What’s new in gas processing technology

H. Meche, Associate Editor

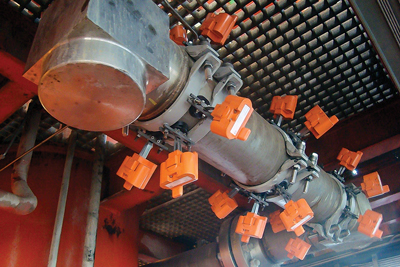

Metal loss measurement in remote locations

Permasense’s integrity-monitoring systems use sensor technology to continuously monitor metal wall thickness and deliver high-integrity data from remote and inhospitable environments. The quality and frequency of the measurements enable detection of corrosion and erosion activity before failure occurs.

The systems are suited for offshore applications, negating the need to send inspection personnel into hazardous situations offshore, and providing data to the desks of integrity/operations engineers, either on the platform or on land. The marine version of the nonintrusive wall-thickness monitoring sensor features standard or compact form factors (the compact form factor sensor offers a height from the pipe wall of only 200 mm), metal components made of duplex steel for increased resistance, a tip seal to protect pipe from external corrosion at the pipe-sensor contact area, an IP67 rating and flexible sensor mounting solutions.

Permasense systems monitor sand erosion in offshore gas production facilities—a particularly valuable application, as unpredictable sand content can erode platform pipework. High erosion rates can occur in areas of high velocity or with sudden changes in flow direction. In gas production platforms, this is usually directly after the choke, where the flowrate is increased; on the outside radius of bends; or just downstream of bends, especially straight after the choke or downstream of blind tees.

Analyzer continuously measures hydrocarbons

GOW-MAC Instrument Co.’s Series 2300 total hydrocarbon analyzer is a 2,300-microprocessor-controlled instrument for continuously measuring concentrations of hydrocarbons. Using an optional catalytic methanizer, it can measure carbon monoxide and carbon dioxide in gas streams.

The analyzer uses a flame ionization detector (FID) where ionized carbon atoms are produced when burned in a hydrogen flame. Ionized atoms are detected and displayed as parts-per-million (ppm) or parts-per-billion (ppb) concentrations on a high-resolution LCD touchscreen. An accompanying membrane keypad enables straightforward navigation through settings and functions.

The instrument operates on either zero-grade hydrogen (H2), a 40% or 60% H2/nitrogen mix, or a 40% or 60% H2/helium mix. It features auto ranging from 0 ppm to 20,000 ppm; auto zero and auto calibration; programmable relays for concentration alarms, events and diagnostics; electronic flow control of air, fuel and sample gas; real-time data logging; a flame-out indicator with auto shutoff of gases for safety; an array of optional output capabilities; USB and Ethernet; and MODBUS and PROFINET (read-only) communication protocols. Samples can be introduced by an optional internal pump or by pressurized tanks.

Gas filter lines handle high pressure

Xebec Adsorption Inc.’s three new X-Series filter lines accommodate pressure ranges up to 290 pounds per square inch (psig), 725 psig and 6,000 psig (20 barg, 50 barg and 420 barg).

The X-Series has been performance-validated according to International Organization of Standardization (ISO) 8573 quality standards and ISO 12500 test methods by Institut für Energie-und Umwelttechnik eV, an independent verification body.

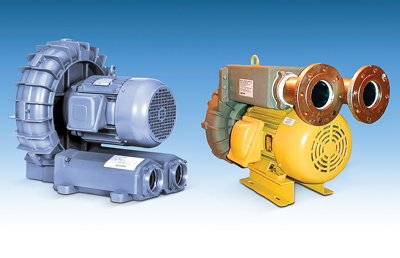

Blowers safely handle corrosive/explosive gases

AMETEK Precision Motion Control’s ROTRON Chem-Tough regenerative (side-channel) blowers safely handle corrosive and/or potentially explosive gases. The blowers operate in environmentally challenging, chemically corrosive and potentially hazardous conditions, including methane extraction and flaring.

The blowers use regenerative air technology to develop proper air pressures and vacuums. This is accomplished without the higher energy and maintenance costs associated with larger multistage or positive-displacement blowers and compressors. An extensive product range allows users to achieve ideal flows, pressures and vacuums.

Rugged construction features include nickel-plated components and 303 stainless steel motor shafts and hardware. Custom seals ensure leak containment. Use of low-friction polymers provides permanent “dry” lubricity. The blower’s low-noise, high-efficiency aerodynamics are achieved through its lower-speed alternating-current induction motors. These ATEX-certified, explosion-proof motors are designed for harsh environments, and they are available in all international voltages.

Complete portable emissions analyzer

The E5500 combustion analyzer provides emissions monitoring for regulatory and maintenance use in boiler, burner, engine, turbine, furnace and other combustion applications. The complete portable tool also includes electrochemical gas sensors (O2, CO, NO, NO2, SO2) and is low-nitrogen-oxides (NOx) and total-NOx capable.

It has a real-time PC software package with wireless communications, along with other features, including a wireless remote printer; external water-trap assembly; stack gas and ambient air temperature measurements; draft and differential pressure measurements; and calculated values for efficiency, excess air

and CO2%.

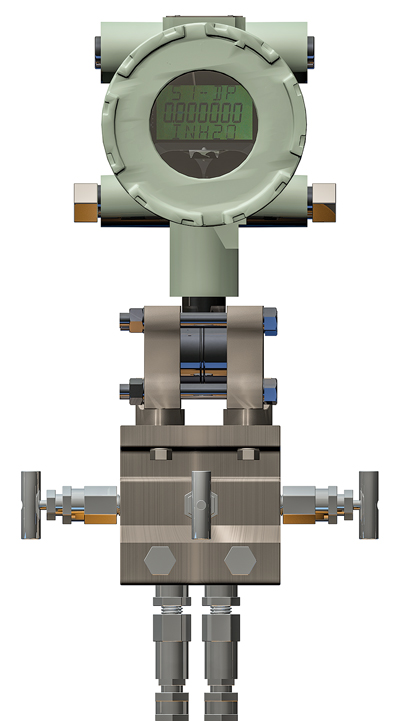

Pressure transmitter reduces energy use

Newgate Instruments’ multivariable pressure transmitter (MVT), the JT400, uses

five times less energy than traditional MVTs. The JT400 transmitter is reportedly the only MVT with an integrated autonomous power system contained within an explosion-proof housing. It can operate for up to 12 years without requiring a battery change, and the solar-powered JT400 version can operate up to 200 days without sunlight.

The JT400 transmitter logs data of 15-minute averages up to 30 days for periodic transmission or local download. Additionally, it maintains industry-leading performance accuracy, is the only MVT to offer a local USB port for convenient data download, is compatible with all pipeline equipment, and can be installed to replace any existing transmitter or on new natural gas wells.

Protect LNG transport assets against spills, fires

Gas transported as LNG is typically stored at temperatures of −260°F. Steel becomes brittle at roughly −22°F, exposing the transport asset to cracks, corrosion and potential cryogenic spills. Any type of spillage caused by this process, if the LNG is vaporized, can create a potential fire risk. Syntactic epoxy insulation offers protection against cryogenic liquid contact. This epoxy binder system is filled with insulating microspheres, which are typically wet-applied by hand or spray.

Sherwin-Williams’ FIRETEX M89/02 is a seamless, high-solids epoxy-resin-based insulative epoxy. It was developed to provide protection against both cryogenic/LNG spillage and hydrocarbon fires, and it can be used at operating temperatures from cryogenic to 300°F. The insulative epoxy has been tested for freeze-thaw cycling, impact resistance, flexibility, compressive strength and adhesion, as well as for resistance to saltwater and freshwater immersion.

Ongoing testing by Sherwin-Williams revealed no breakdown of coating in large-scale testing. FIRETEX M89/02 epoxy was proven to withstand a cryogenic spill simulation in which systems were immersed in liquid nitrogen and then hydrocarbon fire-tested per UL 1709 for 60 minutes.

FIRETEX M89/02 epoxy can be used in conjunction with the FIRETEX M90 Series epoxy to provide protection against hydrocarbon and jet fire following a cryogenic spill.

www.protective.sherwin-williams.com

Enclosed combustors are environmentally compliant

As a result of interviews with its major shale play clients, AEREON developed its Quad-O Design Enclosed Combustor (QDEC) as a solution to meet demands for an environmentally compliant line of combustors. The QDEC is a completely smokeless system, offering quiet operation with no visible flame, reducing emissions to comply with New Source Performance Standard (NSPS) Subpart OOOO.

The system does not require electrical, steam or assist gas utilities to achieve smokeless performance. Also, with low power consumption and an optional solar-powered ignition panel with nine-day battery backup support, the QDEC offers reliability in remote installations.

System inspects tank welds swiftly

The Applus RTD Rayscan Tankscan, a real-time digital radiographic inspection system, enables a full inspection of LNG storage tank welds in a single-scan movement, producing an image of each weld. No film chemical processing is required, and a steady scanning system is used for dynamic examination.

The system is suitable for both horizontal and vertical welds, and its rigid frame helps maintain alignment between the X-ray source and the digital line detector. This process offers savings by reducing both time spent on the examination of each weld and the number of operators required.

The product has been designed to avoid vibrations,

with a rigid frame and support wheels. A safe working distance of only 3 m from the frame is also achieved with a protective shield that surrounds the X-ray source, beam and detector.

Ultrasonic flowmeters improve accuracy

Emerson Process Management’s Daniel multi-path gas and liquid ultrasonic meters feature a next-generation electronics platform. The new JuniorSonic one-path (3411) or two-path (3412) and SeniorSonic four-path (3414) gas ultrasonic meters can be used for numerous flow measurement applications. The new four-path (3814) liquid ultrasonic meter expands on its predecessor’s functionality and performance, to offer improved reliability for custody-transfer applications.

With faster flow-sampling rates, the new electronics platform increases the data set used to calculate average velocity, allowing recognition of changing flow dynamics. Access to high-volume data capture, as well as detailed flow parameters (pressure, temperature and gas composition) allow the meter to act as a redundant flow computer.

Improved calculations for auditing or invoice resolution are enabled by the electronics’ rapid delivery of key data from the meter’s audit trail. The audit trail complies with American Petroleum Institute standard 21.1, and it is supported by a standard 128-megabyte nonvolatile memory. Access to alarms, events and configuration changes is provided in seconds.

Additional features include a compact circuit board that simplifies field removal and reinstallation; retrofit Daniel legacy ultrasonic meters to enable future upgrades; remote access support, as well as true 100BaseT fast Ethernet connectivity, T-20 Series transducers, and updated MeterLink configuration and diagnostic software.

Comments