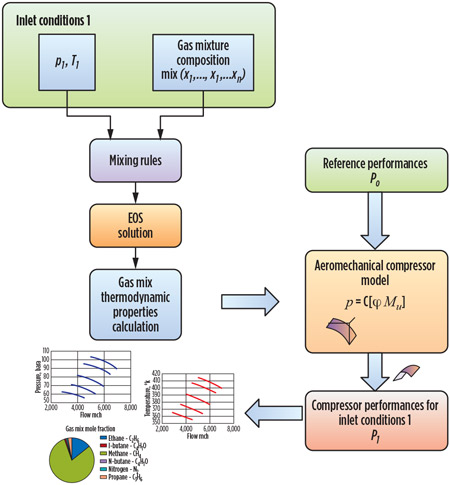

The method does not require information about the machine internals. In this sense, it should not be considered as a design tool, but more correctly as an analysis tool (Fig. 1).

|

|

Fig. 1. Diagram illustrating how Cmap works. |

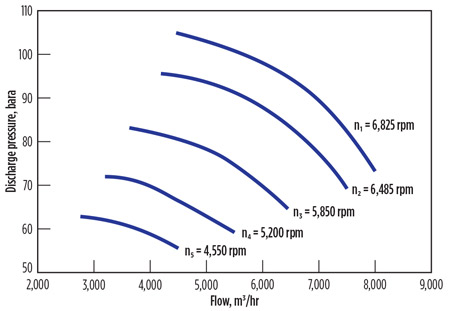

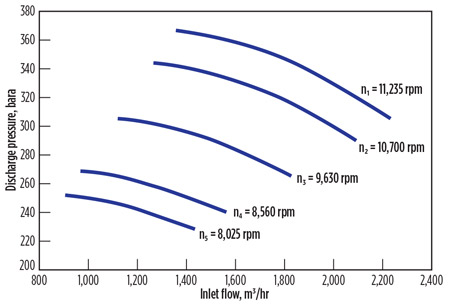

Case studies: Performance in off-design condition. The compressors under study were running in off-design inlet conditions. The analysis developed with Cmap allowed the machine operators to obtain compressor performance parameters in off-design conditions, and to compare these performance parameters to measured field values. Compressor performance maps for the design condition were available for both machines.

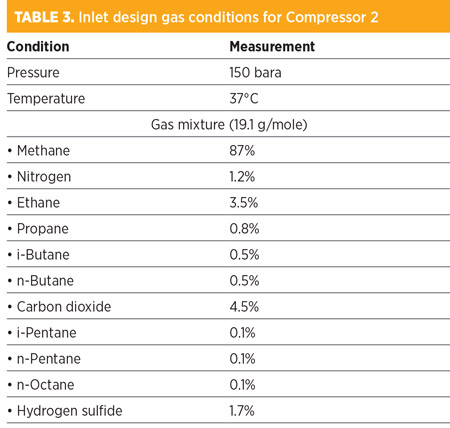

Fig. 2 and Fig. 3 show the design maps (discharge pressure vs. inlet flow) for Compressor 1 and Compressor 2. Table 2 shows the inlet design gas conditions for Compressor 1, and Table 3 shows the inlet design gas conditions for Compressor 2.

|

|

Fig. 2. Design map for Compressor 1 showing discharge pressure vs. inlet flow. |

|

|

Fig. 3. Design map for Compressor 2 showing discharge pressure vs. inlet flow. |

|

|

The expected performance curves in the off-design conditions were also calculated.

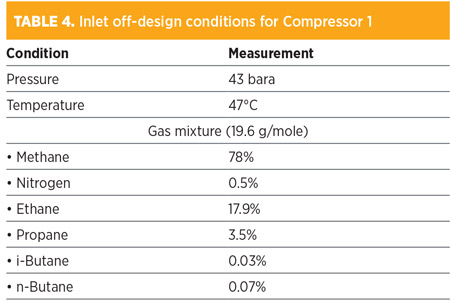

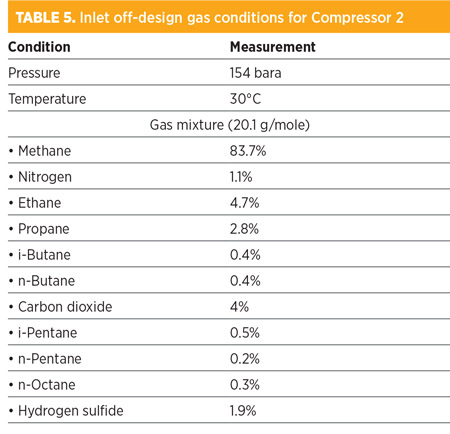

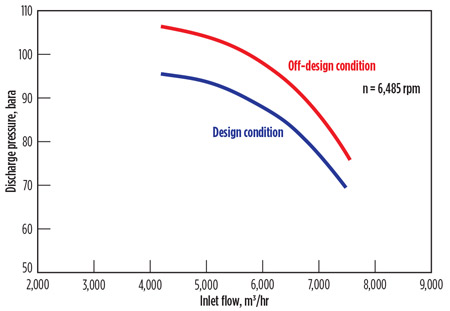

Table 4 shows the off-design inlet conditions for Compressor 1, and Table 5 shows the off-design inlet conditions for Compressor 2. Fig. 4 compares the performance curves (discharge pressure vs. inlet flow) in the design and off-design conditions.

|

|

|

|

Fig. 4. Comparison of discharge pressures between design and off-design conditions for Compressor 1. |

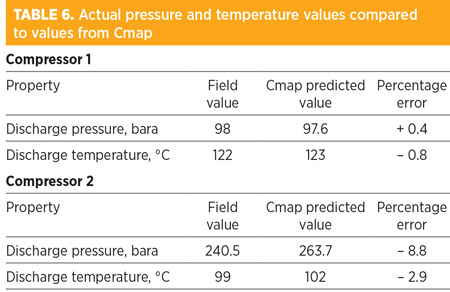

The Cmap software calculated, at the actual flow, the values of expected pressure, temperature, head and efficiency in the actual (off-design) conditions, and then compared these values to the measured ones. With reference to the field values, Table 6 compares the pressures and temperatures, as read from the transducers, to the values predicted by the Cmap software. The same comparison has been executed for head and polytropic efficiency. Note: In previous tables, the maximum error calculated for Compressor 1 is less than 1%, while the error calculated for Compressor 2 is approximately 9%.

|

The Cmap analysis indicates that the operating performance of Compressor 1 was aligned with design expectations. Compressor 2, however, was not performing in alignment with design expectations. This comparison gives an important quantitative indication of the machine health status.

The analysis also allowed machine operators to obtain an evaluation of the efficiency deviation—the difference between the actual compressor efficiency and the expected efficiency in the operating condition. Time trends for the calculation results provided a useful analytical basis for compressor maintenance decisions. The method has been profitably used to predict compressor performance and support machinery maintenance planning.

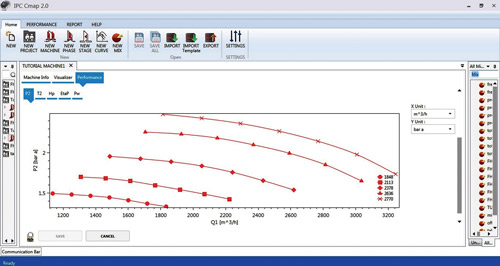

Cmap allows compressor performance predictions to be made (Fig. 6), using different equations of state (EOS) and different gas mixtures. For hydrocarbon gas mixtures, the Lee–Kesler method or the Peng–Robinson EOS can be used. For freon R134a, the modified Benedict–Webb–Rubin EOS is selected to determine the thermodynamic properties of the operating fluid.

|

|

Fig. 6. Screenshot of compressor performance prediction in Cmap 2.0. |

Recommendations. Experience with real machinery showed that compressor performance predictions obtained with Cmap software are in good alignment with OEM predictions and field measurements for machines in good condition. Experience also showed that, in most cases, the deviation of some parameter (e.g., efficiency) indicates the likelihood of an impending problem with the machine.

The proposed calculation method may be used in a fully automated way and could provide significant benefits, especially for machines that work in high-pressure and very-high-pressure ranges, and under process conditions with rapid time variances. The automated application of Cmap presents the possibility of continuous monitoring of machine performance and, therefore, offers automated surveillance and diagnostic capabilities. Protection of the compressor from surge can be automatically and continuously updated to correspond with actual inlet conditions, thereby overcoming the limitations of actual systems.

Methods described in this article offer a number of solutions for various capabilities:

- Predict the performance of a centrifugal compressor in off-design condition accurately, even at high pressures, when the ideal gas commonly used introduces considerable errors.

- Predict the modification of surge points in actual operating conditions, with different inlet pressure and temperatures and different gas mixtures, to implement advanced protection from surge.

- Obtain useful indications (diagnostics) on the health of the compressor, based on the ability to analyze the performance and efficiency of the machine in a simple and immediate way.

- Support decisions and planning for predictive maintenance activity. GP

|

Massimiliano Di Febo is the Operation Manager for IPC Industrial Plants Consultants. He holds an MS degree in mechanical engineering and is a registered Professional Engineer in the province of Bari, Italy. Mr. Di Febo has more than 15 yr of industry experience, working with specifications, applications, installations, diagnostics and maintenance for IPC and having conducted centrifugal pump testing at GE Nuovo Pignone.

|

Pasquale Paganini is Technical Manager for IPC Industrial Plants Consultants. He holds an MS degree in mechanical engineering and specializes in thermodynamics and energy systems. He is a registered Professional Engineer in the province of Bari, Italy. He has more than 15 yr of experience in the automotive industry (testing, instrumentation, manufacturing and quality), as well as experience working with specifications and applications for IPC.

Comments