Dynamic optimization of integrated electricity and steam network

Cost reduction and energy efficiency have been priorities for most industrial plants in recent years. A cost-effective way of achieving these efficiency improvements is the application of advanced process control (APC) technology. Although application of this technology has traditionally been focused on production units, the industry is now exploiting this technology on utilities, boilers, power generation and other ancillary systems. APC software consistently delivers more efficient process operation by providing a consistent and tenacious optimizer, or “cruise control,” for the control room operator.

The Santos Ltd.-operated Moomba gas plant (Fig. 1) in South Australia has been progressively applying APC across the highest-value sections of the process. These applications have produced compelling economic and operability benefits. The site has more than a decade of collaboration with an APC and optimization engineering consultancya on the application of linear APC technology to achieve its process efficiency and operability objectives.

|

|

FIG. 1. The Moomba gas plant in South Australia. |

Unlike traditional APC software applications, online optimization of utility systems requires real-time coordination of multiple process components like boilers, gas/steam turbines, letdown systems that can be very nonlinear and highly dynamic in nature, and optimization decisions that regularly include discrete variables. This case study describes the application of a new generation of online dynamic optimizer technologies to coordinate and optimize the nonlinear process aspects of utility systems.

Project objectives included:

- Minimize overall fuel gas use required to produce steam and electrical power

- Automate the optimization to reduce operator workload

- Minimize both high-pressure (HP) and low-pressure (LP) letdown and the LP steam header condensing by adjusting the load on the steam-driven alternators and fan condensers

- Balance the electrical system frequency using the gas-driven alternator load

- Balance the electrical generator power factors

- Absorb system load disturbances regularly experienced due to changes in ambient temperature, process driver load demand and electricity demand.

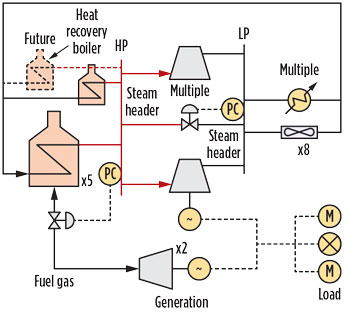

Process description. The Moomba steam and electrical system is a complex and highly integrated cogeneration system. HP steam is generated in gas-fired and waste heat boilers for several uses, including driving process pumps and generating electrical power using steam turbine alternators (STAs). Electricity can also be generated using gas-fired gas turbine alternators (GTAs).

The amount of power required to run the plant and ancillary systems is determined by the demand from the process equipment that is being used. As this system is an electrical island (it is not connected to the grid) and there is no storage of electrical power, the amount of power generated must exactly match demand. Total power produced is often around 8 MW, from up to two GTAs and up to three STAs of varying capacities.

Steam exhaust from the STAs and other HP steam users feed the LP steam header. LP steam is mainly used for heating in the process units before being recycled as boiler feedwater. The LP steam usage varies depending on the process demands. If LP steam is insufficient, then HP steam is desuperheated and let down to the LP header. Any excess LP steam is condensed and recycled as boiler feedwater. The LP steam condensers have remote-controlled fixed-speed fans to adjust the rate of condensation. Fig. 2 shows a simplified process flow diagram of the utilities system.

|

|

FIG. 2. Simplified flow diagram of the Moomba utilities system. |

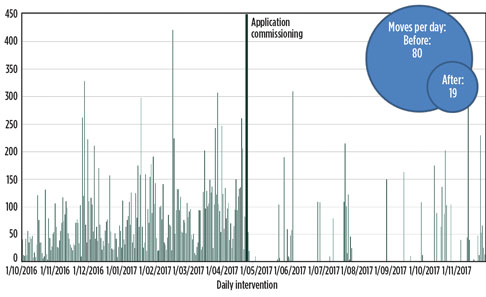

Operational challenge. Electrical voltage and frequency are controlled in real time by automated systems; however, a significant amount of operator interaction is necessary to keep these parameters balanced and at target. The split of power generation between the STAs and GTAs, power factor balancing, and the operation of the condensing fans were manual tasks that required operator focus and numerous operator-initiated adjustments every day.

The continual load disturbances on both the electrical system and the steam system experienced during the day and night left the operators with a relatively labor-intensive job to both maintain the required operating envelope and optimize plant operation. This was a key part of the panel operator’s task. With a focus on cost and energy minimization in the low oil price environment, this had led to sometimes several hundred moves on these generators in a day.

Technical challenges. Several challenging aspects of utility systems dictated a rethinking of the online optimization technology to be used. Specific characteristics of the problem that challenged the use of traditional APC technologies are outlined in the following subsections.

Strong non-linearities. When a fan is started, the capacity of the LP steam condensers changes significantly. As a result, determining which fans should be running is a difficult challenge for traditional APC technologies, as they are not well-suited to large changes in process gain, or to making an optimal and stable decision relating to equipment on/off states.

Equipment interface. The operator interface to the generator controls is via electronic “push buttons” that send timed pulses from the distributed control system (DCS). The interface to the fans is via run/stop requests. Traditional APC cannot interface to push buttons, and considerable effort is required to modify the generator controllers to construct an analog input.

Integer variables. Many of the important process and optimization handles in utility systems are integer variables, as opposed to more typical analog variables. Primary examples of these are the on/off (Boolean) condenser fan status and the GTA load, which has multiple discrete load levels. The selected optimizer technology has built-in capability to optimize discrete variables like equipment on/off statuses and integer load levels. Other major challenges associated with these variables are achieving solution stability and avoiding the risk of a limit cycle.

Speed of process response. The system responses of some parts of utility systems are in seconds, as opposed to traditional processes managed by APC with steady-state times of many minutes to hours. For example, the electrical system frequency and voltage have disturbances that require responses in seconds. The DCS regulatory control manages the second-by-second control requirements, while the new application optimizes this fast-responding system.

Lack of instrumentation. As with most industrial systems, not every stream flow is measured. The DCS manages this by controlling the steam pressures, which inherently closes the mass balance. While this works satisfactorily, it does not support traditional optimization technologies that are attempting to optimize the mass balance. The optimizer’s gray-box modeling approach enabled fast calculations of multiple unmeasured stream flows for use in its online, real-time optimizer.

Introduction of new technology. The aforementioned challenges dictated a rethink of the technology to be deployed. The site uses multiple MPC technologies, some of which were implemented in 2006. None of the existing technologies could be interfaced with the push buttons, and due to limitations in the control system, the push buttons could not be converted into a continuous variable without significant changes to those systems.

The solution in this case was to keep the fans as binary variables (only on or off) and modify the control system to control the load on the generators as integers with adaptation of the operating interface. The optimizer technologyb selected has the option to specify a manipulated variable (MV) as a continuous, integer or binary variable. Additionally, the gray-box modeling approach easily facilitates the nonlinear model gains that were fundamental to the problem.

Plant testing. Developing the optimizer model did not require extensive and intrusive plant testing. The models were generated from a Microsoft Excel spreadsheet, using engineering relationships such as mass balances and steam to power curves. Dynamic relationships for some of the variables were obtained from a brief plant test, but most of the relationships were taken from spreadsheets that the process engineers already used for monitoring the process.

Project benefits. The Dynamic Optimizer project generated significant benefits in energy savings, operational improvements and equipment reliability improvements, as outlined.

Energy savings:

- Generated savings paid for third-party engineering and software costs in less than 6 mos by reducing fuel gas consumption while maintaining balanced electrical generation.

- The optimizer is an enabler for fully capturing the benefits of other operational improvements. When any other action in the plant adjusts steam use, the optimizer immediately shifts the electrical load to the more efficient generators, with immediate fuel gas savings. This was highlighted when a plant change for steam efficiency was translated directly into fuel savings—without any additional workload on the utilities operator.

Operational improvements:

- The optimizer manages the process leading to extremely long periods of no operator interaction at all (up to a month between operator interactions). Most of the interaction now is during discrete process upsets that are outside the scope of the application. Fig. 3 shows that intervention was no longer required daily.

- Average operator moves on the generators were significantly reduced from more than 80 to less than 19 moves per day—a 77% decrease.

- The optimizer helps the operators meet the fuel minimization objectives and is highly accepted, with an uptime of approximately 95%.

- An estimate of the internal engineering time spent vs. the operator time saved by the application provides a time investment payback of approximately 9 mos.

- Equipment reliability improvements:

- Start/stop cycles were minimized on individual dump condenser fans by rotating the start sequence to maximize run life.

- The project also minimized steam hammer and potential damage through the addition of pressure controllers to prevent the formation of vacuum on dump condensers.

|

|

FIG. 3. Reduction in required operator interventions. |

Sustainable platform for future system efficiency improvements. The introduction of new technology can be challenging for a remote site where specialist engineering support is not locally available, and where the “fly-in, fly-out” nature of the workforce tests the ability of the site personnel to sustain new techniques. Sometimes, changes in context and/or discrete manual procedure events occur that can render a model-based solution ineffective, and this can erode the confidence of the operators to maintain use of the application.

In this instance, the system has run reliably with minimal support from the central engineering project team, and with sustained uptimes of > 95% in the 20-plus months that the system has been online to date. These results reflect the robustness of the optimizer platform, the fit-for-purpose nature of the application design and the level of operator training provided during its commissioning.

Furthermore, the application is seen to be a means of realizing the full benefits of a range of planned system hardware enhancements:

- Addition of a heat recovery steam generator (HRSG) unit

- Reconfiguring the steam dumping arrangement so that the initial excess LP steam is consumed in one of the process heaters, rather than condensed in the dump condensers.

Accordingly, the site can exploit the additional DCS operator bandwidth that is now available, knowing that evolution of the network design will not erode these achievements.

Takeaway. This joint optimization initiative demonstrates how online optimizer technologies can be used to automate challenging operations, thereby significantly reducing operator workload and increasing plant energy efficiency.

In this case, the optimization would not have been feasible without the introduction of nonlinear dynamic optimization technology to manage the highly nonlinear interactions and the ability to handle binary and integer variables. The result is improved operability and energy efficiency of the plant using only software to optimize the existing equipment, without any process interruption or mechanical modifications. GP

Notes

a Greenfern Dynamics, previously known as Apex Optimisation, is an APC engineering consultancy based in Australia.

b Generic Dynamic Optimisation Technology (GDOT™), owned by Aspen Technology Inc.

|

Stephen Gray is a Senior Consultant with Greenfern Dynamics in Australia. He has 20 yr of experience in the operation and optimization of process plants through roles in operating and technology companies in Australia, Asia, Europe and the US. Mr. Gray holds a BE degree in chemical engineering from the University of Adelaide and is a Chartered Member of IChemE.

|

George La Grange is a Principal Consultant with Greenfern Dynamics in Australia. He has more than 20 yr of experience in the design, development and maintenance of APC applications, collected through mineral processing, technology company and consulting roles in South Africa and Australia. Mr. La Grange holds a BE degree in chemical engineering from the University of Pretoria and is a chartered professional member of Engineers Australia.

|

Tristen Brew is the Advanced Process Control Lead at Santos Ltd. He has 15 yr of experience in the oil and gas industry and 7 yr of experience as a Process Control Engineer. He holds a double degree in chemical engineering and mathematics and computer science from the University of Adelaide in Australia

Comments