What’s new in gas processing technology

H. Meche, Associate Editor

Compression system for multi-fuel ships

|

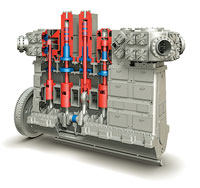

Burckhardt Compression has received a number of orders for its Laby-GI compressor system for fuel gas supply. The vibration-free reciprocating compressors will be installed on several LNG tankers with a carrying capacity of 174,000 m3 each. The tankers will be used to deliver fuel gas to ship engines and auxiliary power units, and also to reliquefy boiloff gas.

The propulsion system can be operated with eco-friendly natural gas or with heavy fuel oil. Demand for such efficient and low-emission propulsion systems is increasing as a result of stricter environmental regulations.

The Laby-GI compressor system is said to be the most flexible and robust fuel gas supply solution for dual- or tri-fuel ship engines. It delivers fuel gas derived from boiloff gas (LNG vapors) to a ship’s dual-fuel engines. As a multipurpose system, the design helps minimize the complexity, footprint and weight of onboard installations.

Burckhardt Compression’s Laby-GI fuel gas compressor system, developed in close collaboration with diesel engine manufacturer MAN Diesel & Turbo, can be used in a range of propulsion systems. It ensures a stable supply of fuel gas in any condition, regardless of changing ambient conditions (e.g., engine load or gas temperature, pressure or composition).

Exchanger technology for air-cooled LNG facilities

|

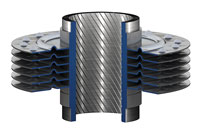

GEA Batignolles Technologies Thermiques, Wieland Thermal Solutions and Technip have developed a new technology to boost efficiency for air-cooled LNG facilities. Dual internally and externally structured tube for air coolers (DIESTA) combines two established technologies for the outside and inside of a tube, the key component of an air cooler.

For this development, Technip (the EPC company) and Wieland Thermal Solutions (specialists in heat transfer) collaborated with GEA Batignolles Technologies Thermiques (air fin cooler and heat exchanger provider).

DIESTA technology typically allows a 2% to 3% increase in LNG production, while taking advantage of compression power savings. In addition, the compact design reduces the equipment footprint by up to 20%. Finally, the reduction in specific fuel gas consumption lowers CO2 emissions.

Ball valves for cryogenic applications

The SVF Series K8 family of valves is available from stock in a range of sizes from 0.5 in. to 2 in. All valves are pressure-rated to 2,000 water/oil/gas (WOG) and feature built-in ISO-5211 direct-mounting pads for easy and robust mounting for automation. The valves are available with screwed ends, socket-weld ends and No. 150 raised-flange ends.

Series K8 valves are produced with polychlorotrifluoroethylene (PCTFE) seating material

for cryogenic applications. Additional information on the cryogenic ball valves from SVF Flow Controls can be found in the engineering resource section of the company’s website.

One system for dual dewpoint analyses

|

Michell Instruments’ established hydrocarbon dewpoint analyzer and its latest generation of tuneable-diode laser-spectroscopy moisture analyzers are now available in a single package to help gas companies ensure the quality of their pipeline transmission gas.

The Condumax II hydrocarbon dewpoint analyzer and the OptiPEAK TDL600 analyzer are combined in one system to provide users with the benefits of both systems, in an easy-to-install package. With a smaller footprint than two analyzer systems, the unified system reduces costs and saves space.

The package includes both analyzers and a combined sample-conditioning system to ensure a steady sample flow, which is at a uniform pressure and temperature. It is fully certified for installation in hazardous areas worldwide, with certifications from ATEX, cCSAus and IECEx.

System provides continuous gas supply

|

AURA Controls’ AURA EXD series automatic differential-pressure switchover system is designed to provide a continuous supply of high-purity gas in critical applications and in demanding process environments.

The system is claimed to be a good fit for carrier and calibration gas delivery applications used in chromatography processes, sampling systems and laboratory instrumentation.

The switching technology uses a priority valve assembly to provide failsafe operation, allowing end users to replace depleted gas containers without system interruption and increasing time between changeouts. Cylinder economy and flowrate are also maximized.

With its fully configurable inlets, the AURA EXD system has the flexibility to fit the application-specific requirements of fittings, purges and isolation valves for inlet pressures up to 3,000 psig. AURA EXD regulators are available in delivery ranges

up to 350 psig with 4-in., 12-in. and 24-in. panel options.

LNG solution with standardized packages

|

Jereh’s Playwell Micro LNG solution is available in four standardized packages to achieve LNG production capacity of 1 MMscfd, 2 MMscfd, 4 MMscfd and 6 MMscd, ensuring a 20-week project period and thereby saving 60% in project cycle and 20%

in project costs.

The solution’s packages can have wider applications for coalbed methane, pipeline gas, shale gas and boiloff gas liquefaction. All modules are designed in a compact skid-mounted structure with standardized equipment, including an Ariel compressor and a Caterpillar engine. For liquefaction processes, the solution offers advanced single-mixed refrigerant (SMR) nitrogen (N2) expansion and precooled mixed refrigerant (PCMR) processes for better production efficiency.

In addition, standardized packages will bring bulk purchasing and production, so cost will decrease when the solution is widely applied. An intelligent remote control system achieves real-time data acquisition by mobile phones and other terminals, offering easier and safer onsite operation with lower labor costs.

Particulate filtration raises turbine efficiency

From its Dollinger brand, SPX provides a wide range of precision-engineered air intakes, fuel gas and fuel oil filtration packages, along with oil exhaust eliminators. The Dollinger series GP-146 high-efficiency gas particulate filters are designed to remove final traces of dirt, pipe scale and other solid contaminants from process air and other gases.

In addition to cleaning the fuel gas stream entering a turbine, they can also be used in any gas pipework system to prevent contaminants from damaging instruments or equipment.

Unlike conventional multi-candle filters, the Dollinger element design concept maximizes the effective filtration area for a given vessel size. Dollinger also offers customized filter designs and capacities to suit particular process and application demands.

Most of the filters are constructed in carbon steel or stainless steel. However, they are also available in duplex, super-duplex and other high-quality materials where required. Special requirements for low-temperature applications can also be accommodated.

The Dollinger GP-146 filter’s efficient radial-fin-element design provides the largest filtration area for a given element size. This increases dirt-holding capacity, minimizes pressure drop and results in an extended service life.

The filter element support structure is constructed from steel suitable for the particular application. Standard element design ensures its integrity up to differential pressures of 3.45 bar and beyond, with special bespoke designs available where required.

New CNG gas tank

Quantum Fuel Systems Technologies Worldwide has developed a 5,000-psi tank for the CNG virtual pipeline market. The tank was developed to transport CNG in bulk quantities to locations where pipeline infrastructure is nonexistent. The 640-l tank was designed to maximize the transport density of natural gas at 5,000 psi.

Versatile process diaphragm pumps

|

The Lewa G3M heavy-duty, medium-sized triplex-drive unit was originally developed to bring reliquefied boiloff gases from LNG tankers to a high-pressure level, rendering the gases usable for ship propulsion systems. The G3M unit attains a maximum output of 200 kW due to its 120-mm stroke length and 125-kN rod force.

Primarily intended for the oil, gas and chemical process industries, the unit can manage pumping tasks for pressures between 40 bar and 750 bar. Applications include injection of monoethylene glycol and methanol, high-pressure metering of liquid ammonia, and handling flammable materials (such as vinyl acetate) and slurry in wet oxidation.

Like other Triplex series models, the G3M unit is equipped with an integrated, heavy-duty worm gear. The mono-block drive-element housing, on which the electric motor is flange-mounted via a coupling with a flexible intermediate element, minimizes the required number of bearings and seals. The optimal phase offset of the three pistons is ensured by a one-piece, solid- and triple-throw crank shaft, requiring only two roller bearings.

To attain better damping of the swelling load, the bearings of the connecting rods are designed as slide bushings. A frequency converter regulates change of motor rpm, number of strokes per minute and the flowrate. All drive-unit components are designed for continuous duty, enabling problem-free operation for more than 40,000 hours.

Lewa is developing pump heads for every conceivable application to fit the G3M unit, relying on existing, proven technologies so that the pump can be adapted for use in many application situations. Even high-pressure applications will be possible with the M800 pump heads, because these heads on the G3M drive unit with a polytetrafluoroethylene diaphragm are designed for up to 750 bar.

Unmanned FLNG concept reduces costs

|

DNV GL’s new unmanned floating LNG concept, called Solitude, reportedly overcomes many of the challenges faced by those looking to unlock the potential of remote offshore gas fields.

Solitude makes use of advanced but mainly available technology to provide its power. This power, which would otherwise be generated by high-maintenance gas turbines, can, for example, be generated by fuel cells, improving power generation reliability and reducing the unit’s environmental footprint.

The FLNG’s equipment is modularized and monitored from shore. Much of the routine maintenance and fault correction is carried out by self-programming autonomous inspection and maintenance units (robots), which run along a system of rails on each process train on the topside, allowing access to all equipment.

Wireless sensor networks act as eyes, ears and noses, feeding information to a condition monitoring system that oversees fault detection, proactive maintenance and repair planning.

As there will be no one living onboard or working on the topside during normal operation, associated personal safety risks are eliminated.

When people do enter for large maintenance campaigns, the topside would be prepared for a safe working environment. The FLNG’s new support and accommodation vessel concept and its associated docking system further boost the safety of interventions.

Couplings for turbines, compressors

|

Voith acquired Albert Hirth’s patent for a positive locking connection between shafts and wheels over 50 years ago. Developed at the beginning of the 20th century, the Hirth coupling is still viable today, and Voith manufactures a coupling with a diameter of up to 1,600 mm and 720 teeth.

Gas turbines and turbocompressors are subjected to extreme loads, and they must ensure maximum reliability despite high pressures and extreme temperature differences. Hirth couplings are used between gas turbine disks or as connections between the impeller and the pinion shaft.

The couplings are said to ensure high precision in both axial runout and concentricity, and they reduce the load on the bearings due to their precise, reproducible centering. The couplings also reduce the rotating mass in comparison to force-fit flange connections.

Shafts and their seals in the driveline of coolant pumps must be regularly maintained. Hirth couplings provide the option of combining several shaft segments into arrays of up to 5 m in length. It is more cost-effective to manufacture the small segments; they can also be assembled very quickly or removed individually.

Hirth couplings guarantee concentricity precision of > 0.05 mm, even in arrays, and they retain the original balance, even after being disassembled several times.

Cargo simulator expands capabilities

GTT Training has increased the capabilities of its LNG Cargo Operations Simulator, which is used to provide hands-on, real-time training for LNG cargo-related processes and procedures.

The simulator mimics all vessel systems involved in LNG cargo management and handling, as well as the systems involved in maintaining vessel safety. Expanded capabilities enable instructors to select from 16 different LNG carrier configurations, with selection based on tank capacity and containment and propulsion systems.

The simulator uses accurate mathematical models for each of the ship configurations, providing a realistic experience for operators. It can deliver a full range of courses, from detailed problem solving for senior personnel to basic familiarization for industry newcomers.

Laser-based analyzer measures five in one

|

NEO Monitors’ LaserGas iQ² product is said to be the first all-in-one tunable-diode laser analyzer for in-situ measurement. It measures four gases (O2, CO, CH4 and H2O) and temperature in one unit, eliminating the need for multiple process analysis units. Previous analyzers have, at the most, been able to measure two process components.

The LaserGas iQ² solution will enable users to optimize and increase their control over its processes. They will be able to better comply with process regulations and increase safety through better knowledge of gas concentrations and temperatures inside stacks. Identification of faults and errors will be quick and precise.

The analyzer can solve application needs relevant to FCC units, package boilers, process heaters, electrostatic precipitators, vinyl chloride monomer waste gas recovery, reformer gas, incineration and more.

By providing a design for three configurations with one transceiver, customers may replace existing zirconia-style probes or extractive-type point analyzers, and reduce installation costs.

Other benefits include the handling of typical process control up to 1,200°C, increased absorption signal for low concentration through double path length, reduced operating and maintenance costs compared to other technologies, flexibility in introducing new gases and combinations, and more.

Compressors for low-volume applications

Compact Compression Inc.’s Hydraulic Casing Gas (HCG) line of solution gas compressors has a new compression element specifically for low-volume-solution gas applications.

The new HCG compressor is designed to process liquids, so there is no possibility of liquid lock. The compressor is also independent of the pump jack, so both the pump jack and the compressor can be individually managed to maximize oil production.

After two years of development and successful field testing, the company has started large-scale production of the HCG compressor.

Comments