New in gas processing technology

B. Andrew, Technical Editor

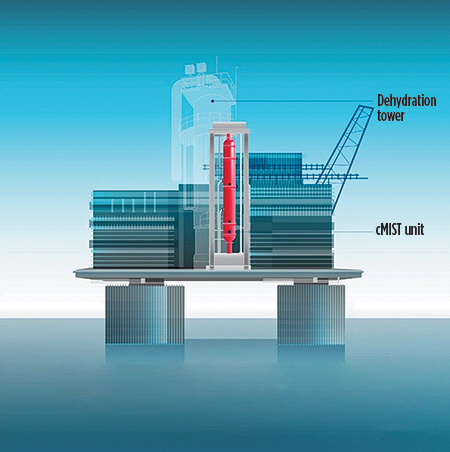

New gas dehydration technology

|

ExxonMobil’s new cMIST technology dehydrates natural gas using a patented absorption system inside pipes, and replaces the need for conventional dehydration tower technology. This “in-line” technology is designed for deployment at both land-based and offshore natural gas production operations. The new technology, developed and field-tested by ExxonMobil, is claimed to more efficiently remove water vapor during the production of natural gas. Removing water vapor through the use of dehydration technology reduces corrosion and equipment interference for the transport of natural gas through supply infrastructure and, ultimately, to consumers. cMIST reduces the size, weight and cost of dehydration, decreasing surface footprint by 70% and reducing the overall dehydration system’s weight by half, which has added benefits for offshore applications. ExxonMobil’s cMIST technology relies on a proprietary droplet generator to break up conventional solvent into tiny droplets that become dispersed in the gas flow, thereby increasing the surface area for the absorption of water from the gas. Then, an inline separator coalesces the water-rich glycol droplets and moves them to the outside wall of the pipe for effective separation from the dehydrated natural gas. The water-rich glycol is regenerated using a conventional system and is sent back to the droplet generator to be used again. The droplet generator uses the energy from the flowing gas to create droplets of the right size. ExxonMobil has licensed its cMIST technology to the Chemtech division of Sulzer.

energyfactor.exxonmobil.com/news/cmist/

In-line pipeline inspection

|

Direct assessment techniques are used to confirm measurements from in-line inspection (ILI) tools for pipelines. These tools are not always accurate and sometimes require recalibration. Service companies spend a considerable amount of time trying to correlate data between ILI tools and pit gauges (or any other direct assessment tool) to qualify the tool performance. To properly assess the performance of the ILI tool, pipeline operators must carry out year-on-year statistically significant population analyses with a device that offers better accuracy than magnetic-flux leakage (MFL) technology. Pipecheck’s corrosion software module from Creaform can be used to evaluate a pipeline’s fitness for service by providing fast, reliable data processing and instant onsite results. Pipecheck’s virtual pit gauge demonstrates increased accuracy and repeatability compared to traditional measurement methods, such as manual pit gauges, ultrasonic probes and single-line lasers.Creaform implemented a visual interface to perform in-line inspection correlation with the data acquired by its HandySCAN 3D scanner. The Pipecheck software solution offers the possibility to associate the corrosion and dent features scanned with the HandySCAN 3D with those identified by the ILI tool. Associations are automatically created when features overlap, and custom associations can also be computed. The software outputs an Excel report with visual graphics and tables detailing these associations.Additionally, the software identifies clearly unmatched features. The user interface is completely optimized to compare depth, length, width and even burst pressure.

www.creaform3d.com/en/ndt-solutions

Optimized smart flow instruments

|

Endress+Hauser recently released Proline 300/500, a family of industry-optimized “smart” Coriolis mass and electromagnetic flow instruments that simplify installation and speed commissioning, and that streamline operation and maintenance activities. The Promass Coriolis mass flowmeters are available in 11 models with up to a 14-in. diameter, to measure flows up to 100 Mtpd. Promag flowmeters are available in three models, in sizes up to 78 in. for flows up to 634 MMgpd. Both have models suitable for high temperatures, corrosive fluids, and hygienic and sterile process use. Proline instruments connect to control systems via 4-20-mA HART, WirelessHART, PROFIBUS PA/DP, FOUNDATION Fieldbus, Modbus, Ethernet/IP or PROFINET. They provide access via device display, web server, wireless LAN, handheld devices, asset management or process automation solutions, and Fieldbus. Each provides fast commissioning, in-situ device verification during operation, continuous self-diagnostics and automatic onboard data storage. Both families have robust transmitter housings available in aluminum or stainless steel. All Proline instruments have custody transfer approvals and meet the requirements of cCSAus, ATEX, NEPSI, INMETRO, EAC, IEC/EN 61326, NAMUR NE21, and EU and ACMA directives. They are approved for use in SIL 2 and SIL 3 applications. Each Proline instrument has a HistoROM function to protect data storage automatically. This function includes an event logbook and data logger that can be accessed locally or remotely, as well as storage for calibration and verification information. This onboard data storage makes it easy to replace and commission a new flow sensor. The built-in web server provides universal browser-based access to device, diagnostics and process information from any device with an internet or Wi-Fi connection.

www.us.endress.com/proline-300-500

Agreement for bioLNG, small-scale LNG

Gasconsult announced in September 2016 a patent application for a variant (ICR—Integrated CO2 Removal) of its proprietary ZR-LNG liquefaction technology. The ICR variant eliminates the need for a CO2 removal unit as part of the liquefaction feed gas pretreatment train. ICR is effective for feed gases containing up to 5% CO2. Gasconsult has formed an agreement with Osomo Projects BV to jointly pursue small-scale and biogas liquefaction projects with capacities of up to 60 metric Mtpy. Osomo has piloted a CO2- and water-removal system using membranes and a proprietary three-phase separator, in which solid CO2 and other solid contaminants (e.g., aromatics) are removed from the system after liquefaction. This technology is complementary to Gasconsult’s ICR configuration. Gasconsult and Osomo believe that a combination of their respective technologies (termed ZR-iLNG) provides a competitive and differentiated configuration relative to conventional small-scale liquefaction schemes. ZR-iLNG requires no refrigerant usage or refrigerant blending/storage facilities. It also eliminates amine systems, dehydration systems, chemicals, waste streams and heat sources. Gasconsult and Osomo plan to jointly pursue several biogas liquefaction projects in the Netherlands with the following objectives:

- First commercial demonstration of ZR-LNG or one of its variants

- Elimination of the amine unit and demonstration of CO2 removal post liquefaction, based on the combined Osomo and Gasconsult technologies

- Production of up to 10 metric Mtpy of profitable bio-LNG capacity for blending use with imported bulk LNG to meet Renewable Energy Directive objectives established by the European Parliament and the European Council.

Osomo and Gasconsult are now seeking partners to support the development of the first of these projects.

Comments