Optimize throughput of gas pipelines and facilities with intelligent software

A drop of liquid. An ice formation. So small and yet so potentially costly and damaging to the operations of gas facilities and pipelines. Unwanted hydrates or liquids can clog pipes, reduce the process flow and damage equipment.

Gas processing technologies depend on understanding the phase envelope of the process fluid to operate efficiently and safely. Process engineers implement their designs to manage the worst anticipated phase envelope, normally resulting in less-than-optimal throughput and unnecessary energy use for typical or normal operating conditions.

To deal with these challenges, intricate calculations are needed and control actions must happen in real time.

Most operators adjust controls to operate the plant or the pipeline a safe distance from the formation of hydrates or well into the phase the process needs to operate on. This is accomplished by injecting chemicals, increasing the temperature of the gas with heaters, reducing temperatures far below what is needed, or operating well below the design capacity. The first three methods increase the operational cost and indirectly reduce throughput. The last one directly reduces throughput. Consequently, opportunities to improve yield and efficiency dissipate.

All this in an industry era marked by falling budgets for capital and operational expenditures (CAPEX and OPEX). While this is true at many gas facilities and pipelines operating today, it no longer has to be that way.

Increasing throughput and reliability. Until recently, no solution existed for the control system to adapt operations based on real-time conditions and compositions. Historically, process engineers calculated processing fluid simulations using spreadsheets on a desktop computer and shared them with the control engineers to implement. Those calculations helped ensure the plant operated in safe operating conditions, based on the expected range of the compositions of the process fluid. However, these calculations are based on safeguarding against worst-case scenarios, such as extreme temperatures or the poor quality of a raw material, and most of the time these facilities operate under much better circumstances.

Using intelligent throughput optimization software, that simulation capability can become a real-time control system activity to help prevent reliability issues and increase throughput. With insights provided by the software as the composition of the fluid being processed changes, the control strategy can be adapted to that change.

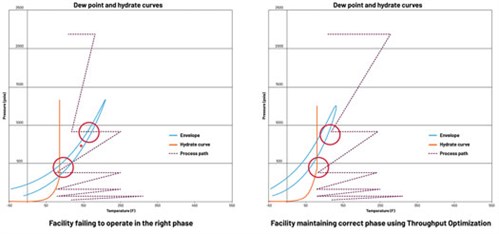

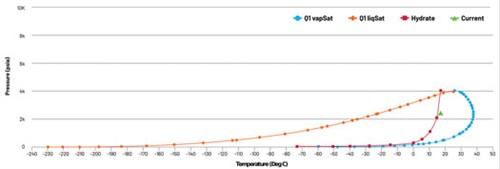

FIG. 1 shows the phase envelope and hydrate curves for a refrigeration process. Both graphs show the same facility. In the left graph, the facility is operating in an inappropriate state, with hydrates forming in one refrigeration cycle and the fluid becoming all liquid in another cycle. In the right graph, intelligent throughput optimization software is operating, providing closed-loop control to the control strategy to avoid hydrates and achieve the correct amount of cooling without causing liquids to form when they are not wanted.

|

| FIG. 1. The phase envelope and hydrate curves for a refrigeration process. Both graphs show the same facility. |

With throughput optimization software, the shape and location of the hydrate curve and phase envelopes are known in real time. The process operation can be moved to the correct side of both physical entities. The adjustments can take place either through direct closed-loop control with the control system, or the software advises the operator through an human-machine interface (HMI) and allows the operator to adjust the control system.

The software helps the facility on the right increase reliability through the prevention of shutdowns, reducing energy by optimizing the refrigeration cycle and not exceeding what is needed. Additionally, by being able to operate efficiently close to the phase envelope, the facility’s productivity increases.

How throughput optimization works. In throughput optimization, the targeted software application communicates with the controller running the plant or facility to provide a physics-based way to optimize the processing of fluids to avoid process upsets, and solves issues caused by failing to operate in the proper phase and/or the formation of hydrate or ice particles. As a result, the automated tuning control solution allows operations engineers to easily and reliably control the process to optimize operations based on real-time conditions and composition. This can measurably reduce energy costs in an array of applications, including:

- Avoiding hydrate formation in piping as the oil and gas comes out of the ground

- Ensuring liquids do not form in the piping as product flows to its consumption destination

- Monitoring the temperature in sulfur recovery units (SRUs).

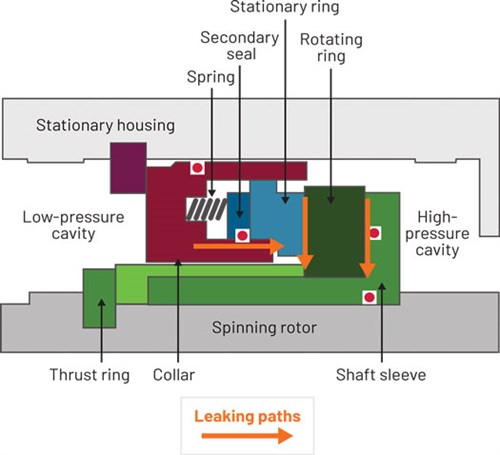

For example, FIG. 2 shows a cutaway of a centrifugal compressor on a natural gas pipeline or processing plant that uses dry gas seals. A microscopically thin film of gas provides lubrication and separation for the rotating elements. During startup and shutdown—particularly quick-stop and sudden shutdowns—the pressure and temperature of the gas film may move into the liquid phase envelope. A single, microscopic drop of fluid in the dry gas seal can destroy the seal.

|

| FIG. 2. A cutaway of a centrifugal compressor on a natural gas pipeline or processing plant that uses dry gas seals. |

Throughput optimization can identify if the potential for this exists, and, if necessary, operate a heater on the dry gas seal feed to avoid the issue.

For another use-case scenario, consider an SRU in which hydrogen sulfide (H2S) is converted to elemental sulfur using the Claus process. The temperature of the furnace in the SRU is critical to proper and continuous operation but is difficult to measure due to the high temperatures, which consequently also rapidly destroy thermocouples. Throughput optimization can determine temperature based on composition and flowrate of inputs to the furnace.

The software can adjust automatically or alert an operator via a user-interface showing phase envelope and hydrate curve to make adjustments. FIGS. 3–5 show how the software demonstrates the value of understanding the phase envelope and hydrate curve in operating a thermal natural gas separation system:

|

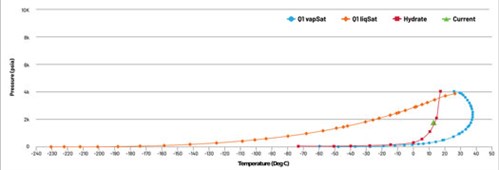

| FIG. 3. Without intelligent throughput optimization control, the process conditions are crossing the hydrate curve. |

|

| FIG. 4. The process conditions are so close to the vapor saturation curve that little if any liquid is forming, minimizing the effectiveness of the separator. |

|

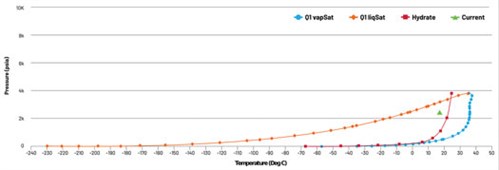

| FIG. 5. With closed-loop intelligent throughput process control, the process is operating at an optimal point in the phase envelope for liquid dropout. |

- FIG. 3: Without intelligent throughput optimization control, the process conditions are crossing the hydrate curve. Without action, hydrates will form, eventually causing vessels and piping to plug and the process to be shutdown.

- FIG. 4: Without intelligent throughput optimization control, the process conditions are so close to the vapor saturation curve that little if any liquid is forming, minimizing the effectiveness of the separator.

- FIG. 5: With closed-loop intelligent throughput process control, the process is operating at an optimal point in the phase envelope for liquid dropout.

Real-world results. By gaining real-time insights from the two-phase envelope, producers can:

- Increase throughput—By understanding where the process is operating in relation to the phase envelope and hydrate curves, processes can be tuned to produce more output.

- Increase reliability—By understanding the phase envelope and hydrate curve, facilities can be operated to avoid mixed-phase operation and avoid hydrates, which leads to stable operation and less wear and tear on equipment.

- Reduce energy use—By understanding hydrate temperatures and phase envelopes, heater, refrigeration and compression use can be optimized, reducing energy use.

- Reduce emissions—Understanding process states results in a more stable facility, reducing emissions generated during instabilities and providing the inputs to optimization for minimum emissions.

Case studies. A processor shipping propane entrained in a natural gas pipeline in North America had conservatively based calculations on the lowest gas temperature of about 20°F (–7°C). This helped them gauge how much propane could be injected into the natural gas before liquid could form and collect in the low points of the pipelines, and thereby threaten compressor performance.

However, the temperatures rarely sank so low, which meant they were missing the opportunity to earn more yield. Since implementing the new simulation software, the company can use real-time, composition-based physical constants for closed-loop control and automatically set the propane injection limit factoring in the temperature. As a result, the producer can ship approximately 20% more propane throughout 90% of the year.

In another case, facility operators ran heaters around the clock to keep hydrates from forming in their natural gas piping. Throughput optimization simulation software, however, pinpointed the risks of hydration forming as next to none. This allowed the operators to reduce the use of heaters from 100% of the time to only 5%, saving more than $ 1 MM/yr in fuel costs.

Takeaway. As gas pipeline and facilities operations face mounting demands to increase throughput and reliability, producers are looking for pragmatic, cost-effective ways to improve production and efficiency. By using real-time automated tuning control solutions, producers can more effectively control processing fluids, while mitigating risks to processes, equipment and personnel. As a result, producers can maximize capacity use and better maintain operational safety and total costs. GP

|

ROSS OTTO focuses on pipeline control and optimization as a Global Engineering Manager and packaged solution champion at Sensia, a joint venture between Rockwell Automation and Schlumberger. Mr. Otto’s leads an innovation team adapting existing technologies to specific industry challenges in optimization, maintenance and emissions reduction. He previously served as a technical specialist and program manager for Rockwell Automation. Before coming to the automation world, Mr. Otto spent many years designing and delivering pipeline SCADA, leak detection and optimization systems. With more than 35 yr of experience, he is a trusted source for pipeline automation and optimization in the oil and gas industry.

Comments