Gas processing news

INEOS dives into UK shale gas industry

Swiss chemicals firm INEOS is planning to invest $1 B in UK onshore shale gas exploration and appraisal. Further investment would follow if the company moves into development

and production.

If INEOS wins all of the petroleum exploration and development licenses (PEDLs) it has bid for from the UK Department of Energy and Climate Change (DECC), then the company will become the biggest player in the UK shale gas industry.

The vast majority of the INEOS bids are in Scotland and the north of England, where the local populations have either a mining or an industrial heritage. The company believes that an indigenous shale gas industry would transform UK manufacturing and that the gas can be extracted safely and responsibly.

INEOS already owns two substantial shale licenses in Scotland comprising over 120,000 acres, in addition to investing a further £400 MM in an ambitious project to bring US shale gas to Grangemouth, Scotland.

The company has also announced plans to give local communities 6% of the revenues from any shale gas it produces (with 4% going to homeowners and landowners above the well and 2% going to the wider local community). This offer is typically worth £375 MM to a community, and evidence is starting to suggest that many communities welcome it.

Applied LNG begins building Texas LNG project

Construction has started on the first liquefaction train of Applied LNG’s Midlothian, Texas LNG plant. Applied LNG recently closed a $22.5-MM senior secured loan to complete the funding

of the project.

The plant’s first liquefaction train is expected to be completed in mid-2015. It will be the company’s third liquefier, along with the two operating in Topock, Arizona, and it will increase Applied LNG’s production capacity to 258 Mgpd of LNG.

Microturbine orders climbing for US shale

|

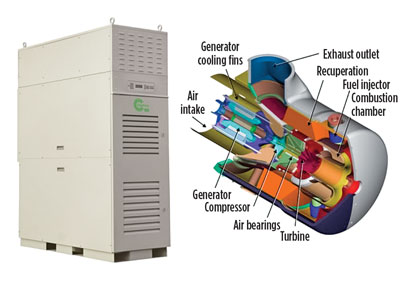

Capstone Turbine Corp. has received an order for 15 C65 microturbines for shale oil and gas customers in the US. Horizon Power Systems, Capstone’s exclusive oil and gas distributor for the Eagle Ford, Permian, Barnett, Mancos, San Juan and Wattenberg shale plays, secured the order.

The turbines will serve various facets of the shale oil and gas production process, including the powering of central processing stations, metering stations, wellhead operations and flare reduction.

With oil, gas and other natural resources serving as Capstone’s largest market segment, shale plays have become a major focus in 2015. The ultra-low-emission, low-maintenance microturbines are said to operate more efficiently and for longer periods of time than typical reciprocating engine generators.

The microturbines can be used in all phases of oil and gas production, including upstream, midstream and downstream operations in both onshore and offshore applications.

Sarita Bay LNG project moves forward

|

Huu-ay-aht First Nations and Steelhead LNG have signed a contract with WorleyParsons, which could be worth in excess of $30 MM, for environmental, engineering, geotechnical and regulatory services at their proposed LNG project at Sarita Bay on Vancouver Island, Canada.

The project, a 24-MMtpy land-based facility, is one of the largest proposed LNG projects in British Columbia. The new contract will encompass environmental impact assessments, pre-FEED studies, geotechnical investigations, and permitting approvals support for the project.

WorleyParsons’ environmental team will be supported by Hemmera, a Canadian environmental consultancy, creating a team of leaders in environmental and social sciences with expertise in environmental assessment, marine and terrestrial ecology, and experience working

with First Nations.

The new contract is an extension of the strategic relationship that already exists between WorleyParsons, Steelhead LNG and Huu-ay-aht First Nations. WorleyParsons played a key role in the preliminary assessment and screening stage of the proposed project, which is

now complete.

If a final investment decision to build the proposed LNG facility is made in 2018, it is expected that up to 4,000 jobs would be filled during the construction phase, with 300 to 400 full-time jobs created once the plant is operational.

Gas plant commissioned in Niobrara shale play

Williams Partners and Crestwood Midstream Partners have commissioned the Bucking Horse gas processing facility located in Converse County, Wyoming, adding 120 MMcfd of processing capacity in the Niobrara shale play.

The Bucking Horse plant, along with the Jackalope Gas Gathering System (JGGS), is owned by an equal JV of Williams Partners and Crestwood Midstream Partners.

The gathering and processing facilities provide services under a long-term, fee-based agreement with Chesapeake Energy Corp. The JGGS includes approximately 184 mi of low-pressure gathering pipelines supported by a 311,000-acre area of dedication from Chesapeake.

The JV expects volumes through the Bucking Horse plant to ramp up throughout the remainder of the first quarter of 2015.

Compression program offers tech access

GE’s Distributed Power business has launched the Gas Compression Power Packager program, designed to provide customers in gas compression applications with enhanced access to Waukesha parts and skilled service technicians.

The program increases the opportunity for end users to access Waukesha gas engine technicians in growing oil and gas spaces around the world through increased factory training to participating packaging companies.

End users can also benefit from lower engine lifecycle costs through increased access to Waukesha parts. At the Platinum level, the program permits qualified gas compression packagers to purchase genuine Waukesha parts and services directly from GE.

The global gas compression packaging company Enerflex Ltd., headquartered in Calgary, has signed on to become the first participant in the Gas Compression Power Packager Program. Enerflex has transitioned its Waukesha distributor relationship in four regions (Canada, the northern US, Australia and Indonesia) to the new Power Packager Program.

Enerflex will continue to serve as the authorized distributor and service provider for GE’s Jenbacher gas engines in Canada, under its Gas Drive Global brand.

First gas reaches Curtis Island

|

Australia Pacific LNG has reached a significant milestone with the arrival of first gas from its coal seam gas fields in the Surat basin to its LNG facility on Curtis Island offshore Queensland, Australia.

The arrival of the first gas into the LNG facility also marks the completion of the commissioning of the 530-km high-pressure gas pipeline, another important project milestone.

With the pipeline completion and the arrival of the gas, Australia Pacific LNG can initiate the commissioning of the island’s power generation facilities.

The LNG facility’s commissioning phase also includes verification and testing of each system of the first processing train and the two LNG tanks.

Australia Pacific LNG Pty Ltd. is an incorporated JV between Origin Energy Ltd. (37.5%), ConocoPhillips (37.5%) and Sinopec (25%).

AFW to engineer synGTL project

Amec Foster Wheeler (AFW) has signed an agreement with D’Arcinoff Group, a US-based investment and alternative technology development company, to provide engineering and technical services for an integrated, 30-Mbpd syngas-to-liquids (synGTL) facility being

built in Texas.

The project, known as the West Texas Renewable and Gas Monetization Project in Hudspeth County, Texas, is part of the D’Arcinoff Group Energy Program, an environmentally conscious GTL and biomass-to-liquids and power generation initiative.

AFW’s scope of work includes engineering design and definition work using key process technology and equipment suppliers, as well as execution planning activities for the facility. The synGTL project will use biomass gasification to process West Texas shale gas in a Fischer-Tropsch unit for the production of jet fuel.

China completes shale LNG plant

Jereh has successfully completed the construction of China’s first shale gas liquefaction plant in Sichuan, China, with a capacity of 2.47 MMcfd of LNG.

The plant is located in Junlian County. In 2014, shale gas output in Junlian was 3.53 MMcfd, while local demand was 423.8 Mcfd.

Jereh’s project will start in January 2015, with a capacity of up to 10.6 MMcfd.

MHI gets LNG carrier order for shale gas

Mitsubishi Heavy Industries (MHI) received an order for two next-generation LNG carriers from Mitsui & Co. The event marks the first order placed to MHI for LNG carriers to transport shale gas.

The carriers will feature improved LNG carrying capacity and fuel performance through a more efficient hull structure and an innovative hybrid propulsion system. The Steam Turbine and Gas Engines (STaGE) propulsion system combines a steam turbine and engines that can be fired by gas.

The STaGE system comprises the ultra-steam turbine (UST) plant, an efficient reheating steam-type marine turbine developed independently by MHI, a dual-fuel diesel engine capable of operating on gas and oil and an electric propulsion motor.

The vessels will be put into service in the US for Cameron LNG Project 1, an initiative in which Mitsui is participating. The vessels will be constructed at MHI’s Nagasaki Shipyard & Machinery Works and are scheduled for completion and delivery in 2018 and 2019.

UK to spend £31 MM on subsurface research

The UK government is allocating £31 MM of funding to develop two subsurface research test centers through the British Geological Survey (BGS) of the Natural Environment Research Council (NERC). The effort will establish a knowledge base that will be applicable to a wide range of energy technologies, including shale gas and carbon capture and storage.

The project was announced at the Thornton Science Park, part of the University of Chester, where the first site is expected to be located. The location of the second site is still to be determined.

This system provides an opportunity to improve the understanding of the UK’s underground environment and will ensure that it is closely monitored. It will also provide independent scientific evidence to the government to help it determine future energy policy.

The results of this monitoring study will be made freely available to the public. NERC is working to establish the project board, which will develop a full scientific case and a stakeholder engagement plan.

FLNG vessel contract awarded to ABB

|

ABB won a contract worth more than $50 MM to supply the electrical system for one of the world’s first commercial floating LNG (FLNG) facilities, and the second to be owned by Petronas. It will be called PFLNG2.

The contract was awarded in the fourth quarter of 2014 by Japanese engineering contractor JGC Corp. JGC is part of a consortium that is building the facility for Petronas, along with Samsung Heavy Industries (SHI) of South Korea.

Under the terms of the contract, ABB will support the optimization of the facility’s electrical side by designing, manufacturing and supplying transformers, switchboards, motor-control centers and a power management system. In addition, ABB will manage the equipment installation and ensure that the electrical supply is integrated with the systems it is powering.

PFLNG2 will be built at SHI’s yard in Geoje, South Korea in 2015. When operations start in 2018, the facility will be moored over the deepwater Rotan gas field located off the Malaysian coast. The vessel is designed to produce 1.5 MMtpy of LNG for at least 20 years before it requires a dry dock.

The machinery and controls supplied by ABB for PFLNG2 will be accommodated in two electrical houses, or e-houses, that rise as high as a five-story building. These prefabricated steel substations designed by ABB ensure that the equipment remains safe from the corrosive marine environment and hazardous gas, and that they provide a safe environment

for the operations crew.

NGL pipeline expansion moves forward

Enterprise Products Partners LP announced that shipper commitments received during a binding commitment period will support its proposed expansion of Panola Pipeline Co. LLC’s NGL system.

The 181-mi system originates near Carthage, Texas and extends to Mont Belvieu, Texas, where it serves multiple destination points, including facilities owned and operated by Enterprise.

As part of the expansion project, Enterprise plans to install 60 mi of new pipeline, along with pumps and other equipment designed to increase system capacity by 50 Mbpd. The incremental capacity is expected to be available in the first quarter of 2016.

Mid-sized LNG project for Louisiana

Louisiana Governor Bobby Jindal and Martin Houston, chairman of Live Oak LNG, announced that a new natural gas liquefaction and export project, worth up to $2 B, will be developed in the Calcasieu waterway of Louisiana.

The mid-sized project is being designed for a plant capacity of up to 5 MMtpy and will include two 130,000-m3 storage tanks and port facilities with a jetty for standard-size LNG carriers.

The proposed site is about 350 acres and is situated within Calcasieu Parish on the west bank of the Calcasieu River.

Initial study work is already underway, and Live Oak LNG (a fully owned subsidiary of Parallax Energy) has initiated the permitting process.

Live Oak LNG has awarded Bechtel a contract for the pre-engineering design, and Chart Industries has been selected for the process design work.

The plant is anticipated to start up in late 2019.

Fluor lands US gas transmission project

Fluor Corp. has been awarded a contract by NEXUS Gas Transmission to provide EPCM services for an approximately 250-mi natural gas transmission pipeline in Ohio and Michigan that will be capable of transporting 2 Bcfd. The main line will have a diameter of 42 in.

In addition to the main line, Fluor is designing and managing the construction of up to four compressor stations in Ohio to maintain the pressure needed to push the gas through the pipeline, as well as four meter stations that will provide flow control and gas quality monitoring services.

DTE Energy Co. and Spectra Energy Partners LP are the lead developers of the NEXUS project, which is expected to cost approximately $2 B and is designed to deliver incremental production from the Utica and Marcellus shale plays to meet growing gas demand from distribution and end-use markets in the upper Midwest and in Canada.

Dual-fuel engines to power LNG vessel

|

A specialized LNG bunker vessel to be built at the STX Offshore & Shipbuilding Co. yard in South Korea for Shell will be powered by Wärtsilä dual-fuel engines. The ship will be used to deliver gas to LNG-fueled vessels in northwest Europe. The engine order was placed with Wärtsilä in December 2014.

The new Shell vessel will be based at the port of Rotterdam in the Netherlands, and will load from the new break bulk terminal and jetty to be constructed by the Gas Access to Europe (GATE) terminal. It will also be seagoing and able to bunker customers at other locations. The vessel will be powered by three eight-cylinder Wärtsilä 20DF dual-fuel engines capable of operating on either gas or diesel. The engines are scheduled for delivery in spring 2016.

Wärtsilä’s dual-fuel technology enables engines to be operated on either natural gas, light fuel oil or heavy fuel oil, and switching between fuels can take place seamlessly during operation, without loss of power or speed, ensuring safety and continuous installation operability. Wärtsilä dual-fuel engines are designed to have the same output regardless of the fuel used.

Partnership to develop GTL facilities

Greyrock Energy has formed a partnership with Nerd Gas Co. LLC to develop GTL facilities in the US.

Founded by Mick McMurry in 1996, Nerd Gas is a private Wyoming-based energy investment company with a focus on the efficient and responsible exploration of hydrocarbons in Wyoming and the northern Rocky Mountains region.

Nerd Gas has invested in the previously announced Sterling Greyrock GTL project to confirm the commercial viability of small-scale GTL. Through an affiliate, US GTL, Nerd Gas and Greyrock are partnering to explore the feasibility of GTL plants in Wyoming and other locations.

The Nerd Gas and US GTL teams have expertise in hydrocarbon technologies, including GTL.

Greyrock’s facilities produce premium synthetic diesel fuel from natural gas or NGL, using the company’s GreyCat catalyst and distributed GTL (dGTL) solution. Modular gas conversion can be achieved from a variety of sources, including natural gas, NGL (such as ethane), stranded gas resources and associated gas.

Membrane tank added to standard for LNG storage

The new release of the Canadian standard for LNG production, storage and handling now includes and recognizes GTT’s membrane tank system as a possible technology for land storage of LNG in Canada.

The membrane containment system technology has been integrated into the newly published 2015 Canadian standard CSA Z276. This request was originally initiated by the LNG community to meet the challenges of LNG export projects in remote locations.

Inclusion of the membrane containment tank language took more than two years and underwent a rigorous certification process, including public review. It has been realized in collaboration with world LNG tank and LNG facility safety experts from major EPC companies and oil and gas majors.

The language takes into account the latest international tank design standards, such as API 625, API 620 and ACI 376, as well as EN 14620.

The new edition of CSA Z276 follows the action of the British Columbia Oil and Gas Commission (BCOGC), which officially included membrane tank technology in its LNG regulation issued on July 21, 2014.

With the new edition of the CSA Z276 standard, the membrane tank technology is addressed in British Columbia as well as in other Canadian provinces.

Study finds low gas plant methane emissions

The vast majority of natural gas collection and processing facilities have methane leak rates of less than 1%, according to a major field study led by Colorado State University that examined 114 gathering facilities and 16 processing plants across 13 states.

According to the study, 101 out of the 130 facilities examined had methane loss rates of below 1%.

Methane emissions from oil and gas production declined by 38% between 2005 and 2012, and methane emissions from hydraulically fractured natural gas wells have plummeted by 73% since 2011, according to US Environmental Protection Agency (EPA) data.

A major field study conducted in 2014 by the University of Texas and sponsored by the Environmental Defense Fund and natural gas producers found that methane emissions from the development and production of natural gas are down 10% from what the same research team found a year earlier. These emissions now represent only 0.38% of production.

“The US EPA’s own analysis shows that new methane regulations announced by the Obama administration are unnecessary in view of the dramatic progress the oil and natural gas industry is already making in reducing emissions,” said Howard Feldman, the API’s senior director of regulatory and scientific affairs.

Encana licenses gas dehydration technology

PROSERNAT will provide its technology licenses for eight of Encana Corp.’s new Ifpexol units to be located in British Columbia, Canada. This contract is part of the Encana Cutbank Ridge development program.

The eight Ifpexol units, with a total processing capacity of 1,600 MMscfd of feed gas, are being designed for gas dehydration and hydrocarbon dewpoint control. The Encana units will mark the first application of PROSERNAT’s technology for shale gases.

The technology was originally developed by IFP Energies nouvelles and is used in both onshore and offshore projects for simultaneous water and hydrocarbon dewpointing of natural gases.

Demo biogas plant opens in Sweden

GoBiGas, the world’s first large-scale demonstration plant for producing biogas through the gasification of biofuels and residues from forestry, is now operating and supplying gas to the Swedish natural gas grid.

Haldor Topsøe provided the licensing, catalyst and engineering for the gas cleaning, as well as for the methanation section of the project, enabling the plant to produce substitute natural gas (SNG) by thermal gasification of forest residues. The biomass is converted to gas with a methane content of over 95%, and the plant has a capacity of 20 MW of SNG.

The GoBiGas project consists of two primary phases. Phase 1 established the demonstration plant now in operation, and Phase 2 will expand to a full-scale commercial plant with a capacity of 80 MW of SNG.

Haldor Topsøe claims to be the only licensor in the world with proven biomass-to-SNG technology.

NY gets mobile CNG refueling station

The Virtual Pipeline system, a solution created by Galileo Technologies to transport natural gas by road where there are no pipelines, will be used as a mobile CNG station. It is said to be the first such operation in the US, where CNG is becoming a matter of interest as an alternative to traditional liquid transport fuels.

Mobile Fuel Solutions (MFS), a New York company specializing in the supply of fuel, is preparing to set up the first of two Virtual Pipeline systems to fuel two large fleets: one that transports goods and the other offering public services, both at refueling places and on the road.

The operation will allow a number of companies to utilize CNG fuel without the need to invest in their own fuel stations, which are expensive and difficult to permit. It will also shorten the distance between the small network of CNG stations in New York and consumers, as it will no longer be necessary to move vehicles away from their routes to refuel.

The mobile platform of the Virtual Pipeline system uses a VST-2 trailer, equipped with two modular containers. The first one transports 28 horizontal cylinders of CNG and 297 gal of gasoline equivalent (GGE), and the second one transports 39 cylinders and 418 GGE.

The system’s advantage relies on the first container with lower capacity, as this “B-type” modular container houses the hydraulic compressor and the pump that allow the trailer to run as a mobile station with a fuel stock of CNG higher than 700 GGE. GP

Comments