Gas processing news

H. Meche, Associate Editor

Process unlocks code to leverage shale gas

For the last three decades, chemical companies worldwide have been working to develop a process to convert methane into ethylene. In April 2014, IHS Chemical issued a research note discussing the Siluria process, which is claimed to produce ethylene directly from natural gas through oxidative coupling of methane (OCM).

With the startup of Siluria’s new demonstration plant in La Porte, Texas on April 1, the technology moved one step closer to reality. According to IHS Chemical’s 2014 process economics report, which assessed the potential commercial viability and economics of this new technology, IHS analysis said that Siluria appears to have developed a patented process for producing polymer-grade ethylene via OCM.

With the demonstration project in place, this announcement is timely for producers seeking to further leverage the abundance of shale gas resources available in North America and other regions for the manufacture of petrochemicals.

The IHS report, “The IHS Chemical Process Economics Program: Review 2014-07, Oxidative Coupling of Methane (OCM) to Ethylene by Siluria Process,” reviews the design and relevant economic performance of an ethylene plant based on Siluria’s OCM technology. At present, ethylene is predominantly produced using high-temperature steam cracking of ethane and naphtha feedstocks.

Siluria has partnered with Linde to offer licenses to the ethylene industry worldwide. Siluria estimates that, at a 1-metric MMtpy scale, its technology would have a $100/t cost advantage over ethane cracking and a $350/t advantage over naphtha cracking. IHS estimates the ethylene cash cost to be $515/t when methane is $4.12/MMBtu.

Siluria has also scaled up production of the catalyst. CAPEX for the 1-metric tpd OCM demonstration plant is $15 MM. Siluria is working with Linde to offer design for methane-to-ethylene plants with capacities of 75 metric Mtpy to 1 metric MMtpy.

Robot repairs gas lines without disruption

|

US-based ULC Robotics has deployed its Cast-Iron Joint-Sealing Robot, called CISBOT, for the first time in Scotland, on Edinburgh’s iconic George Street. In conjunction with UK gas distribution network SGN, CISBOT will carry out advanced maintenance on more than 1,965 ft of gas pipe that delivers gas to businesses and residents in one of Edinburgh’s most high-profile and central locations.

Unlike traditional methods of rehabilitating or replacing cast-iron gas mains, ULC’s CISBOT enters the live, large-diameter cast-iron gas mains through a small excavation. With advanced technology, the robot can repair joints while minimizing disruption to the public.

Performing nonintrusive work on live gas mains means that the gas services of many businesses along the street remain intact and online during the procedure. In addition, the work done with ULC’s CISBOT technology reduces the risk of gas leaks. With no large-scale excavations, greenhouse gas emissions are reduced.

In addition to the George Street project, ULC Robotics performs year-round operations for SGN, and now has two CISBOT systems dedicated to the gas utility’s field operations.

Valve maker expands further into China

|

Bestobell has a new contract to supply cryogenic valves to Zhuhai City Gas Pipeline Co. Ltd. in Zhuhai City, China. Bestobell will manufacture emergency shutoff valves, globe valves, pressure regulators and check valves for the Zhuhai Qianshan LNG storage station, which has a capacity of 20 MNm3/hr of natural gas.

This latest order takes the total number of Chinese storage stations using Bestobell’s valves to more than 20, helping the company secure its position as a major supplier of cryogenic valves for land-based projects in China.

Zeolite catalyst permits partial methane oxidation

A research team combining the expertise of Moniek Tromp (University of Amsterdam/HIMS), Evgeny Pidko and Emiel Hensen (Eindhoven University of Technology), Maricruz Sanches-Sanches (Technische Universität München) and Johannes Lercher (Technische Universität München and Pacific Northwest National Laboratory) might be paving the way to small-scale GTL technologies, converting natural gas to fuels and starting materials for the chemical industry.

The team has focused on a modified zeolite (a highly structured porous material) developed by Professor Lercher’s research group in Munich. This copper-exchanged zeolite with a mordenite structure mimics the reactivity of an enzyme known to efficiently and selectively oxidize methane to methanol. It mimics the active site of the enzyme methane monooxygenase (MMO), and the zeolite’s micropores provide a confined environment for the highly selective stabilization of an intermediate copper-containing trimer molecule.

According to Professor Johannes Lercher, the developed zeolite is one of the few examples of a catalyst with well-defined active sites evenly distributed in the zeolite framework—a truly single-site heterogeneous catalyst, allowing for much higher efficiencies in converting methane to methanol than with previously reported zeolite catalysts.

The research also showed the unequivocal linking of the structure of the active sites with their catalytic activity, rendering the zeolite a “more than promising” material in achieving levels of catalytic activity and selectivity comparable to enzymatic systems.

Technology transforms gas into gasoline

Air Liquide Global E&C Solutions has a global technology licensing agreement with ExxonMobil Research and Engineering, under which Air Liquide will market and license its proven Lurgi MegaMethanol technology in combination with ExxonMobil’s proprietary methanol-to-gasoline (MTG) technology. The combined technologies will be marketed under the trademark G2G to transform natural gas and other feedstocks into motor gasoline containing virtually no sulfur and a low amount of benzene.

The integration of both technologies into one combined solution will minimize project interfaces, offsites and logistics complexities, as well as overall investment for synthetic fuel production. The G2G technology will be licensed as an integrated solution and will be deployed globally through Air Liquide Global E&C Solutions’ network.

Air Liquide Global E&C Solutions has signed nearly 20 licenses for its Lurgi MegaMethanol technology since 2000, with acceleration over the last 18 months.

ExxonMobil’s MTG technology selectively converts methanol to ultra-low-sulfur gasoline. The first plant using the technology operated in New Zealand from 1985 until 1995.

Terminal to use Honeywell technologies

|

The automation and security systems of Honeywell Process Solutions (HPS) will help Freeport LNG Development LP expand its southeast Texas LNG terminal into a major liquefaction and export operation. The terminal, located on Quintana Island near Freeport, Texas, will see the construction of three new processing units as part of a more than $13-B expansion, adding gas pretreatment and liquefaction capabilities. This expansion will give Freeport LNG 13.9 MMtpy of export capacity, with startup expected in 2018.

HPS will be the expansion project’s integrated main automation contractor (I-MAC), responsible for designing, delivering and installing the automation, instrumentation, controls, and safety and security systems. The unified approach will be critical in helping the project meet operational and business readiness goals on Day 1 of startup.

Honeywell will go beyond the traditional main automation contractor role to include a broader scope of products, services and consulting capabilities that add value over the entire project and operating lifecycle of the venture. Specific key deliverables include LEAP—Honeywell’s lean project execution services, Experion PKS Orion with Distributed Systems Architecture (DSA), Experion Security Integrator, Fault Tolerant Ethernet (FTE), Universal process and safety I/O, virtualization, advanced control, safety manager, fire and gas systems, OneWireless Network, Digital Video Manager (DVM), a UniSim operator training simulator, advanced alarm management software and a PHD data historian.

Software improves combustion visualization

Through a multi-year joint-development agreement, GE and Palo Alto-based Cascade Technologies Inc. will apply and improve simulation software to enable engineers to virtually look inside a gas turbine as it operates and gain a better understanding of the turbulent fluid, chemical and acoustic processes occurring within advanced, low-emissions gas turbine combustion systems.

Compared to other digital modeling techniques, Cascade simulation software is said to enable improved combustion process visualization so that engineers can better comprehend the occurrence of subtle changes.

Visualization is enabled via code software that can be scaled to run on national laboratory super-computers and at other high-performance computing facilities. The code allows GE and Cascade teams to simulate the combustion process with microsecond time fidelity and submillimeter resolution, while generating petabytes of data.

Such an unprecedented amount of information, combined with proprietary web-based analysis tools, can help shorten the path between simulation and engineering insight. During a typical two-year development cycle, software users can iterate on a design up to 10 times faster to accelerate learning and improve the design.

Microturbine supply expands in shales

Capstone Turbine Corp. has received an order for 25 C65 microturbines to fulfill the continual expansion of existing oil and gas customer fleets in shale plays across the western US.

Horizon Power Systems secured the order, which is expected to be commissioned later this year.

The natural-gas-fueled C65 microturbines will be installed in dual mode, which allows each customer to operate independently of the grid or with the grid in a load-sharing capacity. Once commissioned, the microturbine systems will decrease the operating costs of key US shale operations and ensure that reliable power is delivered to each site.

Fuel conditioning systems for vessels

Alfa Laval has won its first order for a new, compact heat exchanger for gas fuel conditioning from the Korean shipbuilder Daewoo Shipbuilding and Marine Engineering (DSME). The order has an approximate value of $3 MM. Deliveries have already started and are expected to be completed in 2016.

The compact Alfa Laval heat exchanger, a new addition to the marine portfolio for alternative fuels, can reportedly handle temperatures and pressures greater than other welded-plate heat exchangers.

In this case, they will have a dual functionality since they will be installed onboard six LNG carriers to be built by DSME. There, they will reliquefy the boiloff gas from the tanks and simultaneously condition the engine’s fuel gas.

Additional progress for Rio Grande LNG

Valinor Management LP and Halcyon Energy Investors LP have joined certain funds managed by York Capital Management Global Advisors LLC and its affiliates in providing NextDecade LLC with an additional $85 MM to take the Rio Grande LNG (RGLNG) and Rio Bravo Pipeline project to a final investment decision (FID), as well as to fund the continued development of Pelican Island LNG (PILNG) in Galveston, Texas.

The terms of the transaction include options for NextDecade’s three strategic investors to invest the requisite FID equity sufficient to commence the RGLNG project’s construction. Together, York, Valinor and Halcyon manage assets in excess of $40 B. Jefferies LLC served as sole placement agent for NextDecade.

Since entering the US Federal Energy Regulatory Commission (FERC) pre-filing process in March, RGLNG has made strides in engineering and design, regulatory commitments, LNG marketing and local community outreach. As previously announced, NextDecade executed a front-end engineering and design (FEED) agreement with CB&I, along with the terms under which CB&I could assume the role as the RGLNG project’s engineering, procurement and construction (EPC) contractor.

NextDecade also submitted Draft Resource Reports 1 and 10 to the US FERC in May, and successfully engaged local communities through open houses in Kingsville, Raymondville and Brownsville (Texas) regarding plans for the RGLNG and Rio Bravo Pipeline projects.

NextDecade plans to complete FEED by the end of the year and enter the full National Environmental Policy Act (NEPA) filing process with the US FERC in 1Q 2016. NextDecade expects RGLNG to achieve first LNG by 3Q 2020.

New filtration and separation subsidiary

Nexo Solutions LLC has formed a new subsidiary, Amine Filtration Co., specializing in technology and engineering, with expertise in filtration and separation and an extensive knowledge of amine units in particular.

Using state-of-the-art filtration and coalescing technology, technical services and troubleshooting, the new subsidiary will focus on the contaminant aspects of amine units.

All Amine Filtration Co. systems are custom-designed for their specific application, including individual feedstream composition and amine solvent type. The company operates independently of Nexo Solutions, and it provides technologies such as inlet feedgas filtration and coalescing systems, rich-amine filtration and coalescing systems, lean-amine filtration systems, activated-carbon adsorption-bed systems, amine carryover recovery systems, and amine foaming control systems.

South Louisiana gas activities buck the trend

As drilling activity continues to slow in many North American shale plays, South Louisiana’s conventional deep gas resources are providing rich gas reserves growth opportunities. Macro industry trends indicate that shale gas drilling activity will continue its pullback in the near term, although this does not seem to be affecting Louisiana’s independent deep gas drillers.

The addition of large rich gas reserves for each successful well completion has spurred activity over the past few years; this trend is expected to continue. PSI Midstream’s midstream

assets sit at the center of the rich gas resource play in Louisiana’s Vermilion Parish, providing producers with midstream infrastructure, including a recently expanded gathering system and cryogenic gas processing plant, the Kaplan plant. In addition, PSI owns the Cameron Meadows gas plant west of Vermilion Parish in the adjacent Cameron Parish.

The expansion of PSI’s Kaplan gas processing facility provides PSI’s producers with access to a second cryogenic NGL recovery train and two additional gas-turbine-driven compressors, allowing the plant to process up to 225 MMscfd. The plant’s cryogenic processing capacity can be further expanded to 300 MMscfd with additional compression, as demand dictates. Kaplan’s present processed gas volumes are 170 MMscfd. An estimated incremental 30 MMscfd sourced from the PetroQuest-operated Thunder Bayou Prospect discovery well was expected in May.

It is anticipated that gas plant volume throughput will continue to increase with the exploitation of additional deep gas prospects located both onshore and in coastal shallow waters by other active producers in the area.

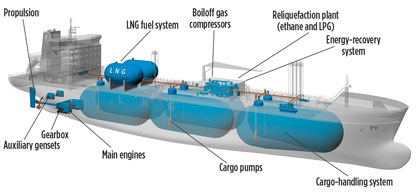

Vessel features advanced engine systems

|

The first in a series of 27,500-m3 Dragon-class vessels ordered by Evergas has been delivered from the Sinopacific Offshore & Engineering (SOE) shipyard in China. The vessel’s comprehensive Wärtsilä solutions package includes two 50DF dual-fuel engines, propulsion equipment including the gearbox, two 20DF auxiliary generating sets, an LNG fuel system and a cargo-handling system. The various systems are fully integrated to achieve maximum efficiencies. The order was placed at the beginning of 2013.

The various integrated solutions form an optimized package. In addition, by engineering and supplying the complete cargo plant, the gas fuel supply system and the propulsion plant enable Wärtsilä to achieve optimal energy consumption efficiency for the entire vessel. For example, the LNG supply system is integrated with the cargo-handling system so that it can be used to cool the cargo.

INEOS Europe is chartering the vessels to transport ethane to Europe from the Mariner East project in the US. In addition to ethane, the purpose-built carriers can also transport a range of petrochemical gases, LPG and LNG. The Dragon-class vessels are 180 m long and 26.6 m wide, with a draft of approximately 9 m. They are said to represent the largest ethane carriers of their class in the world.

Second Methanex plant relocated to Louisiana

|

Mammoet has successfully completed the final phase of the Methanex Geismar 2 plant relocation from Punta Arenas, Chile to Geismar, Louisiana, US. Jacobs Engineering Group Inc. subcontracted Mammoet to support the reverse modularization of the plant and to assist in the heavy lifts, heavy haul and transport of the methanol plant over a 5,450-mi distance.

Methanex decided to relocate a second plant from Chile to Louisiana in 2013. Compared to a newbuild, relocation offers capital savings and a reduced project time frame. Mammoet supported Jacobs with the modularization of the originally stickbuilt facility to ensure compatibility with Mammoet’s equipment and to prepare the modules so that they would withstand the harsh environment during transport.

This second unit and its many heavy components had a combined weight of 183,556 t. During the course of the project, Mammoet lifted over 350 heavy components and modules and set them up for reassembly. The company also managed subcontractors, secured permits and maintained full oversight over the transport operation, which included chartering of all ships for the project through Mammoet’s own chartering office. All of the cargo was brought safely into Geismar, Louisiana.

Port Arthur NGL facility under discussion

Sempra LNG has executed a non-binding memorandum of understanding (MOU) with

an affiliate of Woodside Petroleum Ltd. to discuss and assess the potential development of Sempra LNG’s proposed Port Arthur liquefaction project in Port Arthur, Texas.

The MOU is the first step in exploring this opportunity and undertaking due diligence for the project’s potential development. Any decision to proceed with a binding agreement between Woodside and Sempra LNG in relation to the potential project development, including the establishment of any JV or partnership between Sempra LNG and Woodside, is contingent upon the completion of project assessments and necessary internal and external approvals

for each party.

The proposed Port Arthur liquefaction project would be located at a site previously permitted for an LNG regasification terminal, and would be designed to include two NGL trains with a total export capability of approximately 1.4 Bcfd, as well as LNG storage tanks and marine facilities for LNG ship berthing and loading.

In March, Sempra LNG’s affiliate, Port Arthur LNG LLC, initiated the US Federal Energy Regulatory Commission prefiling review for the proposed NGL facility and filed its permit application with the US Department of Energy.

JV contractor picked for Mozambique LNG

CCS JV, the JV company of Chiyoda Corp., CB&I and Saipem, has been selected as contractor for the initial development of the onshore LNG park in Mozambique, Africa, by Anadarko Petroleum Corp. on behalf of the co-venturers in Mozambique’s Offshore Area 1. The selection of CCS JV is subject to negotiation and entry into a definitive agreement prior to Anadarko and its co-venturers taking a final investment decision.

Initial work for the onshore LNG park includes two LNG trains, each with a capacity of 6 MMtpy, two LNG storage tanks, condensate storage, a multi-berth marine jetty, and associated utilities and infrastructure.

CCS JV has a long-term relationship with Anadarko and its partners for the project’s planning and development and will bring the three companies’ experience in LNG to successfully complete the LNG project.

Comments