New Products

Two-wire magmeter comparable to four-wire device

Endress+Hauser’s Proline Promag 200 electromagnetic flowmeter

Endress+Hauser’s Proline Promag 200 electromagnetic flowmeter

is a two-wire magmeter that claims to offer the same measuring performance as a four-wire magmeter. The Promag H200 is available in line sizes of 1⁄12 in. to 1 in., and Promag P200 is available in line sizes of

1⁄2 in. to 8 in. for measuring flowrates of conductive fluids with an accuracy of ±0.5% of range and a repeatability of ±0.2% of range.

The flowmeter operates in process temperatures from –40°F to 304°F. It offers welded, threaded, hygienic and flanged connections that meet EN/DIN PN 16-40, ASME B16.5 Cl 150 and Cl 300, as well as JIS 10K and 20K process-connection pressure ratings.

The Promag 200 does not need a separate power source for installation. It is intrinsically safe, requiring no seals or external enclosures for installations in hazardous areas. Approvals include ATEX, IECEx and cCSAus for installations in Class I, Division 1 and 2 groups, and for Zones 1 and 2. It also meets IEC 61508 SIL, ANSI and NAMUR safety requirements.

Output is a two-wire 4-20 mA signal with HART or a pulse/frequency/switch output. The HART option’s two-way information capabilities include diagnostics and instrument status. The magmeter’s local four-line text display has touch control, guided menus, startup wizards for setting up applications and displays for information on causes and remedial measures.

A HistoROM module in the Promag 200’s transmitter housing saves device data and configurations

automatically in nonvolatile memory. It enables quick and easy flowmeter replacement without loss of data,

and can also transfer configuration data to a replacement flowmeter.

www.us.endress.com/two-wire-flow

Detector features HART communications protocol

General Monitors’ Gassonic Observer-H ultrasonic gas leak detector is said to be ideal

for detecting gas leaks in pressurized systems.

The detector features HART communications, Modbus with single-transfer and block-transfer modes, and Emerson AMS Intelligent Device Manager support and event logging.

It is ATEX, IECEx, FM and

CSA hazardous-area certified,

and safety integrity level (SIL)

3 suitable.

The Observer-H detector identifies gas leaks by sensing the airborne ultrasound emitted from leaking gas at high pressure. It is suitable for detecting gas in open, well-ventilated areas.

Responding to the gas release source rather than to the dispersed gas, the detector is not influenced by changing wind directions, gas dilution or leak direction. With its wide coverage zone, the Observer-H detector can cover up to a 20-meter (m) radius and detect leaks as small as 0.1 kilograms/second.

The instrument’s high-pass filter removes frequencies below 25 kilohertz (kHz), eliminating interference from audible sound; and simultaneously sets the alarm trigger level above the ultrasonic background noise. Leaks are detected at a frequency range of 25 kHz–70 kHz at a dynamic range of 58 decibel (dB)–104 dB.

Other Gassonic Observer-H features include failsafe operation and an advanced stainless steel microphone; a Senssonic integrated acoustic self-test that verifies electric circuit and microphone integrity every 15 minutes; and a stainless steel, AISI 316L explosion-proof housing that offers corrosion resistance in the harshest environments.

Consider base heating reliability in LNG tank construction costs

Tank base design is crucial when dealing with extremely low liquefied natural gas (LNG) application temperatures. Freezing and frost formation at the tank base or the soil below may cause cracks to develop. Cracks can deform the tank base and cause foundation damage. Electrical heating of the tank base helps prevent the occurrence of these cracks.

Eltherm GmbH specializes in the design, engineering and supply of reliable, energy-saving and complete turnkey base-heating system solutions for LNG storage tanks. Its complete line of heating cables includes resistance and parallel heating cables based on continuous wattage and self-regulating technology. Thus, eltherm offers a custom-fit heating solution for cryogenic tank applications.

The choice of cable technology depends on foundation construction, ambient conditions and technical factors. Regardless of the type of heating cable used, the most important performance requirement is that the heating system continues to operate during partial or total failure. This requires the design and installation of a redundant system that is identical to the primary design.

The company provides heating cables for highly corrosive environments, and offers products with high chemical resistance, ensuring long product lifecycles and minimum maintenance requirements. Cables for LNG applications are fully certified for hazardous areas, and are designed and manufactured in accordance with many internationally recognized standards, including VDE requirements.

Implementing efficient control and monitoring technology is vital for safe and effective heating system operation. Heating system control is generally designed for two modes of operation. In the standard mode, the heating system shuts down when a primary power failure occurs. This operating mode is acceptable for heat-traced components in noncritical plant areas, or in areas where possible temporary power outages do not affect normal plant operation. In the second operating mode, heating circuits that are considered to be critical are connected to backup power systems (essential generator operation) in case of primary power failure.

Free eLearning pipeline leak course aids engineers

KROHNE’s free eLearning course aims to help engineers understand how leak-monitoring systems work. It comprises two course modules covering several pipeline leak-detection topics.

The first module describes historical development, leak-detection system requirements, causes of leaks, leak-detection options, non-continuous leak detection, continuous external leak detection and continuous internal leak detection. The second module features leak localization, human-machine interfaces, additional leak-detection functions and typical leak-detection system applications.

The course is part of the KROHNE Academy online, a free online training tool covering topics in the industrial process-measurement field. It is applicable for staff who encounter various measuring tasks daily, as well as students or anyone wishing to stay current with measuring technology and applications in technical facilities.

Oxford Catalysts to design BTL plant

Oxford Catalysts Group has been selected as the Fischer-Tropsch technology provider for the design and possible construction of a commercial biomass-to-liquids (BTL) plant in the US. The BTL project was awarded a $4.1 million (MM) grant from the US Department of Defense (DoD), under the Defense Production Act Title 3 Advanced Drop-in Biofuel Production Project. This project will help fund detailed engineering for a 1,100-bpd BTL facility, and offer an opportunity to apply for an additional grant of up to $70 MM to construct the plant.

The proposed BTL facility will be led by Red Rock Biofuels (a subsidiary of IR1 Group LLC), an experienced biofuels project developer. It will be located in Oregon and will be designed to convert approximately 170,000 tons per year of forestry-derived biomass into approximately 1,100 bpd of liquid transportation fuels.

Preliminary engineering is complete, and the project is expected to progress through detailed engineering and design over the next nine months, with the aid of the DoD grant. Following successful completion of the detailed design phase, IR1 Group plans to apply for additional grant funding to support construction.

Cold-weather additives enhance GTL diesel

Lubrizol has an agreement to supply cold-weather diesel fuel additives for Greyrock Energy Inc.’s gas-to-liquids (GTL) technologies. The additives will allow Greyrock to meet seasonal and regional specifications for diesel sold and distributed in the continental US.

According to Greyrock, Lubrizol produces a zero-sulfur, high-quality diesel fuel that exceeds ASTM D975 standards in critical areas such as cetane, sulfur and lubricity. Through its engagement with Greyrock, Lubrizol is expanding its portfolio to include synthetic fuels produced from natural gas.

Lubrizol’s expertise in cold-flow technology will help enable the year-round production and effectiveness of Greyrock’s new diesel fuel technology. The partnership will contribute to increased domestic fuel production availability and provide fuel flexibility during the critical winter season.

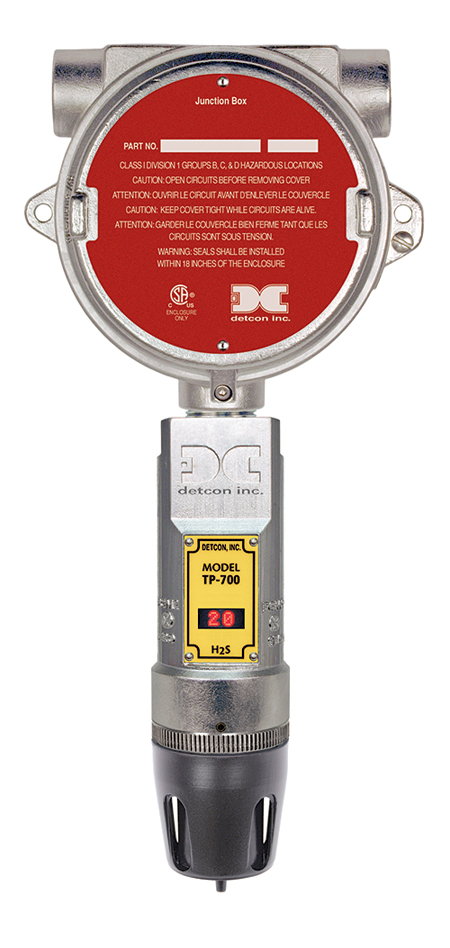

Gas detector certified for functional safety

Exida has issued a functional safety certification per IEC 61508 for the Detcon TP-700 hydrogen sulfide gas (H2S) detector. According to exida, the TP-700 design process met SIL 2 requirements, showing a good level of design integrity. The failure modes, effects and diagnostic analysis (FMEDA) was verified with solid field failure data and fault-injection testing.

Exida has issued a functional safety certification per IEC 61508 for the Detcon TP-700 hydrogen sulfide gas (H2S) detector. According to exida, the TP-700 design process met SIL 2 requirements, showing a good level of design integrity. The failure modes, effects and diagnostic analysis (FMEDA) was verified with solid field failure data and fault-injection testing.

The TP-700 detector is a smart sensor that is suitable for applications in refining and petrochemical plants, oil and gas production sites, wastewater-treatment plants and others. It features input/output protection; an electro-polished, 316 stainless steel housing; fully encapsulated electronics; and dual-layer surge protection. Other features include:

- Waterproof, corrosion-proof and vibration-proof

- Modular design and plug-and-play components

- Quick thread release (for sensor replacement)

- Integral calibration port.

Comments