What’s new in gas processing technology

H. Meche, Associate Editor

Detectors protect portable LNG vaporizers

To protect natural gas production sites, General Monitors offers a complete line of fixed hydrocarbon gas and flame detectors. The company’s advanced catalytic-bead, infrared point and ultraviolet/infrared (UV/IR) technologies provide hydrocarbon hazard monitoring

in rugged environments.

The S4000CH combustible gas detector continuously monitors combustible gases via its robust catalytic-bead technology. It features one-person calibration and can virtually self-calibrate through the activation of a magnetic switch and the application of gas. The unit monitors natural gas and vapors within the lower explosive limit (LEL) and provides status indication and alarm outputs. It complies with ANSI/ISA 12.13.01-2000 performance requirements for combustible gas detectors.

The IR400 Point IR gas detector uses IR technology to sense for combustible gases and vapors to quickly detect LNG gas leaks. The detector comes factory pre-calibrated, has a three-second response time, operates with less than 4.8 W of power, and is inexpensive to operate and maintain.

The FL3100H UV/IR flame detector monitors for UV and IR spectral ranges and is immune to false alarms caused by radiation sources. Continuous optical path monitoring (COPM) checks both optical path integrity and electronic circuitry once per minute. The detector’s electronics are integral within its explosion-proof housing, allowing the processing of detector information at the point of detection.

System remotely monitors compressors

The SAT110 portable remote terminal unit (RTU)/alarm dialer features a built-in battery, a vibration sensor, input/output (I/O), a magnetic mount and Class 1, Division 2 hazardous-location certification that can be rapidly deployed for monitoring the run/no-run condition of compressors and generators.

The integral GPS allows location tracking of remote assets such as generators, compressors, tanks, skids and buildings. The three integral I/Os allow connection of alarm contacts and switches. The SAT110 can be easily interfaced to the existing supervisory control and data acquisition (SCADA) host, or via smartphone and web browser through the SatSCADA server.

Imaging sensor characterizes gas leaks

Telops’ Hyper-Cam Methane gas detection camera detects, identifies and quantifies small quantities of methane, and even maps methane at concentrations as low as 1 ppm. It adds a specialized, hyperspectral imaging sensor to the Hyper-Cam line of hyperspectral cameras.

The Hyper-Cam Methane camera offers a clear picture of the quantity of methane in a given scene. It is ideal for the characterization of natural gas leaks in hard-to-reach areas; LNG leak detection and quantification; and the detection, identification and quantification of greenhouse gases in environmental research, and other areas.

Structured packings cater to gas treatment

PROSERNAT is commercializing IFP Energies nouvelles’ (IFPEN’s) patented IFPACC-structured packings for gas treatment applications. This move follows IFPEN’s development of a new generation of structured packings adapted to the constraints of acid gas removal by amine solvents. The first product, IFPACC 2X, offers potential debottlenecking or cost savings when included in plant designs.

IFPEN developed a novel structured-packing geometry to manufacture the IFPACC 2X packing elements with a 200-m2/-m3 geometric area. Production and performance tests were performed at near-industrial scale in a 1-m-diameter column. Relative to commercial structured packings tested in the same facility, this new packing offers a higher flow capacity with similar mass-transfer rates.

Process studies performed with measured IFPACC 2X characteristics show that it can provide up to a 17% gain in column throughput after a gas sweetening absorber revamp operation. For new plants, lower investment costs can be attained by reducing column size and weight.

Commercializing the packing will strengthen PROSERNAT’s position in gas sweetening by making it a provider of gas treatment solutions enhanced by using high-intensity internals.

System improves purge solutions for Zone 2 applications

Pepperl+Fuchs’ latest addition to its Bebco EPS line of proven purge solutions is the 5500 series purge and pressurization system. Combined with global certifications, menu-driven programming and automatic leakage/temperature compensation, the 5500 series provides a comprehensive solution for Division 2, Zone 2 applications.

The system comprises three components—a control unit, an enclosure protection vent, and a pneumatic solenoid or manual valve. The interface enables users to select from a list of custom programs to fit specific application needs. Users can also define temperature ranges to control and alarm-critical temperatures within the purge enclosure. When a critical temperature is reached, a solenoid displaces air or initiates heating or cooling functions within the enclosure to keep equipment operating safely and productively.

Additionally, when the control unit detects a drop in pressure,

it automatically compensates to ensure that pressure within the enclosure does not fall below the minimum value. This leakage compensation

helps prevent alarm shutdown and keeps processes up and running.

The EPV-5500 vent works with the 5500 control unit and valve to provide a certified purge and pressurized system for enclosures. It functions as a pressure-relief device, allowing purge gas to exit the enclosure while providing a seal when the enclosure is pressurized and operating.

Transmitter protects assets

Emerson Process Management’s new CSI 9360 vibration/position transmitter offers an economical solution for extending basic protection to compressor, pump and fan assets. The transmitter detects emerging sleeve bearing issues by capturing vibration or position data and translating it into a 4-20 mA signal for monitoring. This advanced warning allows users to shut down the assets before equipment damage occurs or production is impacted.

The CSI 9360 transmitter can be field-configured for three radial vibration ranges or positioned with an invertible position signal, selectable sensor loop response times and optional sensor fault lockout times.

Detector protects against toxic gas

Spectrex Inc.’s 950 and 960 series detectors—the latest additions to its SafEye open-path gas detector range—detect toxic hydrogen sulfide gas and toxic ammonia gas, respectively, both with path lengths of up to 263 ft (80 m).

The Quasar 950 and 960 models can be tailored to protect personnel and high-risk installations. Reliability is ensured with SIL 2 certification (pending). All Quasar 950 and 960 detectors incorporate heated windows to minimize any effects from condensation, icing and snow.

The detectors are also immune to interference from sunlight or any other sources of radiation, such as flare stacks, arc welding or lightning. A range of outputs are available including mA, HART and Modbus RS485, to suit all control systems.

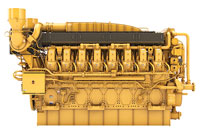

Gas engine offers fuel flexibility

Caterpillar Oil & Gas’ new Cat G3600 engine series offers expanded fuel flexibility, a 5.6% power increase and greater altitude and ambient temperature capabilities.

Additionally, the engines incorporate the advanced ADEM A4 engine control unit, enabling the Cat power solutions to work harder and smarter. Engines included in the new design are the G3606, G3608, G3612 and G3616 models.

Originally introduced to the market in 1984, the Cat G3600 series includes the Cat diesel platform. They offer improved power at both altitude and elevated ambient temperatures, and ambient-based ratings at 43°C and 32°C.

With expanded fuel flexibility, the engines can operate with heavy hydrocarbon-rich fuels, as well as with fuels having high inert gas content.

Gas monitor reliable in extreme conditions

MSA’s SIL 2-certified PrimaX IR combustible gas monitor withstands challenging environmental conditions. With its dual-source redundancy, the PrimaX IR monitor provides uninterrupted monitoring in the event of a source failure.

Obscurations due to environmental conditions are minimized. Maximized optics provide signal and stability. Also, the environmental guard with a patented clamshell design provides convenient installation in tight locations.

Comments