New in Gas Processing Technology

YESCO introduces Schneider Electric software solution

YESCO Co. Ltd., a South Korea-based natural gas supplier, has implemented a Schneider Electric Monitoring and Control software solution, part of Schneider Electric’s Industrial Software Platform. Benefits include improved operational efficiency, and greater access and visibility to operational data.

The Industrial Internet of Things (IIoT), combined with modern supervisory control and data acquisition (SCADA) systems, offers the potential to gain greater access and insights from a broader array of assets and devices for improved data-driven decision support. This IIoT application allows oil and gas companies to be more proactive with maintenance and safety management programs.

YESCO implemented Schneider Electric’s System Platform as a SCADA solution to gain better access to data that was often not readily available to improve performance. After a 5-mos deployment and 9 mos of utilization, the following benefits were achieved:

- Increased customer satisfaction, brought about through a streamlined and more holistic systems management solution. With this solution, asset management and equipment trends can be more proactively managed, helping reduce unplanned downtime and service disruptions.

- A heightened level of safety management through better visibility and understanding of when maintenance activities should be scheduled and performed.

- Reduced personnel time with more efficient predictive maintenance and data analysis, which frees resources to perform other, value-added tasks.

Global support extended for remote facility operations

One year after the launch of its first remote operations center in France, Air Liquide has inaugurated its Smart Innovative Operations (SIO) Center for the Southeast Asia-Pacific region, located in Kuala Lumpur, Malaysia.

The SIO Center enables the remote management of production for 18 Air Liquide large-industries production units spanning eight countries across the region. It also enables the optimization of energy consumption and the improvement of reliability at these sites.

The SIO Center integrates, optimizes and remotely controls the operations of Air Liquide’s production units, leveraging predictive analytics and digital technologies. These capabilities allow Air Liquide to better predict and accommodate changing customer needs across the region, especially for the supply of oxygen, nitrogen, argon and hydrogen.

The new SIO Center complements the facility the Group opened in Shanghai in September 2017, dedicated to production units in China.

Through big data combined with human intelligence, the workflow of each Air Liquide production unit linked to the SIO Center is adapted in real time to the needs of each customer. The SIO Center enables ongoing responsiveness to customer demand, improves production unit energy efficiency, and leverages predictive maintenance to ensure continuous facility run time.

In the connected plants, new digital technologies are being deployed to simplify maintenance and inspection management operations. For example, connected eyeglasses allow operators to interface with experts located elsewhere, as they are assisted in their daily tasks by virtual reality-based training.

LNG transfer with emergency release coupling

Alpha Process Controls has expanded its family of Emergency Release Collar (ERC) Couplings to support the transfer of LNG to floating storage and regasification units (FSRUs).

With the increased use of FSRUs as moored storage terminals, Alpha has developed a 10-in. version of its field-tested, mechanical emergency release coupling system, capable of managing the ship-to-ship transfer of 2,250 m3 of LNG per hour per line. This will enable, when operating across multiple lines, the ERC systems to support the optimum transfer flow for an FSRU of 10 m3/hr–12,000 m3/hr.

The technology incorporates an engineered solution to manage low-pressure drops, which ensures that the transfer can achieve high flowrates. Installed aboard the FSRU, Alpha Process Controls’ coupling will be part of the pipeline that connects to the LNG carrier.

It features a two-stage operation that enables the controlled shutdown of internal valves (ESD1) and the coupling separation (ESD2), and can be operated mechanically or through an operator-controlled separation. The ERC can be specified with a pre-ESD1 alarm, which detects ship separation, and is linked to the ESD1 system to shut down flow lines.

This safety feature complements the ERC’s innovative, inbuilt damping system to reduce the effects of pressure spikes, should the coupling be called upon to separate during full flow transfer in the case of a separation event, such as vessel drift.

Optimize gas turbine efficiency

Orbital Gas Systems North America’s GasPTi device is used in process control applications to optimize efficiency and minimize maintenance for gas-fired compressor turbines.

GasPTi combines two patented gas technologies—the GasPT analyzer and the VE Technology sample probe and system—to create a method to determine natural gas quality in a cost-efficient manner.

First deployed in 2015, the speed and accuracy of the GasPTi device allows customers to precisely control the air-to-fuel ratio injected into its turbines to decrease fuel consumption, reduce emissions and improve turbine efficiency and life expectancy.

Lower boiloff rate LNG containment system

Daewoo Shipbuilding & Marine Engineering has developed Solidus, a membrane-type cargo containment system. Solidus maximizes containment system safety with two metallic barriers and an insulation material developed in cooperation with BASF.

Solidus is said to have a daily LNG boiloff rate of 0.049%, which is 30% higher than the lowest level of 0.07%. This means that a 170-Mm3 LNG carrier can transport its cargoes more efficiently and can deliver more LNG each year.

According to Daewoo Shipbuilding & Marine Engineering, the total LNG cargo that can be saved by using the Solidus system is estimated to be worth approximately $11.25 MM during its 25-yr operation.

Axens completes study for gas supply to Curaçao

Axens will perform pre-FEED engineering work to supply natural gas from Venezuela to Refineria Isla Curaçao B.V. in Curacao. The project is part of the Refineria Isla modernization project. The overall objective is to provide positive impacts on both the environment and refinery economics. These benefits will be achieved through the conversion of fired equipment from heavy fuel oil to natural gas. SOX, NOX and particle emissions will be reduced to under stringent international standards.

The required gas treatment facilities comprise a molecular sieve dehydration unit, hydrocarbon dewpointing and gas compression. Treated gas will be transported through a 16-in. subsea pipeline, approximately 90 km in length. Pipeline construction and the upgrade of fired equipment inside the refinery are expected to be completed by 2021.

Global patents for LNG with no external refrigerant

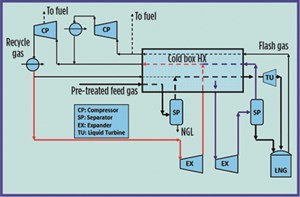

UK-based Gasconsult Ltd. was awarded a patent in China for its ZR-LNG liquefaction technology. This award complements its existing UK patent and pending applications in Australia, Canada, Europe, India, Japan, Korea, Malaysia, Mexico and the US.

ZR-LNG achieves liquefaction without external refrigerants, using feed natural gas in an optimized system of expanders. The elimination of external refrigerant infrastructure reduces cost, weight and footprint, making the process well-suited to FLNG.

The absence of nitrogen or mixed hydrocarbon refrigerants makes the process particularly suited for remote locations where refrigerant supply cost and logistics may be problematic.

ZR-LNG is said to achieve a power demand equal to or lower than single mixed-refrigerant processes, and approximately 25% lower than dual nitrogen-expander schemes.

Air Products acquires Shell coal gasification technology

Air Products has agreed to acquire Royal Dutch Shell’s coal gasification technology business, as well as Shell’s patent portfolio for liquids (residue) gasification. Air Products has extended its onsite supply model to use coal gasification to generate synthesis gas (syngas) for major projects.

Shell has been at the forefront of gasification innovation over the past 50 yr. Gasification technologies offer a way to convert various, lower-value feedstocks in a lower-emissions manner into syngas. Air Products can then provide this syngas to customers to make higher-value products.

Air Liquide emphasized that the acquisition supports its continued focus on providing a full scope of industrial gases, rather than a strategic shift into technology licensing.

In addition, Air Liquide and Shell have also formed a strategic alliance in liquids gasification to provide a range of solutions to the market, including engineering, procurement and construction activities and plant operations, as well as technology licensing.

Comments