Remove the gaps between planning, maintenance and operations

M. Neill, Petrotechnics North America, Houston, Texas

Domestic crude oil production is at levels last seen 25 years ago, and 2014 showed a record year for domestic natural gas production. Natural gas liquids (NGL) production in the lower 48 states recently hit 3.5 MMbpd. In spite of the challenging oil price environment, the US is awash with hydrocarbons. The US Energy Information Administration (EIA) projects strong production for decades to come. The resurgence of the US oil and gas industry is well underway. Many petrochemical operators are proceeding with projects to expand capacity, and several new LNG projects are nearing completion and preparing to commence export operations. The infrastructure to transport and process production to refineries, chemical plants and storage facilities is understandably stretched to cope with current and future throughputs.

With infrastructure at capacity, new construction already at a high pace, and aging infrastructure requiring constant maintenance and repair, gas processors are left with a dilemma. Operators must often manage the conflicting demands of operating and maintaining infrastructure while constructing new additions to minimize outages. Furthermore, operators must ensure that ongoing operations minimize conflicts and disruptions while demonstrating internal and external compliance.

Indeed, gas processors are tasked to achieve safe, efficient and sustainable operations. Competing priorities for work often challenge the ability to balance the needs of all functions within their organizations. Bearing that in mind, gas processors constantly juggle maintenance vs. production priorities. All too easily, operators can slip into a “fix-and-repair” mode vs. a “maintain-and-prevent” focus, where planned activities take a back seat to more urgent, corrective and breakdown work. This spiral can result in an insurmountable maintenance backlog, a vicious cycle of inefficiency that impacts the reliability of safety-critical equipment, which is paramount to maintaining the health of major hazard barriers. For these components, the deferment of inspections, calibrations and preventative maintenance impairs performance reliability and increases the risk of an incident escalating into a major accident.

As assets age, this becomes more critical, not only due to the lifespan of equipment but also to the change in demand on the facility. In these instances, risk to the operation escalates and can further manifest in terms of unplanned shutdowns, incidents, accidents, injuries and potential fatalities.

To ensure safe, efficient and sustainable production, operators must close the gaps between maintenance, planning and the operational reality of the plant. Through improved integration of planning, maintenance and operations, plant operators can better prioritize and select activities that have the lowest level of operational risk.

The hard facts. Improving operational performance and integrating planning, maintenance and operations can have tangible and positive impacts on the business. This can also be said for improving overall equipment effectiveness and decreasing the number of compliance citations. Improving these areas helps to ensure more efficient and profitable organizations. Companies in Soloman’s top quartile have less than 3% unscheduled downtime and have reduced their maintenance spending by up to 50%. Top performing companies proactively control operations and mitigate failure.

All of this is easier said than done without a complete picture of operational priorities and an integrated plan of all plant activities. Without a clear definition of enterprise-wide activity, decision-making is a functional, piecemeal process leading to inefficiencies and exposure to risk.

That said, many organizations tend to organize themselves functionally, with each function continuously striving to optimize its own business processes. For example, to improve planning tools and management, consultants are brought in to advise. Maintenance does the same thing with reliability-centered maintenance (RCM) and risk-based inspection (RBI) methodologies. Other groups, such as projects or utilities, often develop priorities independently and without consideration of how they may interact with each other. Operations also has plans that could, and frequently do, supersede the others. Changing a work plan into a safe work plan often means additional activities that may not have been considered when the schedule was developed. Sadly, when it comes to securing priority, it is often given to those that shout the loudest. The idiom “the squeaky wheel gets the grease” may not constitute a maintenance strategy, but it probably reflects operational realities.

Combating insufficient preparation. Independent consultant TA Cook conducted a maintenance efficiency study in 2013 that examined 170 companies around the world in asset-intensive industries. One of the conclusions was that 50% of maintenance efficiency losses are due to insufficient planning and work preparation. While much of the time spent to improve planning and work preparation initiatives is known, one of the key messages shared is that, without jointly defined objectives and a coordinated approach between maintenance and operations, improvements in planning and work preparation cannot be realized.

One survey looked into the percentage of planned work that operators and contractors actually achieved. The result was an astonishing 17%. While this may be a shocking number, it becomes believable when it is known that 83% of the time was not idle. Workers were active, but they were not following the plan and schedule. The result was very costly, and indicates that priorities were not being followed. Some companies in the upstream oil and gas segment estimate that they fall within the 25%–30% range, while some downstream and chemical industry operators estimate that their percentage could be as high as 65%. Significant room for improvement exists if planned activities do not take a back seat to more urgent, corrective and breakdown work, delaying scheduled work.

One study showed that an energy company’s actual operations and maintenance hours were triple its earlier estimates. Insufficient planning is expensive. If a company is structured the way its functions are set up, then the connecting points are not as clear. These processes are not necessarily linear. Indeed, there are many more that arise in day-to-day operations, and it is vital to better collaborate across all of the business’ functions.

Understanding operational risk. Even when attempts are made to develop an integrated plan and schedule, the day of execution can still bring failure. Operations are dynamic—things happen, equipment breaks down, logistics fall apart, personnel get sick and the weather is unpredictable. Priorities can change in minutes and hours rather than in days and weeks. This is where the conceptual plan meets the real world, and there are inevitable clashes. In these situations, employees need to make decisions quickly and deal with circumstances that arise on that given day. This is an area where the industry is prone to unseen levels of risk exposure.

Struggles to combat poor risk awareness and hazard identification, as well as gradual risk complacency outside of specific operational disciplines, are common. The gap between the plan and its actual execution requires an understanding of operational risk and how it will impact the frontline.

Operational risk is the combination of people, assets, the environment, reputation, health and major hazard risk, and it increases when there is a breakdown of internal procedures, people and systems. Process safety management programs have been developed to prevent major accident risk. Operational risk management is a key discipline of these programs. Barrier systems performance is crucial to keep volatile, flammable, explosive and toxic materials contained and to prevent escalation of any occurrence. Maintenance efforts are often involved in inspecting, testing, calibrating and performing activities to ensure the integrity of these safety critical elements (SCEs), or process safety management barriers. All too often, the inspection of SCEs gets deferred in favor of urgent repair work. Fixing what is known to be broken/damaged is often seen as a priority to searching for things that are broken. Unfortunately, the risk consequences of this type of thinking are not visible to many in the organization, and the tools for proper, unified assessment are not readily available.

Often, the industry struggles to make risk-based decisions on a day-to-day basis. Solid risk-based approaches for plant design may exist, but daily operations rely heavily on the frontline workforce to make decisions based on gut feel and experience. Attempts are made to define areas of high risk and write policy to manage specific scenarios. However, when these fall outside of reality and are left to the judgement of frontline personnel, the true risk exposure of these decisions is often unknown unless it results in an incident. It is imperative that plans are connected to operational realities and managed in a way that drives safe production.

Finding a solution. Integrating business processes to improve end-to-end management begins with a better understanding of operational risk. This enables the safe and cost-effective extraction of an asset’s maximum value.

A unified approach to assessing and managing risk across the business, whether that means management of change (MoC), mechanical integrity or competency risk, is documented in terms of its impact on daily operations. By developing a common currency of risk across the business and all of the functional groups, gas plant operators can identify how business priorities and work-related activities combine with plant conditions to impact the safety barriers that protect people, assets, facilities and their surroundings against major accidents. Well-managed companies prioritize operations in account of vulnerabilities.

With a simple instruction of “Fix the pump,” the entire organization can understand this as more than just an activity. Most likely, an isolation is associated with the job, as well as safety dependencies and other tasks and subtasks required to complete the job. While maintenance management systems might indicate that 6 hr are needed to carry out the work order, the reality is that it could take as long as 48 hr because needs include:

- Worksite preparation

- Pump isolation

- Pump flushing and sampling

- Confirmation that there was no spark potential from hydrocarbons or chemicals so hot work could be executed.

By not considering all facets in advance, it is difficult to know if the capacity exists to support the work because true understanding of the risks carried with plant conditions, plus all of the scheduled work, is lacking.

Refining the planning-to-execution management process. Gas operators need the right tools to manage risk and operations. Without those tools, a successful operation depends solely on competency and SMEs.

Operations excellence management software platforms offer improvements over traditional assessments of operational risk and the management of the complete planning-to-execution business process. With these platforms, plant operators see all operational risks across their businesses, the contributing factors to safety risks and their impact on process safety in one place, in real time. By aggregating this data, operators can identify risk within a specific area of the plant, across a unit and throughout an entire facility, over a specific duration.

By connecting plans with the operational reality of the plant, better decisions can be made to improve plan accuracy, plan attainment and wrench time, as well as manage and mitigate operational risk.

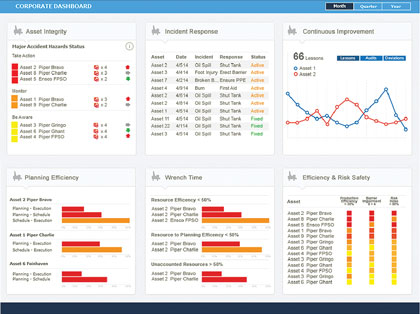

Dashboards present plant status in terms of risk, trends, peak exposure and more (Fig. 1). Icons on graphical screens show the area on the plant affected by impairments and deviations, and the cumulative impact on process safety barriers and activities that could contribute to an actual event. When combined with work execution, the elusive measure of productivity vs. safety risk exposure can be assessed.

|

|

Fig. 1. Icons on dashboard graphical screens show affected areas and the |

By connecting operations management and risk management, operators can better understand plant status in terms of risk, trends and peak exposure, and make proactive interventions to prevent major accidents.

Moving forward. To maintain efficient operations in this time of increased production and a surplus of low-cost feedstock, gas processors must:

- Employ a consistent and universal process across their businesses for risk awareness, assessment and mitigation

- Ensure a common understanding of operational risk across all areas of the business

- Engage in consistent metrics and KPIs for tracking and mitigating operational risk levels across the business

- Integrate planning, maintenance and operations to ensure visibility of the complete operation.

Emerging technologies may offer a path forward for operators to achieve safe, efficient and sustainable operations, identifying risk potential that arises from fluid day-to-day challenges and enabling plant operators, senior executives and the frontline workforce to maximize efficiencies while maintaining a safe plant. GP

|

Mike Neill is the president of Petrotechnics North America. With 35 years of experience in operations working for BP and throughout his career at Petrotechnics, he has improved safety and performance management for oil and gas organizations around the world. Mr. Neill is a member of the CCPS, AIChE, GPA, ASSE, AFPM, OESI and an active member of the Mary Kay O’Connor Process Safety Center steering committee.

Comments