Centralized dehydration requires aggressive pipeline corrosion control

D. Wint, Audubon Field Solutions, Tulsa, Oklahoma

Dehydration plays an important role in proactively maintaining the integrity of oil, gas and multiphase pipelines. In addition to protecting the pipeline from internal corrosion caused by hydrogen sulfide, which is a byproduct of the metabolic processes of sulfate-reducing bacteria (SRB), removing water from the product stream is essential to preventing the formation of hydrates. It also helps ensure the safe, efficient and cost-effective operation of pipelines throughout their design life.

In traditional operations, dehydration takes place at the wellhead before raw gas enters the gathering line. Recently, however, an increasing number of operators have elected to perform dehydration at a central location away from the wellhead, in an effort to minimize OPEX, reduce labor requirements and streamline maintenance.

While these measures have helped companies achieve immediate cost savings, they expose the midstream pipeline infrastructure between the wellhead and the dehydration facility to harsh conditions. Ultimately, this requires operators to implement more aggressive corrosion control measures (Fig. 1), such as continuous chemical injection, slugging and more frequent pigging, to maintain the integrity of their lines.

|

|

Fig. 1. Typical setup of an internal corrosion monitoring system. |

Pros and cons of centralized dehydration. Maintenance represents a large portion of the cost of operating midstream infrastructure. Treating raw gas at a centralized location lowers costs by reducing the need for field personnel to continuously travel to multiple production sites to perform routine operations and maintenance (O&M) activities. However, this approach does not come without tradeoffs.

As mentioned previously, the primary concern with dehydrating gas at a central location away from the wellhead is internal corrosion. While the specific degree of corrosion is dependent on a number of factors, such as gas composition and flow velocity, failing to employ adequate corrosion control measures will increase the likelihood of failure and shorten the pipeline’s operating life.

This scenario was seen in the Eagle Ford Shale formation, where a field solutions provider worked with an operator employing centralized dehydration. The lifespan of the operator’s gathering system was reduced from 20 yr (design life) to 5 yr. The problem was even more severe for another operator in South Texas. The operator was experiencing internal corrosion issues only 2 yr after its gathering system commenced operations.

Another issue associated with dehydrating gas away from the wellhead is fluid accumulation. In any pipeline, liquids have a tendency to flow toward low elevation points, where they accumulate and form internal bore restrictions. When this formation occurs, the differential pressure in the line increases, and pumps must work harder to move product through the line. This results in higher energy expenses, more mechanical strain on compressors and reduced service life of equipment. Liquid loading is particularly problematic in the Marcellus and Utica shale plays, where steep terrain and significant elevation changes make it difficult to prevent liquids from collecting in low-lying areas, such as water crossings.

Determining the exact amount of liquid in a gas stream is dependent on a number of factors, including the stage of the producing well’s life and the specific area of the formation from which the gas originates. For these reasons, differential pressure is difficult to predict and can ultimately lead to variable throughput and flooding of gas processing equipment downstream. Both conditions result in decreased production and an increased need for maintenance, which, in many instances, can offset any front-end cost savings achieved by dehydrating gas at a centralized location.

Overcoming dehydration challenges. The inherent risks associated with the centralized dehydration of gas can be mitigated through a number of different methodologies, each of which presents unique advantages and disadvantages. Some of these methodologies are detailed in the following sections.

Continuous chemical injection. The widely accepted limit for water concentration in natural gas pipelines is 7 lb/Mscf. Concentrations above this amount will increase the chance of gas hydrate formation within the pipe when pressure in the line is reduced or when the temperature is near freezing. The most common method of prevention is to reduce the dewpoint of the gas by injecting methanol into the stream, thereby lowering its freezing point.

Since the amount of methanol required to effectively prevent hydrate formation is dependent on a number of variables, including gas temperature, pressure, water content and flow velocity, determining the proper dosage rate is often a difficult task. In many instances, operators will overestimate the volume of methanol required, with the mindset that too much is better than not enough. This concept also applies to the injection of biocides and corrosion inhibitors, which, like methanol, are atomized into the product stream in the hope that they will fall out at low elevation points, thereby mitigating the corrosion risk posed by accumulated water.

Aside from being inherently inefficient, continuous chemical injection typically represents a substantial operational expense. It also requires continuous monitoring of the product stream and its characteristics, as well as a detailed recording of injection events—both of which lead to greater operational complexity and higher costs.

Slugging. Slugging is similar to continuous injection in that a multitude of variables make it difficult to determine the exact amount of chemicals needed to treat water in the line. Moreover, operators often make the assumption that after being pumped into the pipeline, corrosion inhibitors will fall out at the same points where water has accumulated. Even in these cases, slugging can be ineffective because it often fails to treat top-of-the-line corrosion.

Automated pigging. In recent years, the use of automated pigging systems for the removal of liquids from gas pipelines, as well as for batching, has increased considerably. Unlike the continuous injection of chemicals, which poses challenges with regard to determining dosage rate, identifying the amount of chemical needed to batch is based on the circumferential area of the pipe, which is very easy to calculate. This effectively minimizes waste, reduces operational costs and provides a more efficient means of preventing internal corrosion.

Additional benefits of automated pigging. In addition to the advantages it offers with regard to corrosion control and integrity management, automated pigging provides a number of other value-adding benefits to a pipeline operation.

First and foremost, automated launchers allow for multiple pigs to be loaded simultaneously, thereby minimizing time and labor requirements that often plague manual pigging operations. This also eliminates the need to reduce pressure and vent pipeline contents every time a pig is launched, whether for batching or for liquid recovery. This greatly reduces the need to open and close valves and closure doors, and minimizes crew field time. Automated systems can also be remotely operated, which means that operators can perform launches from an offsite location, making an operation less prone to missed launches due to human error, environmental factors and other unforeseen issues that can occur in the field.

Aside from the benefits that arise from being able to more frequently pig lines between the wellhead and the dehydrating facility, automated pigging systems offer advantages with regard to worker safety. This is largely due to the fact that the field crew’s exposure to pressurized lines is minimized. In manual operations, it is often necessary for personnel to take measures to protect themselves against exposure to H2S gas that may be present in the raw stream. Automated systems ultimately reduce the need for crews to enter hazardous work environments, which is the most important step in decreasing the probability of an incident.

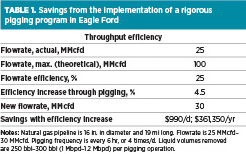

In the previously discussed case of the operator experiencing severe corrosion in the Eagle Ford shale formation, the field solutions provider installed an automated launcher that enabled pigging to be performed once each day. This operation allowed for the removal of free water from the pipeline, thereby decreasing the use of corrosion inhibitors, improving dispersion and preventing the downstream slug catcher from overflowing with liquids (Table 1).

|

Return on investment. In many cases, the savings incurred from reducing operational costs, preventing corrosion and being able to more efficiently conduct maintenance will offset the cost of installing an automated pigging system. How quickly capital costs are recouped will largely depend on how often a line needs to be pigged. For instance, in plays with extremely wet and/or sour gas, the line from the wellhead to the centralized dehydration facility may need to be pigged multiple times per day. In such cases, installing an automated launcher can be a highly economical way of removing accumulated liquids and managing corrosion.

Another notable benefit of pigging is that it provides gas pipeline operators with a means of recovering valuable NGL. This has become particularly useful, as it has allowed companies to extract additional value from their liquids-rich gas streams.

When making a decision to install an automated pigging system, operators should consider not only the impact that it will have on their pipeline integrity management plan, but also the extent to which a more aggressive pigging schedule would improve throughput. In addition to operations employing centralized dehydration, an automated system can be applied in instances where large capital investments are not justifiable, as is the case with older pipeline infrastructure. In these situations, an automated pigging system can enable operators to cost-effectively maintain integrity and prolong the life of their lines, thereby avoiding the need to commission entirely new infrastructure.

Pipeline design and dispersion modeling. From 2009–2015, the rapid development of shale resources throughout North America led to a common trend whereby operators oversized their lines to accommodate future increases in production. However, with a steep decline in drilling activity following large drops in oil prices, many of these lines have been left with a great deal of spare capacity. This spare capacity often results in stagnant flow, which leads to a higher volume of liquids falling out of the stream and accumulating in the bottom of the pipe. These liquids raise differential pressure and contribute to corrosion. Although designing pipe with thicker walls at low elevation points provides added protection against leaks caused by fluid accumulation, it does not address the corrosion problem at its root and should not be used as a long-term solution.

Internal corrosion and unpredictable fluid formation can result in a higher likelihood of leaks and/or failure. For this reason, operators should account for both gases and liquids in their dispersion models. Doing so will aid in determining how liquids will flow over an area in the event of a pipeline rupture, allowing for the development of a more impactful emergency action plan. Liquid dispersion modeling is particularly important in operations exposed to cold environments—as the temperature drops, a higher volume of product release will be present in liquid form in the natural gas stream.

Conclusion. Over the past seven years, increased production from unconventional shale plays has spurred a significant rise in demand for pipelines and gathering systems. The increased trend of dehydrating gas at a centralized location away from the wellhead is a testament to the focus by operators on minimizing the costs associated with operating and maintaining those systems.

However, it is important for companies employing this option to understand that it does not come without added risk. Aggressive corrosion control techniques, such as automated pigging, are necessary to mitigate that risk. Such control techniques ensure the safe and efficient operation of mission-critical midstream infrastructure throughout its intended design life. GP

|

David Wint is the Director of Pipeline Integrity for Audubon Field Solutions. He has more than 30 years of technical pipeline experience in the oil and gas industry, specializing in corrosion control, pipeline integrity, regulatory compliance and pipeline pigging programs. In his present role, Mr. Wint leads Audubon Field Solutions’ pipeline integrity operations efforts. He earned a BS degree in mechanical engineering from the University of Tulsa and is a certified NACE (National Association of Corrosion Engineers) cathodic protection specialist.

Comments