New in gas processing technology

BOB ANDREW, Technical Editor

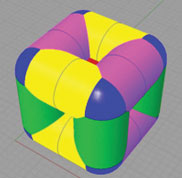

ABS approves LNG containment concept

|

International classification society ABS granted approval in principle (AIP) to US-based Altair for its Cubic Donut Tank System (CDTS) LNG containment concept. The tank system design is claimed to deliver increased cargo capacity while reducing loading and sloshing risks.

The concept is adapted from a patent filed nearly 40 years ago. The principle behind the initial design concept is the construction of a near-prismatic shape using 12 interconnected cylinders to create the structural efficiency of a spherical tank and the volumetric efficiency of a membrane tank.

According to Altair ProductDesign, the CDTS retains the advantages of the original concept, including greater relative cargo capacity than either a spherical or membrane containment system.

www.eagle.org and www.altairpd.com

New cryogenic valve range

Parker Bestobell Marine (PBM) will debut its new range of high-pressure marine valves for fuel gas systems at LNG18 in Perth, Australia in mid-April.

PBM has supplied its cryogenic globe valves to over 50 LNG fuel gas projects, including the Harvey Gulf offshore vessels being built at Trinity Shipyard in Louisiana. These ships are the first LNG-fueled vessels to be built in the US.

The company will also be demonstrating its new Compact Float Isolation Valve (FLIV) at LNG18. The compact FLIV, which is 150 mm in diameter and only 600 mm high, was developed to cater to the use of smaller-diameter floats.

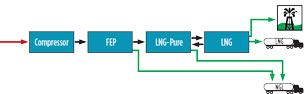

Motor fuel-grade LNG

|

Aspen Engineering Services offers a solution to produce high-purity LNG from rich natural gas. The LNG-Pure process produces motor fuel-grade LNG and NGL from rich, associated natural gas. The residue gas is used to power drilling equipment or produce electrical power, thereby providing a total flaring solution for stranded gas produced from shale oil production.

The patent-pending LNG-Pure process is a new process to the industry. A unique heat-integrated reboiler absorption system controls ethane prior to cryogenic liquefaction. Concurrently, no propane or heavier components enter the cryogenic equipment. The LNG-Pure process offers the following features:

- Motor fuel-grade LNG and NGL is produced from rich natural gas

- The ethane composition of LNG and NGL can be controlled to any level

- No additives or glycol systems are required to prevent freeze-up

- A small molecular sieve bed is adequate because the bulk of the water is removed by the flare elimination process

- No turboexpander is required

- Compression and cryogenic systems are cost-effectively integrated into front-end cleanup

- The process provides a flaring solution for shale oil production.

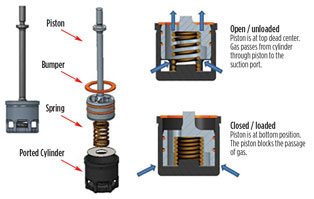

New unloader valve for reciprocating compressors

|

Zahroof Valves Inc.’s ZVI unloader valve is a patent-pending piston-style unloader, designed to improve reliability over traditional finger-style unloaders, and it features a much lower added clearance volume compared to plug-style unloaders.

Setting the ZVI unloader valves apart is the ability to service them in the field without additional machining. It is a reliable unloader, as there are no fingers acting against a dynamic valve element. Unlike a plug-type unloader, a large increase in clearance volume does not occur in the cylinder to detrimentally affect the compressor throughout. The flow through the unloader is said to be better than in the case of the plate or channel valves, improving unloaded power as well as eliminating drag forces and aerodynamic flutter of valve elements. The new unloaders do not have the misalignment/assembly issues of plug-style unloaders. The actuation force required for the ZVI unloader valve is less than that required for a plate, channel or plug-style unloader.

It is possible to replace multiple existing unloader systems at a corner of a cylinder with a single ZVI unloader system, utilizing regular suction valves in the other locations. The ZVI unloader valve can be used in all brands of compressors, at any speed, for both lubricated and non-lubricated cylinders. It can be used with virtually any gas where the maximum differential pressure across the unloader is up to 1,500 psi.

Design of the unloader system for a specific application is backed by analysis and simulation using ZVI’s Dynamic Compressor Simulation program. The ZVI unloader reduces down time, maintenance costs and improves efficiency.

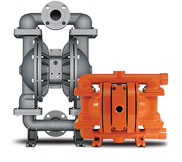

Gas-operated pumps

|

Wilden announced the release of a new line of CSA International-certified natural gas-operated double-diaphragm pumps. Specifically designed for the oil and gas industry, these new pumps are certified by CSA International to be used in applications where natural gas is the energy source to drive the pump.

For upstream and midstream applications, Wilden natural gas-operated pumps are available in clamped, bolted and Advanced FIT models. They come equipped with either the patent-pending Wilden Pro-Flo SHIFT Air Distribution System (ADS).

The pumps also comply with all CE and ATEX requirements, and feature extreme shear sensitivity, high-viscosity handling, dry-run capability, superior anti-freezing and no dead-head damage. Maximum flowrate is 246 gpm for the 3-in. model, and maximum discharge pressure is 100 psig for all models. Wetted paths are aluminum or stainless steel.

GTI predictive technology upgrade to VibePro 7.3

A major update is available to GTI’s vibration analysis application for iPad, with features requested by users. It provides a solution to performing vibration analysis on the iPad.

Time wave form support is now available. Users can record from 1 sec to 6 sec. Also added is the ability to rearrange the machines in the route. This much-requested feature took much engineering time to rewrite. A simple “tap-and-drag” feature allows the user to reorganize the order of the machines. Also new in version 7.3 is the ability to mass-archive measurement data.

Other new features include:

- Option to manually enter start/end frequency values in spectrum

- Added overall window calculation to user-selected frequency spectrum

- Performance enhancements.

Exchanger gaskets gain accreditation

|

Flexitallic has received industry accreditation for its unique Change gasket, as utilization of the product continues to increase in critical customer applications.

Change is a resilient metal-wound gasket designed to deliver a dynamic seal, with a claimed track record of performing 60% longer than other gaskets for the same application. The Change gasket exceeded the TA Luft pass threshold of the German air pollution regulation by four orders of magnitude, demonstrating the technology’s ability to deliver the tightness of a Kammprofile with the memory (recovery) of a spiral-wound gasket.

With over 10,000 applications of the Change gasket already in service, it has improved a bolted connection performance for operations in steel, power, chemical and refining, in both standard-flange and specialty-equipment applications.

Change gaskets were introduced by Flexitallic in response to customers’ long-term heat exchanger sealing problems. Heat exchangers often undergo multiple temperature and pressure cycles, and poor long-term sealing can hurt overall operational performance. From these initial applications, customers have also applied the dynamic recovery technology to standard flange gaskets for improved long-term joint tightness.

Manufactured using proprietary equipment, the Flexitallic Change gasket features a metal spiral profile compared with standard gaskets. This profile, combined with a laser welding process, facilitates the construction of a robust and dynamic seal.

Change gaskets can also be supplied with Flexitallic’s Thermiculite gasket material, which was developed for use in critical services applications, from cryogenics to temperatures in excess of 1,000°C. Thermiculite material is a critical component in eliminating graphite oxidation, which limits seal life and seal tightness.

The company notes that the TA Luft test supports the decision of a growing number of customers, across a wide range of markets, to utilize the product. With growing sales, applications in problem bolted connections, and a growing product material and size range, the market is supporting the functionality of Change, and the latest accreditation will help continue this growth.

Comments