Improve gas processing assets with innovations in process modeling

R. BECK, Aspen Technology Inc., Burlington, Massachusetts

Between now and 2035, an estimated $205 billion will be poured into gas infrastructure capital assets in North America.1 Most midstream owners and operators have limited resources to conduct the engineering of these assets in-house. Nonetheless, they will be under increasing pressure to handle feasibility studies and project oversight in-house, which are the two essential aspects of any project required to keep construction and project costs under control.2 Midstream engineering work will continue to be outsourced to engineering and construction companies (E&Cs), and it will continue to be extremely dynamic. The experience to date of E&Cs is that client requirements change and, therefore, project teams need to be extremely flexible in the design and redesign of projects, particularly early in the project lifecycle.3

Fortunately, process modeling has advanced and fundamentally evolved in such a way that advanced software is well suited to meet the technical and business needs of this asset buildout, and this innovation continues.

To understand how software advances can assist in the engineering of gas assets, it is imperative to examine the evolution of process engineering software, from the modeling and design of specific parts of the gas system, to broader modeling and optimization of the entire gas processing system—including gathering, separation, dehydration, acid gas treatment, pipeline hydraulics and liquefaction.

Minimizing energy use

A standout innovation is the incorporation of energy analysis within a gas processing and production system model. Traditionally, process models are used to design and optimize one portion of a gas asset—such as a dehydration system, a gas-to-liquids (GTL) system, or a system of compressors. This model achieves a favorable design for one portion of a system. However, when different design or operating objectives need to be addressed (such as energy use optimization, emissions management, or carbon footprint minimization), either models must be combined, or separate models must be built.

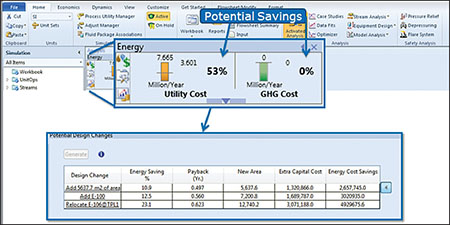

For example, energy minimization is usually achieved with the use of pinch technology, a methodology used by specialists in that arena. A recent innovation embeds pinch analysis inside the process simulator to allow a process engineer to easily compare and evaluate the energy use and carbon footprint of process alternatives without being an expert in pinch analysis (Fig. 1).

|

|

Fig. 1. Pinch technology is embedded within the process simulator. |

In another variation of energy optimization, a similar modeling approach is used to develop strategies to ensure compliance with air emissions permits in Alberta, Canada, for glycol dehydration units operated by Encana and Devon Energy. Process modeling studies enable the operators to match monitoring data to process models, accurately model facility performance, identify optimal operating strategies that reduce both glycol circulation rates and energy consumption, and ensure that emissions stay within permitted limits. This design analysis has achieved savings of about $30,000 per dehydration unit.

Optimize heat exchanger selection and sizing

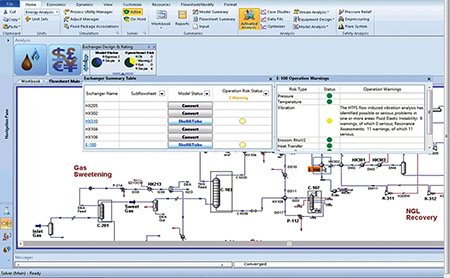

Another innovation has been the incorporation of high-fidelity heat exchanger models within the process modeling environment (Fig. 2). Heat exchangers are often critical design elements of gas processing facilities. Incorrectly designed gas processing systems, from a heat exchanger standpoint, can result in wasted energy and reduced performance.

|

|

Fig. 2. Rigorous heat exchanger models are inserted within the process simulator. |

Conversely, over-design of heat exchangers (especially high-performance heat exchangers, such as plate-fin exchangers) can result in significant excess capital costs. Incorporation of energy minimization and heat exchanger network design and optimization within the overall modeling environment can easily lead to savings of 10%–30% in energy use and a resulting reduction in greenhouse gas emissions. In one recent case study, a global E&C firm was asked to determine a feasible way to increase the capacity of a gas plant with minimal changes to plant hardware. By incorporating a plate-fin heat exchanger model within the process simulator, the company was able to identify a debottlenecking scheme that it would otherwise have been unable to technically validate to the client’s satisfaction. This scheme had a one-month payback period and increased the gas plant yield by 20%.

Another crucial innovation is the close integration of rigorous cost-estimating conceptual models with the process simulation model. The ability to determine a design’s capital and operating cost within a reasonable accuracy envelope at an early stage of design provides the engineer with the ability to discuss both technical alternatives and economic feasibility early in the project, when there is still project flexibility to make changes. (The accuracy envelope is usually B 20%–30% to achieve authorization for expenditure.)

A reasonable estimate of design cost also provides the engineer with the tools to quickly handle the engineering change process when the client’s business and design criteria change, which is typically driven by changes to on-the-ground gas supply and other operating parameters.

This flexibility is especially valuable given that gas marketplace dynamics involve fast-moving business opportunities on both the supply and sales sides, as well as capital project financing opportunities. In a recent US Gulf Coast natural gas liquids (NGL) project, an E&C firm was able to employ process modeling integrated with conceptual economics models to quickly evaluate a number of technical alternatives, understand the capital and operating cost impacts, communicate these impacts to the client, and arrive at a final design that saved the client significant capital cost. Additionally, these designs achieved an increase in gas processing capacity that was still within the constraints of the existing infrastructure. All of these improvements were accomplished in an environment where the owner’s criteria changed several times.3

Additionally, Kuwait Oil Co. saved $20 million dollars on a gas processing retrofit project by using this economic analysis technology. The operator had already selected a unit revamp approach, but a process engineer was able to convince management to briefly suspend the project to perform a comparative economic analysis of a new unit vs. a revamped unit. The process and economic models were extremely instrumental in changing the company’s direction to the implementation of a non-intuitive, but less costly, approach.4

Innovations in acid gas cleaning modeling

Acid gas cleaning is another important aspect of the engineering and operation of gas processing facilities. Benefits of accurate and correct design include capital costs (column sizing), amine costs, energy costs, regulatory compliance and operability.

The latest innovations in process modeling have applied rigorous and accurate rate-based distillation to a completely new and more accurate approach to modeling acid gas stripping. Also, accurate models that can predict performance of packed columns (which achieve significant capital cost savings) and heat-stable salt formation (which impacts operating efficiency and uptime) have been introduced. This technology is currently in the early-adopter phase.

Modeling to improve compressor operability

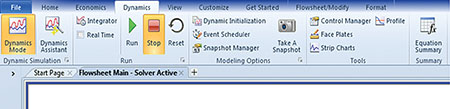

One area for operational integrity risk in a gas processing network is the compressor section. Compressors are subject to a variety of instabilities and upset conditions. Dynamic compressor models are a valuable tool in understanding upset and operational risk scenarios. Dynamic modeling is made progressively easier to adopt by integrating dynamics closely within steady-state simulators, as well as through tutorials and compressor sample models that help engineers model their compressor installations without needing to start from scratch (Fig. 3).

|

|

Fig. 3. The move from steady-state models to dynamic models. |

The payoff

Midstream and E&C organizations that are using these innovative advances in process modeling are achieving concrete results in terms of fast project cycle times (as much as 30% time savings), better use of capital (in many cases, identifying alternatives that can save 10%–20% capital investment within tight project deadlines), and significant incremental energy efficiency in gas processing and transportation. An added bonus is an improved ability to project emissions compliance risks and reduced carbon footprints.

Future directions

The innovations described here provide powerful evaluation and optimization methods to midstream companies and their E&Cs to integrate design and operations. Operators of gas processing networks are increasingly using process modeling to improve the operations of their networks, from the wellhead to the sale point. GP

LITERATURE CITED

1Deloitte Center for Energy Solutions, “The rise of the midstream: Shale reinvigorates midstream growth,” November 2013.

2LePatner, B. B., Broken Buildings, Busted Budgets, University of Chicago Press, Chicago, Illinois, 2007.

3Robertson, E., “Capital cost optimization of an NGL facility revamp,” Aspen Optimize Global Conference, Washington DC, May 2011.

4Kapavarapu, V. M. R., “Process optimization using simulation and integrated economics,” MEPEC Conference, Bahrain, October 2011.

RON BECK is the engineering product marketing manager for Aspen Technology Inc. He has worked with Aspen Technology for five years and is the marketing manager for aspenONE Engineering. Mr. Beck spent 10 years in a research and development organization that was commercializing fluidized bed technologies, enhanced oil recovery methods and environmental technology. He has 20 years of experience in the development, adoption and marketing of software solutions for engineering and plant management. He has been involved with the development of integrated solutions for several global chemical enterprises. At Aspen Technology, he has also been involved with Aspen’s Economic Evaluation products. He is a graduate of Princeton University.

RON BECK is the engineering product marketing manager for Aspen Technology Inc. He has worked with Aspen Technology for five years and is the marketing manager for aspenONE Engineering. Mr. Beck spent 10 years in a research and development organization that was commercializing fluidized bed technologies, enhanced oil recovery methods and environmental technology. He has 20 years of experience in the development, adoption and marketing of software solutions for engineering and plant management. He has been involved with the development of integrated solutions for several global chemical enterprises. At Aspen Technology, he has also been involved with Aspen’s Economic Evaluation products. He is a graduate of Princeton University.

Comments