What’s new in gas processing technology

H. Meche, Associate Editor

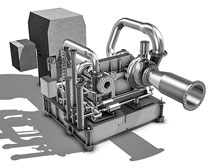

Residue compressor aids NGL recovery

The Atlas Copco TP Series residue gas compressor incorporates a three- to four-stage, dual-pinion integral gear design that delivers high flow levels and superior performance for NGL recovery plants. A single TP Series compressor unit can often replace multiple reciprocating compressors, and it can fully cover plants up to a rated flow of 120 MMscfd. Driven by an electric motor, it is a lower-emission alternative to engine- or turbine-driven compressors.

The compressor’s integral gear technology operates two pinions through a common bull gear. This integral gearing allows for a more compact design and multi-speed capability for optimal speed at each stage. Meanwhile, the horizontally split gearbox provides easy access to bearings, gearing and oil seals for simple maintenance.

The impellers can be replaced onsite. They are designed using the latest computational fluid dynamic and finite element analysis. Variable inlet guide vanes determine how much gas flow is sent to the impellers, and they ensure an optimum flow angle at the leading edge of the impeller blade.

The compressor is delivered on a compact skid that includes the compressor unit, the lube oil reservoir, the lube oil system and the compressor support assembly. The motor drive support is typically supplied by the customer. The compressor can easily accommodate electric drive motors, and it can likewise be mounted to gas-fed engines to take advantage of the plant’s excess gas streams.

Other TP Series compressor features include a high-speed pinion seal system that uses single dry-face seals; hydrodynamic, horizontally split bearings and oil seals; standardized packaging; optional interstage coolers and monitoring systems; and adherence to American Petroleum Institute specifications.

IR device monitors 100 gases

The Chemgard photoacoustic infrared (IR) gas monitor provides precise, low-cost monitoring for 100 different industrial gases, including 59 standard gases.

The gas monitor’s photoacoustic IR technology ensures extreme stability and operation for months with virtually no zero drift, making it highly selective to the gas of interest. A gas sample is taken into the monitor’s measurement chamber and exposed to a specific IR light wavelength. If the sample contains the gas of interest, then that sample will absorb an amount of IR light proportional to the sample’s gas.

A highly sensitive microphone detects the audible pulse of moving gas particles. No downtime occurs, no fresh air sampling lines are needed, and users have lower detection levels, down to 1 ppm, for faster response.

The three different enclosure styles include the NEMA 4 version, a rack-mount version and an explosion-proof version.

Economical nitrogen tank blanketing

The ST100 Series flowmeter from Fluid Components International (FCI) is designed for mass flow measurement of nitrogen (N) gas in tank blanketing processes. A range of choices is available to accommodate various tank and line sizes.

Accurately measuring the blanketing gas is important because adding too much gas is unsafe, wasteful and expensive. Installing an ST Series flowmeter upstream of a tank’s regulator valve allows N flowrate monitoring and control.

FCI’s mass flowmeters are calibrated to specific gases, such as N, in FCI’s NIST-approved calibration laboratory. Up to five calibration groups can be stored to support a broad flow range, differing/same gas mixtures and multiple gases, with a flow range in excess of 100:1.

The flowmeter features thermal dispersion mass flow sensors and rugged packaging. The thermal flow sensing element measures flow from 0.25 sfps to 1,000 sfps, with accuracy of ±0.75% of reading and ±0.5% of full scale. Communication options include a 4-20 mA analog, frequency/pulse or certified digital bus communications. The graphical, multi-variable, backlit LCD display provides local information with a continuous display of all process measurements and alarm status, as well as service diagnostics.

Designed for use in rugged industrial applications, the ST100 flowmeter operates at up to 850°F and is available with both integral and remote (up to 1,000 ft) electronic versions. The instrument is agency approved for hazardous environments.

Analyzer accurate in changing gas streams

Michell Instruments’ OptiPEAK TDL600 analyzer for natural gas uses tuneable diode laser spectroscopy (TDLAS) technology, offering accuracy with a lower detection limit (LDL) of less than 1 ppmv.

Since TDLAS moisture analyzers measure the reaction of molecules to specific frequencies of light, changes in the background composition of the gas require the analyzer to be adjusted to maintain its accuracy. Michell’s scientists developed the dynamic methane compensation system (D-MET) to overcome this problem. With D-MET, the OptiPEAK TDL600 analyzer can measure moisture in natural gas with varying compositions.

The analyzer has an accuracy of ±1%, and its laser lock system automatically monitors the optical profile of the gas absorption peaks to ensure that the laser remains locked to the correct water absorption signal. The analyzer’s optical measurement technology is non-contact, and measurements can be made immediately.

Additionally, none of the sensing components are subjected to the gas stream, protecting them from aggressive compounds and contamination.

Air filter system cuts corrosion

The ODSY vCell air filtration system from CLARCOR provides turbine protection against the environmental challenges of remote locations with unique hydrophobic properties and high-efficiency performance. Field trials show reductions in gas turbine output degradation between filter washes, leading to increased output. Trials in high-moisture, high-salt coastal sites also show negligible corrosion of turbine blades after 20,000 fired hours.

The air filtration system has a filtration efficiency grade of E12 per EN1822:2009, which is equal to a minimum 99.5% of most penetrating particle size (MPPS). Its extended filtration surface area ensures low pressure loss and supports extended filter life. Clean pressure loss at the rated flow of 5,300 m3/h is just 260 Pa, and salt-removal performance is 99.9999974%.

Valve actuator for remote shutdown

Emerson Process Management’s Bettis electro-hydraulic operator (EHO) actuator is designed for a diverse range of applications, from topsides valve automation on offshore platforms to remote pipelines where operational upsets can cause safety and environmental hazards, as well as costly production losses.

To help operators counteract these challenges, the EHO provides a compact design with actuator and control components from Emerson. It is available in either spring-return or double-acting configurations. Torque outputs can handle valve sizes from 6 in. to 60 in.

The actuator can operate in temperatures ranging from –40°F to +140°F. Its failsafe capability is reliable, with fast-close or open-stroke times, making it suitable for emergency shutdown in oil or gas service.

www.emersonprocess.com/BettisEHO

Globe valves get firesafe approval

Bestobell Marine has secured approval for its new DN350 and DN400 cryogenic globe valve designs. Developed specifically for the marine sector, the valves have been fully tested and certified for installation on LNG carriers.

The fire test procedure exposes valve components to temperatures over 1,000°C and requires the valves to demonstrate that they will not leak gas to the atmosphere and through the valve seat. This standard can only be achieved by designing the valve to proven firesafe standards, with an all-metal seat construction and graphite gaskets and packings that are not affected by high temperatures.

It is essential for LNG carrier safety that cryogenic valves are completely firesafe, as any leakage of gas from a valve in the event of a fire could lead to a catastrophic explosion onboard.

Valve range offered in duplex materials

Wärtsilä Shipham Valves has extended its full range of duplex and super-duplex stainless steel valves to cover higher pressure ratings. The product range of gate, globe, check, ball and butterfly valves can now be specified in duplex and super-duplex, with sizes ranging from 0.5 in. to 48 in., and pressure ratings up to American National Standards Institute (ANSI) 1,500 lb.

Wärtsilä’s expanded duplex and super-duplex valves now handle a broader scope of applications requiring enhanced resistance to corrosion and erosion. The duplex and super-duplex valves meet the requirements of Norsk Sokkels Konkuranseposisjon (NORSOK) M630, D46 and D56 material specifications.

Comments