Standardize compressor station design to reduce project costs and time line

S. Mokhatab, Consultant, Halifax, Nova Scotia, Canada; T. Cleveland, Cleveland Engineering Services Ltd., Calgary, Alberta, Canada; and S. P. dos Santos, At Work Rio Engineering and Consulting Ltd., Rio de Janeiro, Brazil

A principal component of any gas transmission system is the compressor station. A given gas transmission system may have anywhere from a few stations to more than 50, depending on feasibility studies. However, it is no longer economically feasible to provide an individual design for each gas compressor station.

Standardized design of compressor stations allows gas transmission companies to provide a design template for similar-sized compressor stations, resulting in reduced project cycle times and costs. More detail on this subject is provided here.

Introduction. Compressor stations are installed along gas transmission pipelines to boost the gas pressure in the pipeline to maintain the required delivery pressure and flow. Compressor stations comprise one or more compressor units that are designed with enough hp and throughput capacity to meet contractual requirements levied on the system. Each station will include a compressor and driver together with valves, control systems, exhaust ducts and noise attenuation systems.

Most compressors are powered by natural gas taken directly from the pipeline, but electric-powered compressors are becoming more common. A typical single-stage compressor station design (Fig. 1) may consist of an inlet scrubber to collect entrained liquids (i.e., water, corrosion inhibitors and/or hydrocarbon liquids that may have formed in the gas transmission pipeline), followed by a coalescing filter to remove fine solids (i.e., pipe scale) and hydrocarbon mist from the gas that could otherwise contribute to compressor failure. A coalescing filter also cleans the gas in each fuel supply to the turbines and gas engines.

|

| Fig. 1. Schematic process diagram of single-stage gas compressor station. |

From the scrubber, the gas is taken to the compressor unit(s), where it is compressed. At the compressor station discharge (or between compressor units, in the case of series arrangement) the gas is cooled, typically with an air cooler, and then passed through a scrubber, allowing drainage of any formed liquid. If a reciprocating compressor is used in the compressor station, then a coalescing filter should be used downstream of the outlet scrubber to remove lube oil mist prior to the gas being introduced back into the pipeline.1

Benefits of standardized compressor stations. Applying a standardized gas compressor station design in the construction of new gas transmission pipelines will reduce the project development time line and costs (CAPEX and OPEX). Reusable engineering allows the basic design phase to be omitted. With slight adjustments to a typical design, detailed design specifications for each individual station can be obtained.

This method also affects the procurement process in a number of ways. For example, the main equipment can be ordered prior to the completion of engineering work, since the configuration of the station has been specified in the typical layout presented for the target zone. Equipment is specified early in the standard package. Applying a type approval approach and frame agreement for procurement will help optimize planning. It will also ensure that stocks are adequate, but not excessive, for the project’s needs, thereby saving time and resources. Another benefit is the saving of time and manufacturing costs by using identical equipment in all stations in the same zone. Vendors will manufacture similar vessels and engines more quickly than the tailor-made design. Costs associated with tailor-made design manufacturing are also saved when using this method.

Moreover, a remarkable decline will be seen in the time spent to construct the station. Experience gained from construction of the previous compressor stations, accompanied by standard design and specified procedures, make this phase faster and more efficient. For instance, bottlenecks can be identified in the construction of the first station and properly dealt with and handled in subsequent stations. Note: Prefabricated compressor stations can also minimize work at the site and significantly reduce onsite construction time.

As in the construction phase, these merits benefit the commissioning phase of the project. The same procedure can be applied to both cold and hot commissioning of the equipment and stations within one zone, thereby making the work easier for commissioning. The cost of commissioning service can be reduced by utilizing local personnel who worked in the commissioning phase of the former stations in the same zone.

Similarly, benefits can be obtained in the operation of the station. Operators are an important part of every compressor station, and they play a critical role in the effectiveness and efficiency of any station. Given the fact that stations in the same zone are significantly alike, once operators and technicians are trained for a particular zone, they are then able to work effectively and efficiently in all stations in the same zone. Therefore, significant savings in time and budget for staff training will be realized. As a result, more flexibility will be seen in human resource management.

Another positive point in the lifecycle of compressor stations relates to maintenance of the station. Maintenance costs will be reduced, and procedures will be better understood, because the stations are similar. A maintenance team can work on any station within the boundary of a region without difficulty, as all aspects of stations are vividly known. New configurations and unknown problems need not be anticipated, since maintenance and troubleshooting will be similar for all stations.

In addition, for each zone, equipment spare parts can be purchased in bulk, since similar (or, in some cases, identical) equipment are in use in the same zone and can be used interchangeably in all stations within that particular zone. This leads to greater cost reduction. As a result, downtime will be shortened and the substitution of parts will be significantly easier.

In light of these considerations, standardizing gas compressor stations is becoming the new approach in the gas transmission industry, adding value (Fig. 2).

|

|

Fig. 2. Added values of standardizing gas compressor station.2 |

Type approved equipment. Type approval management on procuring equipment and accessories presents significant advantages, along with standardizing compressor stations:

- Speeds up the procurement process

- Reduces or eliminates inspections from purchasers

- Reduces repetitive engineering review and survey.

Flexible approach. Type approval is already a common approach adopted by such classification societies as the American Bureau of Shipping, Bureau Veritas, Lloyd’s Register and Det Norske Veritas. Once equipment—such as pressure vessels, pipes, valves, accessories or other materials—have received a seal of type approval, the process is completed and the purchaser does not need to expend time and resources to repeat the process.

Frame agreement. A frame agreement is a medium- to long-term collaboration between the vendor and the customer that sets prices and conditions for the supply of equipment to be maintained throughout the term of the agreement. This provision procurement process for critical equipment, such as gas turbines, gas motors and compressors, can facilitate a single communication from the customer to the vendor. Prices, technical specifications and general conditions have already been defined in the agreement, saving time and resources.

Standardized compressor station elements. Whether the standardized compressor station is a single unit or multiple units, it will comprise a number of elements or modules that conform to standard designs. The sizing of the modules will, of course, vary with the size and performance requirements of the compressors and the specific hydraulic design conditions of the system. These modules, representing standard designs, are summarized in the following sections.

Mainline block valves. Mainline block valves are attached to the pipeline with tee fittings, separated by a check valve on the pipeline.

Filtration and liquid separation. The filtration module will have screens for solids trapping and a cyclonic separator to remove liquids, which will be collected in a tank below the filter unit.

Suction valves. The suction valve will be located upstream of the compressor station.

Skid-mounted suction and discharge piping heads. Skid-mounted suction and discharge piping heads can be fabricated, inspected, hydraulically tested, transported and site-assembled. This approach expedites the construction schedule and minimizes the number of workers at the site. It will also simplify the installation demobilization and increase salvage cost. For short-term installations, it will allow reuse of the piping on a standardized design.

Skid-mounted fuel gas utilities. It is already common to include skid-mounted fuel gas utilities, which help reduce costs and shorten construction schedules.

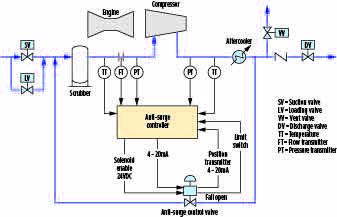

Compressor and drivers. The compressor and driver will be an integrated unit with a lubrication system, instrumentation and a data collection system, and will also include a recycle line and valve to maintain flow and prevent compressor surge for off-design operating conditions (Fig. 3).

|

|

Fig. 3. Compressor station anti-surge and recycle system.3 |

Valves. The discharge valve is placed at the exit of the compressor.

Equipment housing. The data reception, control equipment and power supply are structured as a separate unit, including batteries and a standby generator. Where required, the compressor and driver should be housed for weather protection and to accommodate the inlet filtration, exhaust stack and silencing system, and will be equipped with a ventilation system, hydrocarbon detection, fire detection and air dampening. In some locations where weather conditions are not critical, noise-producing equipment may be installed in containers, and housing may not be used. This will provide significant savings (Fig. 4).4

|

|

Fig. 4. Weather-exposed compressor station in Argentina.4 |

The provision of a building will also satisfy local environmental and noise regulations. Many considerations must be taken into account. One of the solutions adopted by a large gas company used a “box-within-a-box” construction. This setup utilized metal panels lined with sound-absorbent material, with the inner box separated from the outer box by an air gap of 1 m.

Control station. A control station designed to fit in a container, standardized, pre-assembled and pre-tested at the manufacturer’s facilities will reduce assembling and commissioning cost and time. It will also provide flexibility, should any need to replace the compressor station arise.

Site considerations. The layout of the modules described will be dictated to some extent by the site. Each section of the pipe between valves will be provided with a vent line, the exit of which will be placed at a safe distance from operating elements.

Takeaway. The layout of a compressor station is partially dependent on the site, the pipeline location, the limitations of other local properties, permissible noise levels and access. However, much of the work of engineering, design and procurement will be reusable. Ground conditions, soil stability and gradients of the specific site must be taken into account.

Nevertheless, standardization of the compressor station will have substantial benefits in the reduction of engineering design work and new drawings. Items such as the pipe anchors and supports, which are required to meet the limits of forces and moments on the compressor, will already be determined. This work represents a significant element in engineering design, which need not be duplicated in the standard design.

Overall, the standardization of gas compressor station design can significantly reduce cost and time for design and construction. Commissioning will be part of a standard procedure and familiar to operating staff. The overall time onsite will, therefore, be reduced, with resulting cost savings.

Standardized compressor station design can also offer significant benefits to operations personnel who become familiar with the equipment. Shifting of personnel from station to station will be expedited. GP

References

1 Mokhatab, S., W. A. Poe and J. Y. Mak, Handbook of Natural Gas Transmission and Processing, 3rd Ed., Gulf Professional Publishing, Burlington, Massachusetts, 2015.

2 Blume, A., “Standardization aids gas compression,” Hydrocarbon Processing, January 2014.

3 Kurz, R., R. C. White and S. Mokhatab, “Surge prevention in centrifugal compressor systems,” Pipeline & Gas Journal, 2013.

4 Santos, S. P., “Gas pipeline design under market risk scenario,” Rio Pipeline Conference and Exposition 2011, Rio de Janeiro, Brazil, September 20–22, 2011.

|

Saeid Mokhatab is an internationally recognized gas engineering consultant who has been actively involved in several large-scale gas field development projects, concentrating on the design, precommissioning and startup of processing plants and downstream transmission pipelines. He has authored or coauthored nearly 250 technical publications, and has received a number of international awards in recognition of his outstanding work in the natural gas industry.

|

Tony Cleveland is President of Cleveland Engineering Services Ltd. in Canada. He is involved in a number of energy-related projects, including improvements in energy utilization and efficiency. His early industry experience includes Bristol aero engines (later Rolls Royce), and Solar in the US. He then joined British Gas (BG) as Manager of its Machinery Department and was involved in the planning, design and selection of equipment for the BG natural gas transmission system. In 1975, he moved to Canada and worked on the Northern pipeline development with several major organizations.

|

Sidney Pereira dos Santos has worked as Executive Director of At Work Rio Solutions Ltd. in Brazil since 2012. Prior to 2012, he worked for Petrobras for more than 25 years as a senior consultant and gas pipeline design engineer. He has been actively involved in several international pipeline EPC projects, such as the design of the Bolivia-Brazil Gas Pipeline (GASBOL) and the expansion project of the gas pipeline network in Brazil. He was a key participant in many prospective projects, such as the Venezuela-Brazil Gas Pipeline and the Southern Cone Integration Gas Pipeline. He also provided consulting assistance to KazTransGas and Intergas Central Asia for the Kazakhstan section of the Trans-Asia Gas Pipeline.

Comments