Products

H. Meche, Associate Editor

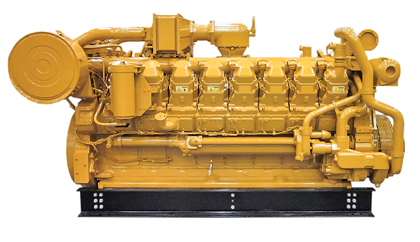

Low-emissions engine released for gas compression

Caterpillar Oil & Gas offers a low-emission engine upgrade kit for select G3516 LE petroleum engines for gas compression applications. With the upgrade kit, existing engines can be modified to a lower-emissions configuration, enabling operation at 0.5 grams/brake horsepower per hour (g/bhp-hr) or 1 g/bhp-hr, not to exceed nitrogen oxide (NOx) levels.

The engine upgrade is economic and minimally invasive. It allows the engine to offer the same power and fuel tolerance, while simultaneously increasing altitude and turndown capability.

The power rating for the G3516 LE remains the same at 1,340 bhp at 1,400 rpm. The upgrade kit uses existing technology and proven parts. Trained experts at local engine dealerships are available to bring existing engines up to the latest technology level, regardless of the engine’s lifecycle.

Kit components include a two-stage aftercooler, a venture fuel mixer, turbochargers, an oil cooler, air cleaners, a gas shutoff valve and software. Existing engines must have the ADEM A3 engine control module, air-fuel-ratio control and an NOx sensor. Upgrade kits are available to bring engines up to this configuration.

Wireless monitor gives real-time gas detection

RAE Systems Inc. has introduced what it claims to be the industry’s first wireless, portable, four-gas pumped and diffusion gas monitor. The QRAE 3 monitor is a one-sensor to four-sensor gas monitor that provides continuous exposure monitoring of oxygen, combustibles and toxic gases. These gases include hydrogen sulfide, carbon monoxide, sulfur dioxide and hydrogen cyanide.

The monitor is certified for use in hazardous environments. It can be used in oil and gas, environmental and other industries where exposure to toxic gas is a constant safety threat.

The QRAE 3’s wireless communication capability enables access to real-time remote instrument readings and alarm status from any location.

Real-time hazard readings can also be communicated to the ProRAE Guardian safety system and the EchoView Host closed-loop wireless system for wireless monitoring outside the hot zone, from a plant safety office or from a remote, enterprise location.

Platform offers gas chromatography alternative

Precisive LLC’s tunable filter spectroscopy (TFS) platform now features Precisive 5, a hazardous area-compliant package for unattended hydrocarbon process and natural gas analysis. The Precisive 5 gas analyzer does not require carrier or calibration gases, and it offers accurate response analytics in the presence of interferences.

The Precisive TFS platform, an infrared absorption-based online monitoring system, can be configured for composition monitoring or for measuring trace levels of hydrocarbons and volatile organic compounds. It performs multiple composition monitoring from parts-per-million to percent-level calibrations, and it has a faster response than traditional gas chromatography systems.

Other features include low maintenance; a Modbus communications interface that enables remote and unattended deployment; compliance with the North American division system (Class 1, Division 2; Groups A/B/C/D; T4; and Type 4X), the North American zone system (Class 1, Zone 2; Aex nA IIC T4; IP66; Ex nA IIC T4; and IP66) and the European zone system (EX II 3G n IIC T4 Gc); and worldwide certification to IECEx standards.

System provides leak detection for pipelines

Biffi Italia’s ELBS-20 electronic pipeline monitoring system accurately and reliably detects leaks in high-pressure and low-pressure environments. The ELBS-20 system monitors gas and fluid pipeline integrity. It can be combined with any type of valve actuator and a range of pressure sensors. The unit monitors pipeline pressure and commands the actuators to initiate the failsafe position in case of failure.

The ELBS-20 module measures safety parameters such as pressure increase/decrease and sudden drop, along with low-limit and high-limit exceeded levels. Recorded data can be downloaded to any portable electronic device through communication ports such as Bluetooth, RS485 point-to-point and RS232 interfaces.

Additionally, the ELBS-20 is said to be the only internal leak-detection device available that contains a unique, solenoid-operated valve (SOV) integrity-check function, enabling system availability to be monitored at all times. Capable of operating in temperatures from –40°C to 75°C, the unit can also manage pressures from 10 bar to 1,000 bar.

Detectors protect shale gas rigs from hazardous leaks

General Monitors’ S4000CH and IR400 combustible gas detectors offer an early-warning alert to workers. The S4000CH model’s robust catalytic-bead sensor provides precise gas detection, easy setup and use, along with simple maintenance. The IR400 infrared (IR) point detector’s self-diagnostic design prevents false alarms and process shutdowns. It monitors conditions such as supply voltage and optical path integrity. The IR400 model also features heated optics and a dirty optics indicator.

Both detectors are microprocessor-based and continuously monitor combustible gases and vapors within the lower explosive limit. All electronics are contained within explosion-proof housings. In addition, the detectors operate with a 4-20 mA signal, feature one-person calibration and can virtually self-calibrate.

Real-time wellsite emission monitoring system

Cartasite’s vaporLOCK technology monitors oil and gas storage tanks, which are said to be the single greatest source of wellsite methane emissions. Using satellite networks, vaporLOCK sensors alert well operators in real time if a tank is leaking. By enabling real-time monitoring of remote wellsites, the technology empowers operators to respond immediately to a detected leak and to take remedial actions.

Comments