Steam purity assessment to prevent turbine malfunctions and performance loss

M. Macero and M. Sabban, Saudi Aramco, Dhahran, Saudi Arabia

An oil producer is carrying out ongoing projects to install steam turbine generators (STGs) in three aged gas plants. The projects were proposed as an energy recovery opportunity to better utilize excess steam from the cogeneration plants.

Although steam purity in the plants was not initially thought to be an issue, this idea was challenged in June 2017 when a steam assessment investigation reported deviations to National Electrical Manufacturers Association (NEMA) standards on steam purity for power generation steam turbines (NEMA 24). The STG vendors advised the operator that the units would suffer performance and reliability deterioration if they continued to operate at the present steam purity.

An assessment by external labs in August 2017 showed better values after operational adjustment, although deviations in sodium and online cationic conductivity were still present. A thorough assessment was recommended to confirm purity parameter stability, as progress on the STG projects resumed.

The second study concluded that the cationic conductivity was exceeding the NEMA 24 requirement of 0.3 micromho (μmhos)/cm. The present value ranged from 0.5 μmhos/cm–1 μmhos/cm in the three locations. The remainder of the NEMA 24 parameters were met.

Optimized recommendations include the installation of mixed-bed cationic exchangers downstream of the demineralizer units in the three plants, as well as the installation of new online analyzers to monitor silica and conductivity downstream of the demineralizers and the pH of the boiler feedwater. These steps are anticipated to secure and sustain the steam purity according to NEMA 24 standards, reduce raw water consumption and enhance the reliability and efficiency of long-term STG operations. These modifications are being implemented in the plants and are expected to be finished by mid-2019.

|

|

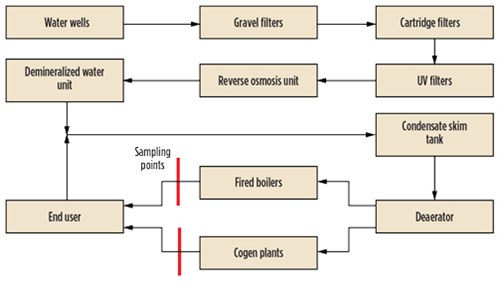

FIG. 1. Water treatment—steam generation cycle. |

Assessment methodology. The main steam source in the three plants comes from cogeneration cycles, and the balance is delivered from fired boilers. A condensed sketch of the water system treatment and steam cycle is shown in Fig. 1. Steam samples were collected from both parties as follows:

- Five-day composite samples were collected to ensure the accuracy and representation of steam results on each plant. Grab samples were also collected from each plant.

- Lab tests included the parameters listed in the NEMA 24 standard, excluding cationic conductivity, which can be measured only by online analyzers. Specific conductivity and pH were also measured.

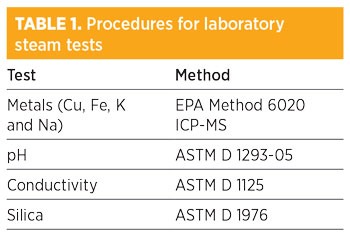

Cogen plants have available cationic conductivity online analyzers, so this parameter was also recorded during the assessment. The lab testing procedures for the analysis are listed in Table 1.

|

Findings. The remaining deviation in the steam is high cationic conductivity in the three plants; meanwhile, the rest of the values meet the specifications required in the standard (Table 2). From a previous assessment at Plant 1 by a third party, the main source for the cationic conductivity values comes from chlorides. The reported values ranged from 11 ppb–68 ppb, which directly contribute 0.132 μmhos/cm–0.816 μmhos/cm of cationic conductivity. NEMA 24 does not have specific requirements regarding chlorides content; only indirectly, through the cationic conductivity.

|

More recent standards, such as TS 61370 Steam Turbines Steam Purity, request values of 3 ppb for chlorides. The values for the rest of the parameters required in NEMA 24 were satisfactory in the three plants.

The water treatment systems in the three plants are identical, and the main reason for the differences in steam purity comes from the impurity level of the water source (groundwater wells), as can be seen from the difference in the conductivity values downstream of the reverse osmosis (RO) units in Table 3.

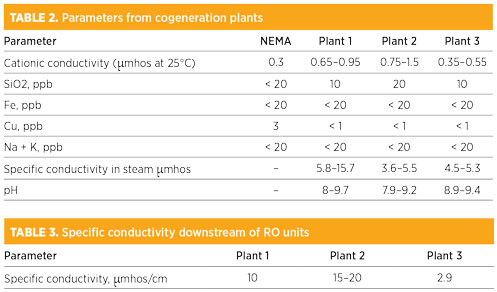

No iron or copper were found in the steam samples, which eliminates the need to condition the steam with a return condensate polisher. The demineralizer unit in Plant 1 was mothballed in 2009 due to safety issues, and in 2017, a steam turbine in a sales gas compressor became fouled and was overhauled (Fig. 2).

|

|

FIG. 2. Rotor and nozzle in steam turbine affected by silica/sodium fouling in Plant 1. |

Reinstatement of the demineralizer water units in Plant 1 is necessary, but not sufficient to ensure the required steam quality. Historical data trends from when the unit was in service show that the typical conductivity was 0.5 µmhos/cm, with sporadic spikes up to 1 µmhos/cm.

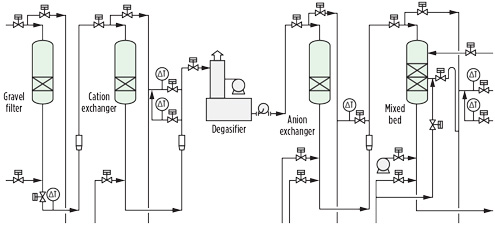

In Plant 2 and Plant 3, modifications are needed to satisfy standard requirements, as well. A typical technology to improve makeup water quality is the mixed-bed exchanger, which includes cation/anion resins together to remove residual minerals in the stream. This technology is in use in modern plants, where the steam purity is 0.2 µmhos/cm (Fig. 3).

|

|

FIG. 3. Demineralized water unit. Existing demineralizers have only cationic and anionic exchangers. |

The mixed beds should be installed downstream of the existing demineralizers (four trains in Plant 1, and three trains in Plant 2 and Plant 3). The design and configuration—i.e., centralized or per train—should be analyzed during the project engineering phase. The installation of these mixed beds will allow a 10%–15% reduction in groundwater consumption and the optimization of water resources utilization. The application of this technology will minimize blowdown from the boilers and enhance energy savings through the reduction of heat loss. Finally, fouling and corrosion in the turbine will be prevented, thereby maintaining long-term efficiency.

An additional technology update in the demineralizers of the three plants requires the installation of online analyzers to monitor specific conductivity, pH and silica. This instrumentation can be obtained for a relatively low initial cost and maintenance cost. The pure element monitoring requires frequent reagents makeup. Meanwhile, the cationic conductivity monitoring requires cationic resin columns, which must be replaced bimonthly.

Conclusion of plant modifications is expected by mid-2019. GP

|

Mario Macero has worked as a consulting engineer for compressors and steam turbines at Saudi Aramco since 2014. He has more than 25 yr of oil and gas experience. His knowledge includes rotating equipment engineering duties at three petrochemical complexes operated by Pequiven, the petrochemical branch of Venezuela’s PDVSA. These duties cover machinery troubleshooting, upgrades and rerating for rotating equipment used in NGL, petrochemicals, fertilizers and power plants. At present, Mr. Macero is involved in mechanical drive and power generation steam turbine projects for energy recovery. He holds an engineering degree from Universidad de Carabobo and a major rotating equipment specialization degree from Universidad Simon Bolivar, both in Venezuela.

|

Mahmoud Sabban has more than 20 yr of experience in the oil and gas business. He started his career as a plant engineer and has held various positions throughout his career in facilities planning, commissioning and startup teams, project engineering, technical support and central engineering. At present, Mr. Sabban is a Lead Rotating Equipment Consultant and the Gas Turbine Standards Committee Chairman at Saudi Aramco. He sits on the board of directors of Gas Turbine Users International and represents Saudi Aramco at the American Petroleum Institute (API) and at the States of the Cooperation Council for the Arab States of the Gulf (GCC) Standardization Organization (GSO). Mr. Sabban holds an MSc degree in thermal power from Cranfield University in the UK.

Comments