What’s new in gas processing technology

H. Meche, Associate Editor

Pipeline pig indicates inspection readiness

PECAT, a pigging-based inspection tool supplied by Circor Energy-Pipeline Engineering, is helping operators and contractors schedule and plan effective inline inspections (ILI) of pipelines.

Pipeline inspections identify and locate defects and in-service damage that could potentially result in pipeline failure, if not repaired. The inspection operation is performed by “smart” pigs, which vary in technology and complexity, depending on the assessment they will be used to perform.

It is accepted practice for most oil and gas pipelines to undergo ILIs as part of their ongoing integrity management; this may also be a legal requirement. Effective ILI operations rely on pipelines being clean, and operators want to avoid ILI tools being sent through insufficiently cleaned pipelines.

In advance of an ILI, or where pipelines are not regularly cleaned, progressive pigging programs are often carried out to clean the line, with decisions on whether to run an ILI based on the results and debris returns being encountered.

To support and improve the decision process regarding when a pipeline is suitably clean for inspection, the ATEX-certified PECAT tool can be sent through the line. The tool’s built-in patented sensor and data-logging technology measure the debris location and quantity, as well as ovality, temperature and differential pressure. This data helps operators and contractors make informed decisions regarding the readiness of a line for an ILI.

Gas sensors offer extended range

City Technology, a Honeywell company, has added six new sensors to its electrochemical sensor range. The 5OxLL long-life O2 and A5F+ carbon monoxide (CO) sensors extend the 5 Series range, which is used worldwide by high-specification flue gas analyzer manufacturers requiring EN 50379-2 compliance.

The 5OxLL long-life O2 sensor is compliant with the Restriction of Hazardous Substances Directive, and it operates for the entire life of the analyzer. The sensor’s “electrochemical pump” technology removes the need for a consumable lead anode—the life-limiting component in today’s comparable sensors.

The A5F+ CO sensor is ideal for high-range applications (up to 20,000 ppm), which traditionally require a second sensor to meet EN50379-2. The sensor’s robust and advanced design is hydrogen (H2)-compensated, and a high-capacity filter offers reliability

and extends operational life for five years.

City Technology’s new compact 4 Series sensors are designed for use with EN50379-3-compliant analyzers. The range includes the 4OXV O2 sensor, with a two-year life; the 4OxLL long-life O2 sensor, designed to match the average analyzer’s lifetime; and the 4F and 4MF CO sensors, offering low- and high-range measurements: 4F (0 ppm–20,000 ppm) and 4MF (0 ppm–100,000 ppm). Both sensors include internal acid gas filters.

Flowmeter gives measurement stability

KROHNE’s OPTISONIC 7300 universal ultrasonic gas flowmeter is an economic solution for gas flow measurement in process and auxiliary measurements in oil and gas refineries, and in the chemical and petrochemical industry. It also provides benefits to non-custody transfer natural gas applications, as well as (compressed) air, mixed gas, steam or flue gas applications.

The two-beam ultrasonic flowmeter is Class 1, Division 1 approved. It delivers high performance over a wide bidirectional flow range of ±30 m/s (±90 ft/s) with 1% accuracy. As a standard, it uses titanium transducers, which equalize process fluctuations and avoid acoustic feedback. Stainless steel transducers are available on request.

The OPTISONIC 7300 flowmeter is built for long-term use, featuring a maintenance-free, full-bore flow sensor and a sturdy and robust construction with no exposure of cables or sensitive parts. It has no moving parts in the flow sensor, and the wide application range makes using the device cost-effective.

The flowmeter provides calculation to standard conditions by using the input of temperature and pressure sensors that can be directly connected to the device. The electronics also feature diagnostics to validate flowmeter and process functions, and Modbus, FOUNDATION Fieldbus and HART are included for field communication.

Leak detector receives marine approval

Emerson Process Management’s Rosemount Analytical GDU-Incus ultrasonic leak detector has received the Det Norske Veritas (DNV) type approval—a certification further confirming the device’s suitability for use onboard marine vessels, including LNG and LPG carriers, crude oil tankers and FPSO units.

The DNV type approval assures potential users that the GDU-Incus has undergone rigorous testing and has been determined to meet the highest quality standards. The DNV assessment process is built upon scientific research and recognized by regulators, insurers and major clients worldwide.

The GDU-Incus leak detection system’s four acoustic sensors constantly monitor wide areas

for ultrasound generated from the release of pressurized gas. The detector can monitor ventilated outdoor applications and can withstand extreme conditions. Its performance is unaffected by inclement weather, wind direction, leak direction or any potential gas dilution, with an instantaneous response to methane, hydrogen and other low-molecular-weight gases.

The detector’s advanced gas sensing technology does not require calibration or replacement for the instrument’s lifetime. An integrated self-test guarantees failsafe operation, and sensors with no moving parts mitigate maintenance requirements.

LNG pump system passes test

ACD has successfully passed the First Article Test (FAT) for its LNG fuel gas pump system. The MSP-3SLH dual system will fuel TOTE’s Marlin class container ships. The ABS-classified ships will reportedly be the first LNG-powered container ships in the world. They will operate between Jacksonville, Florida and San Juan, Puerto Rico.

The FAT included full performance of the ship’s rated LNG fuel flow requirements, from maneuvering to full-speed conditions. The system achieved 320 bar at flowrates from 1.4 cubic m3/h to 11 m3/h. The American Bureau of Shipping approved the LNG fuel gas pump system.

The US Coast Guard has already approved ACD’s MSP-3SLH design using hydraulic motors for the high-pressure pumps and oil lube system. ACD’s scope also included powering the MSP-SLH dual system with an external hydraulic power unit (HPU), which was also used and approved during the FAT.

The high-pressure LNG fuel supply system features two ACD model MSP-3SLH high-pressure pumps with hydraulic motors and an HPU. Also included is an external oil lubrication system, all integrated on a common skid with piping, high- and low-pressure control valves, and all monitoring equipment.

Cryo cylinder features proprietary design

Worthington Industries Inc.’s US Department of Transportation-approved cryogenic liquid cylinders include proprietary digital and mechanical gauges, and are available with capacities ranging from 180 l net to 265 l net. The cylinders are used to store liquid nitrogen (N), oxygen (O2), argon (Ar) and CO2 for industrial gas markets.

Worthington designed its cryogenic liquid cylinder based on customer insights. Patents are pending on new product features designed to help customers diagnose cylinder performance issues, reducing unnecessary refurbishment costs. A new production area at Worthington’s Westerville, Ohio facility is dedicated to producing the cryogenic liquid cylinders.

Features include the industry’s first liquid cylinder vacuum sensor to diagnose vacuum quality; a proprietary gauge to alert the customer to liquid levels; redesigned customer and distributor interfaces and an optional customized name plate; a center-point lift lug; a raised handling ring for easier valve access; a tamper-proof cap on the pressure-builder regulator adjustment screw; and a bumper guard and mobile base.

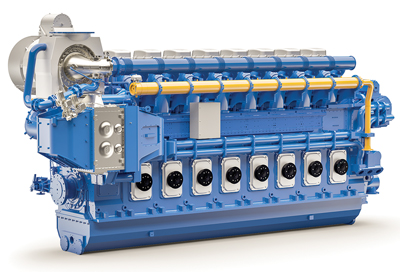

Dual-fuel engines fit for LNG ships, FSRUs

The fuel-flexible Wärtsilä 46DF engine has been specifically developed for LNG carriers, FSRUs, offshore vessels and platforms, and other vessels. It can operate on natural gas, heavy fuel oil or marine diesel oil. This fuel flexibility enables reduced operational expenses, compliance with stringent emissions standards and full redundancy to ensure uninterrupted operation.

The Wärtsilä 46DF consists of two different versions to meet specific needs. The high-efficiency version offers lower fuel consumption with a cylinder power of 1,045 kilowatts (kW), while the high-power version offers a cylinder power of 1,145 kW with excellent engine thermal efficiency. For LNG carrier applications,

the 46DF engine can offer fuel savings of 20 tpd compared to the first introduced dual-fuel engines.

When operating in gas mode, the 46DF engine is already compliant with IMO Tier III regulations, without any secondary exhaust gas purification systems. When fueled by gas, the sulfur oxide (SOx) and carbon dioxide (CO2) emissions are notably reduced, and smokeless operation is attained.

Membrane improves CO2 removal

A research-and-development collaboration between Petronas and Cameron to improve the performance of Cynara carbon dioxide (CO2) membranes, particularly for large offshore CO2-removal projects, has resulted in a patent-pending enhancement, the PN-1 multifiber membrane element. PN-1 improves the Cynara membrane element’s performance by segregating the membrane fiber bundle into two separate zones, each with membrane fibers of different performance characteristics.

Inlet gas flows inward from the outside toward a perforated center core tube, with the highest-concentration CO2 gas making contact with fibers in Zone 1. The CO2 concentration of the inlet gas is reduced (by permeation) as it passes through the layered fiber bundles. The PN-1 membrane configuration allows inner Zone 2 fibers to be optimized to separate the lower concentrations of CO2 in contrast to Zone 1 fibers, resulting in optimized PN-1 membrane element performance.

The first PN-1 variation development has an outer Zone 1 layer with fibers exhibiting high CO2/hydrocarbon separation factors. Subsequently, the inner Zone 2 has fibers that exhibit higher capacity for CO2 removal from lower CO2 gas concentrations. As a result, single PN-1 membrane performance is comparably similar to Cynara two-stage membrane systems operating in series. The single-stage PN-1 technology offers improved equipment size and weight savings, which are critical for offshore operations.

The PN-1 membrane is said to be the largest CO2 separation membrane in the world. It has a proven operational track record in both onshore US (since 2009) and offshore Malaysia (since 2010). In operation, this membrane has shown 8% to 10% higher capacity than standard membranes.

Flow alarm offers unique analysis

Servomex’s SERVOTOUGH FluegasExact 2700 combustion gas analyzer’s measurement sensor capability is augmented by the company’s Flowcube flow sensor technology. Flowcube enables true system diagnostics of the sample flow, ensuring that the measurement is valid.

Placed in line with the measurement sensors, Flowcube allows user-defined alarm levels to be set with confidence, either to enhance preventive maintenance or to act as a flow-failure alarm output. With this technology, operators can implement a preventive, rather than reactive, maintenance agenda for analyzer flow control, allowing the scheduling of routine safety checks and sample system maintenance.

Customer-designed for high-temperature processes up to 1,750°C, the FluegasExact analyzer can be used in extreme heated environments, such as process heaters, utility boilers, thermal crackers, incinerators and furnaces.

Membrane for ethane cargo system

There is a large ethane surplus in the US resulting from increased shale gas production, and interest in ethane, as a product that will require dedicated shipping, is on the rise. The crucial element of selecting containment systems on very large carriers has emerged with orders related to ethane export. Membrane technology is a preferred choice in the LNG shipping market, and it also serves as a viable cargo containment system (CCS) on very large ethane carriers.

GTT has provided designs for sea transport of ethylene and LPG since 1964, with five carriers ranging from 1,100 m3 to 120,000 m3. The hull structure of the GTT CCS provides a competitive advantage in terms of the volume to be transported. The membrane presents a flexible solution that can be adapted to any cargo space available, and the increase in density does not hinder tank adaptation.

Solution improves pipeline measurement

The effects of pulsation on natural gas measurement are a major factor to consider when designing meter installations. Compressors, flow control valves and gas regulators can produce pulsations that influence accuracy. Additionally, some piping configurations can produce vortices that create pulsations. This square root error (SRE) is a positive error that can only be reduced by modifying the piping system.

A secondary effect of SRE is called gauge line error (GLE). This is where the measuring instrument’s differential pressure (DP) at the orifice fitting connection is not the same as the DP at the measurement instrument’s connection. This can be a positive error or a negative error. A study has shown that GLE can be reduced by mounting the instrument closer to the orifice fitting.

Another factor is keeping both sides of the sensing lines from the orifice fitting to the measuring instrument the same length. In gas systems, it is important to install the measurement instrument above the orifice fitting connections to allow self-draining of the manifold and sensing lines.

AS-Schneider’s Schneider DirectMount Systems is a direct vertical assembly, allowing the measurement instrument to be installed within the required distance and with the minimum 9.5-mm orifice diameter from the orifice to the measurement instrument’s sensing element. Large orifice valves also permit self-draining of liquids to prevent liquid build.

At the heart of the Schneider DirectMount Systems is the patent-pending stabilized connector. A special adapter, necessary to connect the valve manifold to the measuring orifice flange, is supported on the flange body to provide more stability. If necessary, AS-Schneider can also equip the connector with an isolation/block valve.

A dielectric isolator kit is installed between the stabilized connector and five-valve manifold, shielding the instrument from electrical voltage and ensuring that there is no metal-to-metal contact between the orifice fitting and the instrument.

Two shutoff valves on the five-valve manifold guarantee a reliable primary shutoff, if the measuring instrument must be dismantled and serviced. The valves are available with different sealing materials and can withstand temperatures from –55°C to 232°C and a pressure up to 420 bar, depending on the version.

New division offers metering, other services

Inspectorate America Corp. has launched the Measurement Services Division, providing North American oil and gas customers with a comprehensive range of meter calibrations, tank calibrations and water-draw services.

Inspectorate, a Bureau Veritas company, is reportedly the first in the market to offer a complete suite of measurement services that can be tailored to fit the scheduled maintenance and operational needs of any producer, pipeline company or storage terminal.

The division’s facilities are located in Lake Arthur, Louisiana; Scott, Louisiana; and Pasadena, Texas. Inspectorate’s network of inspectors and fleet of portable certification equipment ensures that these services can be performed anywhere in North America and internationally.

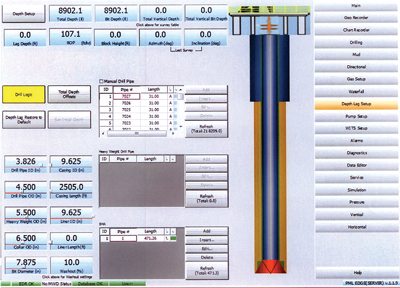

Oil and gas data in the cloud

PML Exploration Services has developed its own gas analysis and rig data-management solutions to provide secure, web-based, real-time information to its customers via the cloud. To enhance safety and increase productivity when drilling natural gas wells, PML analyzes rock cuttings and gases from the drilling fluid to ascertain information about the drilling process (commonly referred to as mud logging).

PML also supplies gas analysis systems at the surface of the site to provide early detection and evaluation of reservoir gases. Local PML data-acquisition systems can interface with other systems, such as measurement while drilling, thereby acting as a central data repository for all important wellsite information.

PML Exploration Services selected InduSoft Web Studio as a solution that would enable it to take advantage of cloud technology. This PC-based human-machine interface and supervisory control and data acquisition (SCADA) software package easily configures web-based solutions, facilitating remote access to information. The software’s 240 native drivers communicate with every major brand of programmable logic controller (PLC), as well as offer OPC support, making it easy to configure an application to communicate with any new equipment, regardless of the manufacturer.

PML developed the Edge solution for data acquisition, display and remote access to wellsite information. Remote well operators use InduSoft Web Thin Client and other features to keep track of changes by pulling and viewing live data and reports from the cloud. At the rig, PML employees track changes in total gas, gas constituents and other information using the software’s chart and trending functions.

The data from the SCADA software is sent via a satellite connection to the cloud, where it can be viewed with devices (smartphones, tablets, thin clients, PCs, etc.) enabled by InduSoft’s Web Thin Client and Studio Mobile Access features.

InduSoft Web Studio’s native and flexible security system allows PML to consolidate data from several wells in the cloud, while still maintaining tight security by restricting data access based on user credentials. GP

Comments