New Products

Technology for controlling molecular sieve beds

Proper molecular sieve dehydration system operation is critical to operating any natural gas processing or LNG plant. The process hinges on the analyzer that tests the desiccant dryer outlet gas for moisture content. A bad measurement can be a major economic blow or even force a shutdown of the plant. In response to this need, some plant managers are turning to tunable-diode laser (TDL) analyzers. SpectraSensors in Houston, Texas has provided over 90% of installed extractive TDL analyzers.

Since a laser beam is used, there is no physical contact between the gas stream and the sensor. The measurement result is fast and accurate, and analyzer operation is nearly maintenance-free for many years. A built-in verification system emits an accurate level of moisture for field validation purposes. Coupled with a high-efficiency dryer, this validation system solves the problem of a lack of accurate field references for trace moisture analyzers.

With the TDL analyzer, plants have been able to extend time between desiccant drying regenerations by up to 20%. Fewer regeneration cycles means less thermal cycling, less thermal damage to the sieve and longer sieve life. If a plant can eliminate one extra recharge in 10 years, the savings could add up to $100,000 in sieve-replacement costs.

Electrochemical sensors can take up to an hour or more to report changes in the moisture level. In comparison, TDL analyzers measure the absorption of light and report a fresh reading every 16 seconds. They also accurately measure moisture in parts-per-billion levels.

Leak-detection analyzers map data to Google Earth

Los Gatos Research (LGR), a member of ABB Group, offers a new natural gas leak-detection system that quantifies natural gas leaks and directly maps data to Google Earth continuously.

The system combines LGR’s ultraportable methane/carbon dioxide/water (CH4/CO2/H2O) and CH4/H2O analyzers with standard anemometers for wind velocity and global positioning system detectors for geographical coordinates. Along with open-source mapping software, the system provides accurate measurements and a rapid response time.

The system’s dynamic range allows users to measure CH4, CO2 and H2O even if concentrations are significantly higher than typical ambient levels. For example, it can detect up to 10% methane without compromising sensitivity at ultra-low levels.

Unlike competitive analyzers, which require a warmup time to thermo-mechanically stabilize, the LGR system allows users to collect data as soon as the instrument starts. With license-free software, users can directly upload the measured concentrations and system parameters in real time to their own servers, and map the results directly to Google Earth. The system operates on a Windows-based laptop computer.

The portable analyzer requires little power and takes advantage of LGR’s patented technology—a fourth-generation, cavity-enhanced laser absorption spectroscopy technique. In addition, the analyzers may be locally controlled using a smartphone or tablet, remotely operated via the Internet, and maintained and cleaned by users with minimal training.

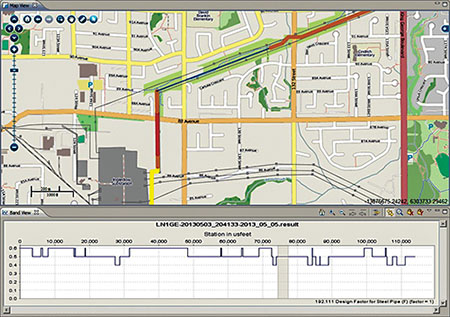

Calculator reduces pipeline failures

GE’s Smallworld maximum allowable operating pressure (MAOP) calculator enables companies to calculate the MAOP for a line/loop of steel transmission pipelines for natural gas in a verifiable, traceable and complete method. The instrument is reportedly one of the first industry solutions to seamlessly integrate MAOP calculation with geospatial information systems (GISs).

The calculator is completely customizable and can perform analysis, tracking and reporting on the data available in a pipeline company’s current GIS. By linking records to the original design or testing information, it helps pipeline companies trace data origination. It can identify a transmission pipe’s specific MAOP through its database of verifiable records. When MAOP data for a pipe cannot be located, the MAOP calculator can choose the worst-case scenario to determine its maximum pressure limit.

Calculator users can also compare assessment configurations and results, track the origin of line data and audit proof-tracking of changes to data. Pipeline companies have the ability to edit and manipulate line data to fill missing data gaps, correct data or run what-if scenarios.

The Smallworld MAOP calculator can calculate the MAOP for a line/loop in accordance with the US Code of Federal Regulations 49 CFR 192, and it can calculate the MAOP of any defined pipeline segment according to Pipeline and Hazardous Material Safety Administration (PHMSA) guidelines.

LNG flow-measurement technology for low-temperature conditions

Primary Flow Signal’s (PFS’s) differential Venturi flowmeters and orifice plates offer the reliability and comprehensive readings required in harsh environments where the process of gas liquefaction must be accurately monitored.

Venturi meters used for LNG applications meet ASME and ISO-5167 standards, and they provide standard accuracy of ±1.0% to ±1.5% (per ASME/ISO-5167) and ±0.25% or better, based on hydraulic laboratory flow calibration. Comprising carbon steel, stainless steel or virtually any machinable material requested, Venturi meters can be incorporated with various secondary instrumentation systems to satisfy any

application requirements.

Using the same principles of Venturi meters, PFS’s orifice meter plates continuously measure fluid flow in pipes. They are applicable for many diverse, existing piping schemes, and they require a lower investment for initial equipment purchase.

PFS’s metering solutions are manufactured in the US, backed by extensive laboratory and field testing. They are ISO 9001–ISO 2008 certified, and they are available with ASME S and U code stamps, as well as with European PED, Module H compliance.

System advances performance monitoring, predictive analytics

Valerus has launched Valerus COMMAND on its contract compression fleet and on facilities it owns and operates. A step change from traditional supervisory control and data acquisition (SCADA) and monitoring systems, it integrates remote monitoring and analytics, enterprise asset management (EAM), standard operating procedures and technical expertise to deliver actionable information and insight. This improves safety, service, availability, reliability and environmental compliance of surface facilities.

Valerus has partnered with Enbase Energy Technology to develop the performance monitoring and analytics portion, or predictive SCADA, that automates the system’s real-time data, notifications and daily reports.

In addition, Valerus has opened a COMMAND Center in Houston, Texas.

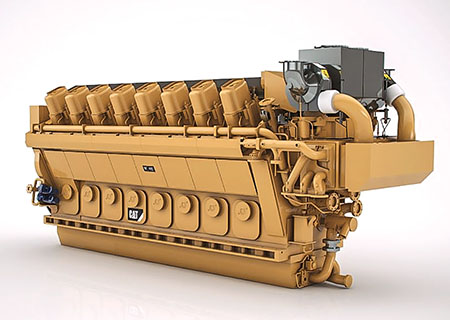

Engine upgrades optimize load acceptance

Upgrades to Caterpillar Global Petroleum’s GCM34 engine series include an enhanced control strategy with a new closed-loop air-to-fuel ratio feedback system. Key control strategy changes have improved the engine’s starting and load acceptance ability, as well as heightened engine performance under varying site conditions. Additionally, upgrades to cylinder heads, check valves, gas admission valves and spark plugs offer extended maintenance intervals and improved durability.

Built using the proven Cat diesel platform, the GCM34 engines are used in natural gas storage, gas pipeline compression and gas reinjection services worldwide. Available in 12- and 16-cylinder configurations, the GCM34 engines provide 6,135 brake horsepower (bhp) at 750 revolutions per minute (rpm) and 8,180 bhp at 750 rpm, respectively. The engine has a speed turndown capability of 40%, delivering full-rated torque from 450 rpm to 750 rpm. It can operate continuously at loads as low as 50% throughout the same speed range. Additionally, the 16-cylinder engine has a mechanical efficiency of over 43%, with fuel consumption rated at a factor of 5,860 Btu/bhp-hr.

Caterpillar is implementing the upgrades on GCM34 engines across North America, with the entire fleet expected to be outfitted by the end of 2013. Additionally, all future GCM34 gas compression engines will be equipped with the new configuration.

New approach to LNG storage tank construction

ABS Consulting has completed design review services for approval, in principle, of the design of Hyundai Heavy Industries’ (HHI’s) modular liquefied natural gas (LNG) storage tanks. The modular storage tank design, which was reviewed with onsite assembly and against applicable rules and standards, has been confirmed to be technically equivalent to standard onshore LNG storage tanks.

HHI is applying spinoff technology and concepts, from LNG shipping to onshore storage, for constructing and assembling modular LNG storage tanks. Most of the tank’s sections will be constructed and completed in the controlled environment of a shipyard. The tank will then be shipped to required areas around the world, allowing for minimal construction effort and time at the final installation site.

Comments