Gas processing news

Bob Andrew, Technical Editor

New EU standard for paraffinic diesels

|

The European Committee for Standardization (CEN) on April 15 ratified the EN15940 standard for paraffinic diesel fuels, such as Shell's GTL fuel. Shell was involved in the nine-year consultation process, having first proposed the creation of a specification in 2007, before the largest GTL facility, Pearl GTL, came onstream in Qatar.

EN15940 will now create a standardized platform for markets to develop around paraffinic fuels. These 100% finished fuels can be used as drop-in fuels and have the potential to improve local air quality without the need for engine modifications or changes to existing fuel infrastructure.

Paraffinic diesel fuels are liquid fuels that can be synthetically manufactured from feedstocks such as natural gas (GTL), biomass (BTL), coal (CTL) or from hydrotreating vegetable oil (HVO). Shell GTL fuel is part of the emerging paraffinic fuel market, offering a cleaner-burning alternative fuel produced at Pearl GTL in Ras Laffan, Qatar, a partnership with Qatar Petroleum. This world-scale plant produces 140 Mbpd of GTL products, including Shell GTL fuel.

Shell GTL fuel can be used as a drop-in fuel in diesel engines without the need for engine modifications, new infrastructure or vehicle investment. It is virtually sulfur and aromatics free, readily biodegradable and nontoxic. Shell GTL fuel also helps reduce local emissions of nitrogen oxides and particulate matter.

Paraffinic fuels do not fully meet the EN590 specification because they have slightly lower density. However, paraffinic fuels now offer significantly improved and favorable fuel properties. They compensate for their low density with higher energy content and higher cetane number. Also, the higher consistency of the fuel molecules mean that they combust more uniformly in diesel engines compared with conventional refinery diesel, resulting in lower emissions.

Shell has conducted several field trials on Shell GTL fuel in major cities around the world over the past decade, covering over 1 MM km. Key market segments for Shell GTL fuel include city utility vehicles, public transport, inland and seagoing marine vessels, construction machinery and vehicles, power generation equipment, aviation ground fleets and rail.

Overhaul of Swedish gas generators

Svenska Kraftnät Gasturbiner AB (SvKGT) has awarded RWG a multi-engine contract for overhaul, re-installation and commissioning of Siemens Industrial Avon gas generators operating at a power station located in southern Sweden.

This contract forms part of Project GINST, SvKGT’s gas turbine investment program. Project GINST is an initiative to rehabilitate disturbance reserve power generation capacity supporting Sweden’s national grid. This initial phase involves the overhaul of four gas generators installed at SvKGT’s Lahall power station, but with an option to extend the work over the next four years to encompass all 24 gas generators at SvKGT’s Lahall, Hallstavik and Arendal stations. The scope of this contract includes RWG’s field service support for installation and recommissioning of each gas generator.

MEG joint industry project

A Norwegian firm’s research into cleaner technologies for the oil and gas industry has been recognized with the award of an innovation grant to develop the next generation of MEG regeneration systems. The Research Council of Norway chose Fjords Processing’s Mono Ethylene Glycol (MEG) joint industry project (JIP) for funding.

The 3.6-MM-NOK funding support from the council’s leading DEMO 2000 program will enable Fjords Processing to collaborate with Statoil, Shell, Total and Chevron to target qualification of the patent-pending technologies that could deliver a new generation of greener, more efficient and operationally stable MEG plants. The JIP aims to find ways of enhancing the current design of MEG systems by developing technologies to remove organic acid salts, hydrocarbon and mercury from existing and future MEG plants.

Fjords Processing believes further development of anti-solvent-based technology for the removal of organic acid salts will precipitate and separate salts, and also help regenerate anti-solvent for reuse. Technologies for hydrocarbon and mercury removal from MEG streams may also be qualified on a pilot scale.

Once testing is successfully completed, the results will then be used to develop and qualify key new offerings within greenfield as well as brownfield projects. Potential advantages from the results of the JIP are expected to include improved stability of plant operation, an overall reduction in MEG loss, and reduction in hazardous waste resulting from mercury and hydrocarbon discharge.

All gains will allow longer operation and reduction in operating expenditures for the participating operators. Reducing the overall environmental footprint of MEG systems may be safer for the ecosystem and operations personnel. Fjords Processing and its partners would support other industry operators to join the JIP, which is on course for completion in 2Q 2018.

Finland debuts LNG-powered icebreaker

|

The new Finnish LNG-powered icebreaker Polaris left on its first sea trial from Arctech Helsinki Shipyard on April 22. The trial is part of the test use of the ship, which is done to ensure the functionality of the vessel before delivery.

The main purpose of the vessel is icebreaking and assisting of vessels in ice conditions, but it will also be able to perform oil spill response operations, emergency towing and rescue operations under demanding conditions at open sea throughout the entire year. The ship has been designed for 50 years of service life.

New CNG service stations for UPS

TruStar Energy was awarded a contract to build 12 additional CNG fueling stations for UPS. TruStar will also maintain and service the stations under a long-term maintenance agreement. UPS plans to add 380 new CNG tractors to its growing alternative fuel and advanced technology fleet. The CNG fueling stations, vehicle purchases and CNG infrastructure totaling $100 MM are part of UPS’s ongoing commitment to diversify its fuel sources and reduce its environmental impact.

The new stations will be built by TruStar in Amarillo, Chattanooga, Columbia, El

Paso, Fort Worth, Kansas City, Phoenix, Reno, San Antonio, Tifton, Trinidad and Willow

Grove. The new CNG tractors to be deployed in these cities will be manufactured by Kenworth. Agility and Quantum Fuel Systems will provide the CNG storage systems. This investment builds on the company’s existing 18 CNG fueling stations in Alabama, California, Colorado, Georgia, Kansas, Kentucky, Louisiana, Oklahoma, Pennsylvania, Texas, Virginia and West Virginia. UPS operates CNG vehicles in Germany, the Netherlands and Thailand. In 2015, TruStar Energy built 15 CNG fueling stations for UPS.

License of low-global-warming refrigerant

|

Honeywell has entered into a supply agreement and technology license to produce Honeywell Solstice yf, an automobile refrigerant with a global warming potential (GWP) of less than 1.

Honeywell will license its technologies to produce the refrigerant to Navin Fluorine International Ltd. (NFIL), which will manufacture Solstice yf in India exclusively for Honeywell. Small-scale production is expected to begin by the end of the year.

Solstice yf, also known as HFO-1234yf, is a next-generation hydrofluoro-olefin (HFO) refrigerant that is a near-drop-in replacement for R-134a, a hydrofluorocarbon (HFC) with a GWP of 1,300, for use in in vehicle air conditioning systems globally.

Honeywell and its key suppliers are investing approximately $300 MM to increase global production capacity for Solstice yf, including the construction of a new, world-scale manufacturing plant at the company’s existing Geismar, Louisiana refrigerants manufacturing site.

The demand for Solstice yf for use in mobile air conditioning is increasing due to policies aimed at reducing the global warming impacts of HFCs. These include:

- The US EPA has approved Solstice yf for use as a low-global-warming replacement for R-134a, banned in new passenger cars and light-duty trucks starting in model year 2021.

- The EU MAC directive is aimed at reducing air conditioning greenhouse gas emissions in passenger cars and light commercial vehicles. Refrigerants in all new vehicle types sold in Europe after Jan. 1, 2013 must have a GWP below 150, and all cars sold in Europe after 2017 must meet the new GWP requirement of less than 150.

Primus launches methanol project

|

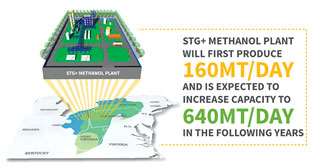

Primus Green Energy Inc., a GTL technology and commercial solutions company that transforms methane and other hydrocarbon gases into methanol and gasoline, announced plans to develop and deliver its 160-metric-tpd methanol plant to a manufacturing site in the Marcellus shale region. Production from the plant is slated to begin in 2017 for regional distribution, and three additional trains in the following years are expected to increase its capacity to 640 metric tpd.

Primus’ standardized modular GTL systems will convert low-cost Marcellus natural gas feedstock into methanol locally, thereby saving its clients in the region both production and transportation costs. As a result, the systems are cost-competitive with the world-class methanol plants located on the US Gulf Coast and in international markets. The company plans to deliver up to four additional methanol plants in other North American regional markets, with capacities ranging from 160 metric tpd to 640 metric tpd, which will follow its low-cost standardized design and facilitate local production.

Primus’ STG+ technology can use a range of natural gas feedstocks, including wellhead and pipeline gas, dry or wet associated gas, “stranded” ethane, excess syngas from underutilized reformers or mixed NGL. The systems’ stranded and associated gas applications offer a solution to the lack of traditional natural gas pipeline infrastructure in remote locations, enabling the monetization of gas that would otherwise be stranded or flared. The low-cost modular systems can be trucked in and assembled onsite for easy deployment.

The Primus STG+ methanol and gasoline solutions are being developed in multiple projects across North America, Asia and the Middle East. The process holds key advantages including low capital and operating costs, high liquid product quality, zero wastewater, process simplicity and a high conversion yield. These advantages result in STG+ technology reportedly being economical at all scales, starting as small as 5 MMscfd of feed gas.

World’s first FLNG receives equipment

|

ABB has won a five-year contract to deliver equipment and services for Shell’s Prelude FLNG, the world’s first floating LNG ship and the largest floating facility ever built. ABB’s equipment reportedly will minimize downtime and optimize the efficiency of the facility.

The order includes the delivery of motors, generators, variable speed drives and low-voltage switchgear. It guarantees service and lifecycle management of the electrical equipment as well as service and support for motors from third-party vendors.

ABB will build up a spare parts inventory, make workshop repairs, and provide training and onsite and remote technical support. Spare parts and replacement systems are being procured this year, with training to begin in the near future.

Prelude is 488 m long and 74 m wide, with a loaded displacement of 600 Mt and a deck longer than four football fields laid end to end.

Once towed to its location off the northwest coast of Australia, it will be attached to the underwater infrastructure in the Browse basin. It is scheduled to remain there for up to 25 years without uncoupling for overhaul, or taking shelter from cyclones.

Permian basin NGL recovery

Honeywell UOP will provide a modular Russell cryogenic gas processing plant to help EagleClaw Midstream Ventures recover NGL in the Permian basin. EagleClaw is focused on developing midstream infrastructure opportunities in the Permian basin of West Texas and Southeast New Mexico.

The skid-mounted modular plant will be shipped via truck to EagleClaw’s East Toyah plant from Honeywell UOP’s manufacturing facility in Tulsa, Oklahoma. When it enters operation, the unit will be capable of processing 200 MMscfd of natural gas to extract NGL.

Modular gas processing plants allow midstream gas companies to expand incrementally as feed volumes increase over time using parallel processing trains, and to upgrade facilities with additional processing capabilities or to adapt to changing feedstocks and product slates.

The Honeywell UOP Russell equipment is designed to enhance the competitiveness of both the natural gas stream producer and the midstream service provider.

More than 100 Honeywell UOP Russell modular cryogenic units are in operation in North America.

Comments