Ichthys LNG combines three mega-projects in one

L. Bon, Ichthys project, Perth, Australia

In 2014, the US$34-billion (B) Ichthys LNG project (Fig. 1), operated by oil and gas company INPEX, will celebrate its 50% milestone and move into its peak construction phase. Just over two years ago, in January 2012, INPEX and international oil and gas company Total reached a final investment decision on what is now one of the most significant energy projects under development in the world. With the gas and condensate field located offshore North West Australia, this world-class development includes complex offshore and subsea facilities and a two-train LNG plant in Darwin, with an overall lifespan of more than 40 years.

|

|

Fig. 1. Bladin Point in August 2013. The Ichthys LNG project will soon celebrate one |

In the two years since the Ichthys LNG project was given the green light, INPEX and Total—with respective stakes of 66.07% and 30%—have welcomed Ichthys LNG buyers Tokyo Gas, Osaka Gas, Chubu Electric Power and Toho Gas as joint venture (JV) participants in the project. Activities have been progressing as outlined in the project plan, and intense engineering, procurement and fabrication efforts have been ongoing in Australia and other locations around the world.

The Ichthys LNG project is expected to produce 8.4 million metric tons per year (metric MMtpy) of LNG and 1.6 metric MMtpy of LPG, along with approximately 100,000 barrels per day (bpd) of condensate at peak. First production is scheduled to commence by the end of 2016.

From the field to the market

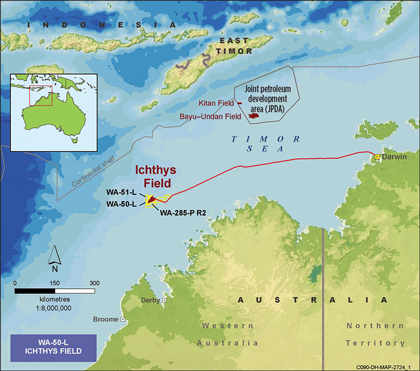

The Ichthys reservoirs (Fig. 2) are situated in the Timor Sea, approximately 220 kilometers (km) off the West Australian coast and more than 800 km west of Darwin. For INPEX, the story began over 15 years ago, in August 1998, with the award of Exploration Permit WA-285-P in the highly prospective Browse basin.

|

|

Fig. 2. INPEX discovered the Ichthys field off the northwestern coast of Australia |

Three exploratory wells drilled during 2000 and 2001 resulted in the discovery of a promising gas and condensate field with resource estimates from two geological horizons containing proven and probable reserves of more than 12 trillion cubic feet (Tcf) of gas and approximately 500 million barrels (MMbbl) of condensate. Lying in an average water depth of 250 m, the field represents the largest discovery of hydrocarbon liquids in Australia since Bass Strait more than 40 years ago.

Australia is strategically located close to Asia, where gas demand is forecast to grow by 6%/year (yr), on average, between now and 2020. As the world’s biggest import region, taking more than 76% of global LNG production in 2013, Asia is also the fastest-expanding market. In 2020, it will remain the largest LNG consumer in the world, with annual imports estimated by Total of around 268 metric MMt. More gas projects will be needed to meet this demand.

In this context, sales and purchase agreements (SPAs), with shipments slated to begin in 2017, have underpinned the development of the Ichthys LNG project. All of the project’s production over the next 15 years has been sold, mainly to buyers in Japan and Taiwan; approximately 70% of the contracted Ichthys gas will go to Japanese utilities. INPEX and a Total affiliate will also take 1.8 metric MMtpy of LNG.

Three mega-projects in one

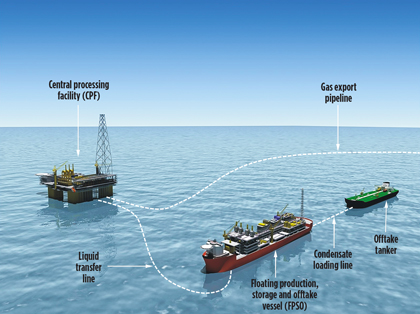

Massive is the operative word. The Ichthys development is, in fact, three mega-projects housed under one roof. The first project consists of building offshore production infrastructure (Fig. 3), with subsea facilities and two large floating platforms. The central processing facility (CPF) and the floating, production, storage and offloading (FPSO) vessel will both be among the largest in the world.

|

|

Fig. 3. The offshore facilities will consist of a subsea, multi-well development |

The second project involves laying an 889-km, 42-inch (in.) gas export pipeline from the field to Darwin, where the third project—the onshore, 8.4-metric-MMtpy LNG plant—is being built.

The offshore infrastructure includes the world’s largest semi-submersible platform, with topside dimensions of 150 m by 110 m and a combined weight of more than 100,000 metric tons. Over the 40-year initial design life of the project, the unit will collect gas from a network of up to 50 subsea production wells drilled into reservoirs 4,000 m to 4,500 m beneath the seabed. A huge FPSO—one of the largest and most sophisticated to be deployed worldwide—will be positioned approximately 3 km from the CPF to treat and export the condensate. This 336-m-long FPSO will be a weather-vaning, ship-shaped vessel that is permanently moored on a non-disconnectable turret. The turret, which is being manufactured in Singapore, is one of the most complex pieces of equipment on the project.

The FPSO has been designed with a storage capacity of nearly 1.2 MMbbl of condensate. Significant progress has been made on the offshore project over the last year, with fabrication of all major facilities now well underway. Recently, the project celebrated a major FPSO milestone with the laying of its keel, and it will soon see the delivery of the non-disconnectable turret.

Innovative infrastructure. However, these structures comprise only the tip of the iceberg. Tons of equipment and many kilometers of flexible and rigid pipelines will be installed on the seabed to gather and distribute the process fluids to, and extract production fluids from, up to 50 wells.

Subsea structure fabrication is well advanced, with the pinnacle being the 110-m-high, 6,000-metric-ton riser support structure, which will be ready for installation in September 2014. Subsea installation engineering is also progressing well, and the contractors will soon mobilize their offshore barges. The newly commissioned deepwater construction vessel Aegir is due to arrive onsite at the Ichthys field within a few months.

Looking forward, there will be much activity for the offshore project in 2014, some of which includes the start of the drilling program, the subsea installation and the pipeline-laying, as well as the progression of CPF and FPSO fabrication.

Export pipeline. Linking the offshore and onshore projects is the gas export pipeline. An 889-km, 42-in. pipeline will connect the Ichthys field to the onshore plant. When complete, it will be the fifth-longest subsea pipeline in the world and the longest subsea pipeline in the Southern Hemisphere. All 889 km of the pipeline have been produced and coated.

Soon, pipe-laying will commence in Darwin by winching onshore at the landfall site via a 3-km shore-pull. A shallow-water lay barge will then install approximately 120 km of the pipeline through Darwin Harbor and beyond, before transferring it to the deepwater lay barge. The pipeline is then laid all the way to the Ichthys field before terminating with the world’s largest subsea diver-less connector.

Onshore LNG. The onshore project in Darwin (Fig. 4) comprises two APCI-process LNG trains with a nameplate capacity to produce 4.2 metric MMtpy of LNG. The site is large enough to allow the construction of up to four additional trains. Two product-loading jetties are being constructed—one for LNG and the other to handle LPG and condensate. The project adopted a modularization strategy for the plant build, so a module offloading facility (MOF) is required to enable delivery to the site.

|

|

Fig. 4. Layout of the future Ichthys LNG liquefaction complex in Darwin. First production is expected in late 2016. Photo courtesy of INPEX. |

Construction at the Bladin Point site near Darwin continues on schedule, with huge civil works at an advanced stage. Major work is also underway on key infrastructure, including the module offloading facility (MOF), product-loading jetties, LNG, LPG and condensate storage tanks, and the combined-cycle power plant. Soon, the project will see the arrival of the first of 220 modules needed to build the process trains, the largest of which can be up to 50 m long and 30 m high, with a combined weight of more than 200,000 metric tons.

Also part of the onshore project is a temporary accommodation village for the construction-phase workforce, which will house up to 3,500 workers. In September 2013, the Ichthys LNG project celebrated the opening of the first stage of Manigurr-ma Village, as it is called in honor of the Larrakia Traditional Owners of the land. The village is being built in four stages. Stage 1 completion included 1,000 rooms and key central facilities, such as the kitchen, tavern, administration buildings and recreational spaces. Construction is scheduled for completion in mid-2014.

As part of the onshore project, dredging to deepen the shipping channel in Darwin Harbor is required. This is needed to ensure the safe passage of LNG carriers in and out of the harbor. Following the successful completion of the first phase of the program in 2013, the second and final phase is now well underway and is scheduled for completion in 2014.

Commitment to HSE is essential

Above all else, the Ichthys LNG project JV participants have a fundamental and absolute commitment to health, safety and the environment (HSE), and they have set a goal of zero harm to the workforce and to the environment. HSE is the first priority for the project, and this is embedded in everything from engineering to design, and from construction to operational readiness. This goal is in line with Total’s strong commitment to ensure the safety of the people working on its projects and to minimize its environmental footprint in Australia and all countries where Total is present.

The Ichthys LNG project has organized a charter among major contractors, both onshore and offshore, that recognizes INPEX’s value of “anzen dai ichi”—“safety number one.” The commitment to achieving zero harm is being implemented throughout all Ichthys LNG project contracts. Leaders from INPEX and its contracting companies meet every year at the Ichthys LNG project CEO and contractor HSE forums to identify and implement ways to improve HSE performance and to ensure that every leader involved in the project understands what needs to be done to deliver a safe workplace culture. From the CEOs to the workers onsite, the commitment to HSE is evident. A standout example is the onshore fabrication yards, which, to date, have recorded 18 MM worker-hours without a lost-time injury.

Just as important to the project is the environment. One example is the Ichthys LNG project’s scientific environmental program in place in Darwin, which keeps a close watch on the harbor to ensure the monitoring and recording of any changes from dredging and marine construction activities. At the end of the first phase of planned dredging work, the results of the project’s environmental monitoring programs indicated that impacts were either in line with, or less than, the original predictions.

To minimize the impact of the project on the environment, the Ichthys LNG project has committed to an AU$92 MM environmental benefits package (Fig. 5). Commitments include, among others, the conservation status of coastal dolphins in the Northern Territory, the habitat mapping for the Darwin region and the conservation management of marine megafauna in the Western Top End of Australia.

|

|

Fig. 5. The Ichthys project has committed to an AU$92-MM social and environmental offsets package to contribute to the protection and management of the marine and terrestrial environment. Photo courtesy of INPEX. |

The Ichthys LNG project JV participants have also donated AU$3 MM to Charles Darwin University to accelerate plans for the North Australian Center for Oil and Gas. A range of industry-specific courses will be introduced to help the Northern Territory become a leader in training for the oil and gas industry.

A clear contribution to Australia’s economy

Respecting the host country’s right to benefit from the development of its natural resources, the Ichthys LNG project has committed to full, fair and reasonable access for Australian industry to take part in the project.

A comprehensive industry participation plan (IPP) coordinates strategies to boost the use of local labor to expand opportunities for local business to provide goods and services, and to support and grow job and skill training across the Northern Territory and wider Australia. To date, more than 250 subcontracts have been awarded by the project’s lead onshore contractor and its Tier 1 contractors to Northern Territory-based companies. The IPP also encourages Aboriginal and Torres Strait Islander (ATSI) business participation in the project.

Along with promoting Australian industry participation, the project is committed to maximizing locally based employment, where reasonably achievable. Ichthys LNG is also developing training and education institutions, available to all Territorians, so that they may obtain qualifications to participate in the oil and gas, mining and construction industries.

Progress milestones and future challenges

While the Ichthys LNG project is progressing well and will continue to strive for its objectives of schedule, budget and quality, there are still significant development challenges ahead. Some of these challenges include:

- Driving behavior where zero harm is a core value for all working on the project

- Designing and maintaining equipment for an operational life of more than 40 years

- Engineering some of the world’s largest offshore infrastructure

- Surviving the offshore climate in the Browse basin, an area known for its cyclones.

Despite these challenges, the Ichthys LNG project will soon celebrate one of its biggest construction milestones yet—50% completion. Only two years into construction, the project is delivering significant benefits to the Northern Territory, to wider Australia and to the world. With a multi-generational lifespan of more than 40 years, these benefits will continue for decades to come. GP

|

Louis Bon, the managing director of the Ichthys LNG project, joined the project in 2013. He has more than 30 years of international industry experience with international oil and gas company Total, where he has held a variety of senior management roles across Europe, the Middle East, Africa and Asia. Prior to being seconded to the project, Mr. Bon’s most recent position with Total was vice president of operations, with responsibility for worldwide field operations and drilling activities. Previous senior roles with Total included project director of Pazflor, a major offshore deepwater development in Angola; and deputy vice president of projects and construction for all Total exploration and production projects.

Comments