Advancements improve custody measurements for LNG

A. KENBAR, the National Engineering Laboratory (NEL), East Kilbride, Glasgow, UK

Total global natural gas demand is estimated to have grown by about 2.7%/year (yr) since 2000. However, global LNG demand has risen by an estimated 7.6%/yr over the same period, almost three times faster. LNG demand growth is expected to stay strong, particularly to 2020. While a wide range of forecasts exists, a broad consensus of industry analysts predicts average annual growth of around 5%/yr–6%/yr for LNG.1

This growth in demand will be met by the expansion of existing liquefaction plants and the construction of new plants, as well as by the use of small-scale LNG plants incorporated into floating, production, storage and offloading (FPSO) vessels. The latter approach to LNG production will make it more akin to crude oil production than ever before, with LNG production being directly associated with specific gas fields.

Measuring LNG custody transfer.

The high energy density of LNG means that it can be easily transported by ships from areas of production to areas of need, and the practice for measuring what is delivered to, or received from, a ship’s tanks is observed according to the handbook of the Groupe International des Importateurs de Gaz Naturel Liquéfié (GIIGNL), or, in English, the International Group of Liquefied Natural Gas Importers.

The GIIGNL handbook is a best-practice reference book; it is neither a standard nor a specification. Recently, a new International Organization for Standardization (ISO) standard (ISO 10976:2012) describing a procedure for the measurement of LNG quantities aboard LNG carriers was released, although it has not overridden the GIIGNL handbook. As a result, the application of ISO 10976:2012 is subject to agreement between involved parties.

The calculation of LNG energy transferred requires the measurement of LNG volume in the ship’s tanks as well as the density and gross calorific value (GCV), which are made on the basis of the average composition of the LNG obtained from sampling and gas chromatography analysis. While some challenges with effective measurement are related to the measurement of the LNG volume, the main challenges are related to the LNG composition obtained from such sampling. The GIIGNL estimates an overall uncertainty in the measured LNG energy transferred of ±0.76%.

The accuracy of LNG composition obtained from sampling has a direct influence on the accuracy of calculated density and GCV and, subsequently, on the accuracy of LNG energy transferred. The LNG shipment value is often in the range of

€40 million (MM)–€50 MM. Therefore, a small error in the determination of the GCV and the density of the LNG has a significant financial impact on the exporter/importer. A 1% error in energy transferred equates to €400 thousand (M)–€500 M

in misallocation during custody transfer.

The density of LNG is calculated on the bases of the measured composition, temperature and pressure. Important sources of uncertainty are the choice of the correct equation of state, as well as the accuracy of temperature and composition measurements.

LNG measurement challenges.

In principal, better accuracy can be achieved by direct measurement of the LNG flowrate, rather than by measuring the volume in tanks. However, the nature of LNG presents substantial challenges for flowmeter technology, the biggest of which is the cryogenic temperature at which LNG exists (i.e., approximately –160°C).

Flowmeters are usually calibrated using water at ambient temperatures; however, due to the international scarcity of cryogenic test facilities, combined with the complexities of testing under low-temperature conditions, little independent research has been done to establish if flowmeters remain accurate under the extremely cold conditions in which LNG exists.

At present, the development of cryogenic flowmetering has focused on ultrasonic and Coriolis techniques. While these are promising technologies, a number of issues—including lack of cryogenic calibration facilities and inadequate means for quantifying installation effects (in particular, for ultrasonic meters for fiscal applications)—have yet to be addressed.

A lack of calibration facilities is presently addressed by the development of alternative calibration approaches based on the use of existing calibration facilities and corrections to account for cryogenic conditions; however, a more reliable approach must be developed. This is the main reason why LNG flowmeters are presently used for allocation and control but not for custody-transfer measurement.

To address these issues, the UK National Measurement System (NMS), in partnership with a private technical consultancy, has been carrying out research to help the LNG industry establish a framework of measurement standards and capabilities. This research has been conducted through the NMS Engineering and Flow Program and, more recently, through participation in the European Metrology Research Program (EMRP). The former program focused on the development of inline metering technologies, while the latter covered all aspects of LNG metrology.

European metrology program for LNG.

The EMRP is a metrology-focused European program of coordinated research and development that facilitates closer integration of national research programs. The project, which ran for three years starting in May 2010, is jointly funded by the European Commission and the participating National Measurement Institutes (NMIs).

The EMRP is delivered through projects focused on improving the European infrastructure for metrology, and provides measurement solutions to particular sector needs. The research is being executed in close collaboration with industry and has established an advisory group to maximize the benefits for industry. The program’s overall goal is to accelerate innovation and competitiveness in Europe while continuing to provide essential support to underpin the quality of life.

The EMRP’s LNG project addresses issues with state-of-the-art measurement technology using tank-gauging methods, as well as flow measurement with ultrasonic and Coriolis flowmeters. The main objective is to significantly reduce uncertainty in LNG energy transferred during custody-transfer processes. The project estimates an equivalent economic value of an uncertainty reduction of 0.5% to be approximately €60 M/yr

on the total amount of LNG imported in Europe.

|

|

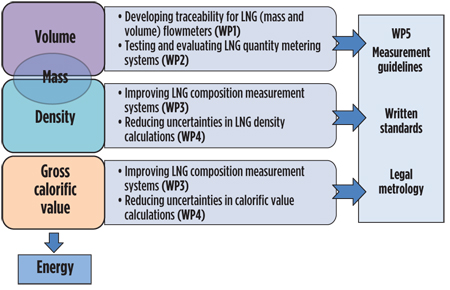

Fig. 1. EMRP work packages. |

EMRP work packages. As the EMRP deals with all aspects of LNG metrology, the work is broken down into five main work packages to ensure efficient execution of the project (Fig. 1).

The knowledge and experimental data obtained from the first four work packages feed into the fifth work package, creating impact. The information will be presented to industry through various international committees and in the form of guidelines, new international standards and other publications.

Developing measurement traceability.

The EMRP is developing the required knowledge and experience for the building of a full-scale LNG calibration facility by adopting a staged approach. The first and present stage is focusing on the development of a small-scale, primary LNG flow standard that handles flowrates up to 25 m3/hr. This is followed by the development of a mid-scale flow standard that handles LNG flowrates up to 200 m3/h, using boot-strapping techniques and input from the small-scale, primary standard and the independent proving system. The mid-scale system will be useful for small LNG applications, such as road tanker refueling.

The realization of the full-scale facility crucially depends on the outcome from the small-scale and mid-scale standards. The construction and commissioning of the small-scale flow standard has been completed, although more effort is required to achieve the target uncertainty. The initial design of the mid-scale system has been completed, but the construction of the facility will be funded under a separate project.

In addition to the above methods, a proprietary cryogenic flowmetering technology is being explored as a promising alternative to ultrasonic and Coriolis flowmetering. This flow-measurement technology already has been demonstrated in high-pressure natural gas, with an uncertainty of 0.1%–0.2%, but its application to cryogenic temperatures is challenging and under investigation.

Since the development of a full-scale LNG calibration facility will take time, the EMRP is assessing an alternative approach for calibrating LNG flowmeters. This approach focuses on the development of an economic calibration concept that transfers calibration with a fluid (such as water) at ambient conditions to cryogenic conditions by applying the appropriate corrections. This concept will be supported through testing using the small-scale and mid-scale facilities. This calibration scheme is presently used by industry, but it requires independent validation.

LNG composition measurement.

The calculation of the density and the GCV of the LNG transferred are made on the basis of the average composition of the LNG. This composition is obtained from LNG sampling and chromatographic analysis.

The sampling stage is the most important point of the LNG measurement sequence, as unrepresentative samples are responsible for the majority of errors that occur in the energy transferred calculation. Therefore, the sampling procedure must be consistent throughout the entire operation to ensure representative results.

|

|

Fig. 2. LNG sampling probes with effective (right) and less effective (left) insulation. Photo courtesy of Enagas. |

Full assessment of LNG sampling systems was carried out in the EMRP, and recommendations for improvement were made where applicable, including the enhancement of the ISO 8943:2007 standard. This included initial assessment of the uncertainty associated with the LNG sampling and vaporization system, as well as subsequent analysis by gas chromatography (Fig. 2).

Assessment of density calculation methods.

New and more accurate density reference data is being produced in the EMRP to assess the many available density calculation methods that are based on old reference data.

|

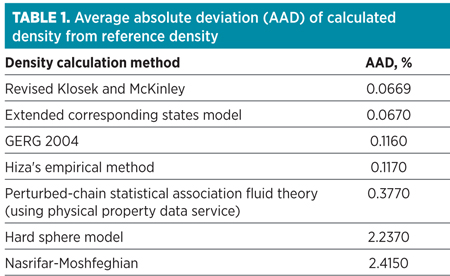

Comparison of several density calculation methods using available data for measured density show that the method adopted by the LNG industry—the revised Klosek and McKinley method—appears to give the best accuracy for LNG density calculations. The extended corresponding states model produced similar results; however, the former method is much simpler to use (Table 1).

|

|

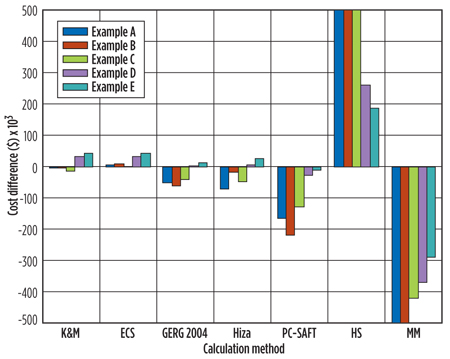

Fig. 3. Financial impact of the use of an inaccurate density calculation. |

The financial implications of different methods being applied to a cargo were evaluated for five LNG examples of known reference density and composition, with methane content ranging from 81%–97%. The financial impact of using an inaccurate density calculation method was found to be significant (Fig. 3).

The comparison between methods using the new reference data is imminent, and the most accurate method will be recommended for custody transfer in the near future.

Dissemination of information.

The new results from this project are disseminated to international organizations in the form of guidelines and standards related to LNG metrology. The challenge is to create a significant impact that facilitates international acceptance of the project results. The international working groups from the GIIGNL, the ISO, the European Committee for Standardization (CEN) and the International Organization of Legal Metrology (OIML) are collaborating to achieve this goal.

The project's impact will be maximized by organizing workshops and conferences, presenting the results at conferences and publishing the information in scientific and key user journals. Two successful workshops have already been organized. The first workshop was held in Sweden in 2010, and the second took place in the UK in 2011. These events, which attracted delegates from around the world, presented excellent platforms for sharing information and experience between the project partners and the LNG industry.

The final conference and workshop for this project will be held in Delft, the Netherlands, from 17–18 October 2013. More information on this event and the EMRP project can be found on the project website at http://www.lngmetrology.info/. GP

LITERATURE CITED

1“Global LNG: Will new demand and new supply mean new pricing?” Ernst & Young, 2013.

ASAAD KENBAR is a principal consultant at the National Engineering Laboratory (NEL), a provider of technical consultancy, research, measurement, testing and flow-measurement services to the energy industry and to government. NEL, part of the TÜV SÜD Group, is a global center of excellence for flow-measurement and fluid-flow systems, and the custodian of the UK's National Flow Measurement Standards.

Comments